A structure for preventing oil leakage of traction motor

A traction motor and oil leakage technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of railway environmental pollution, pollution of the motor casing, the outside of the gearbox, and large oil leakage of the motor, so as to shorten the running distance, Effects of preventing oil blow-by and reducing the clearance at the start end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

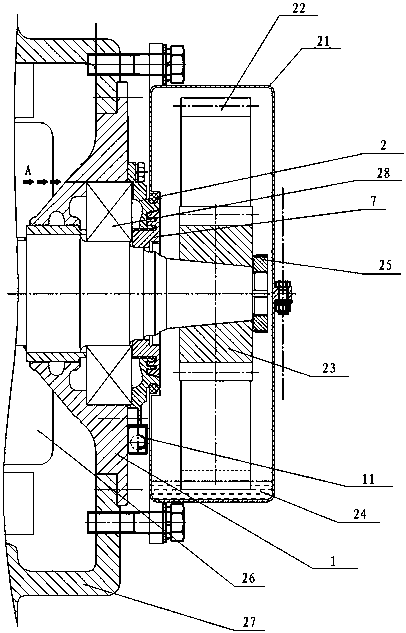

[0037] Such as figure 1 As shown, the traction motor in the present invention includes a motor chamber, a bearing chamber, and a gear box 21 . The gearbox 21 includes a pinion 23 , a bull gear 22 , and a gearbox lubricating oil 24 inside the gearbox 21 . The bearing chamber includes a rear end cover 1, a rear bearing cover 2, and a rear bearing 28, and a balance valve 11 is arranged on the rear bearing cover. The bearing chamber and the gear box 21 are sealed by a sealing ring 7 . The motor chamber includes an armature 26 and a stator 27 . The central axis pipe runs through the motor chamber, the bearing chamber and the gear box 21, and one end of the central axis is fixed by a round nut 25.

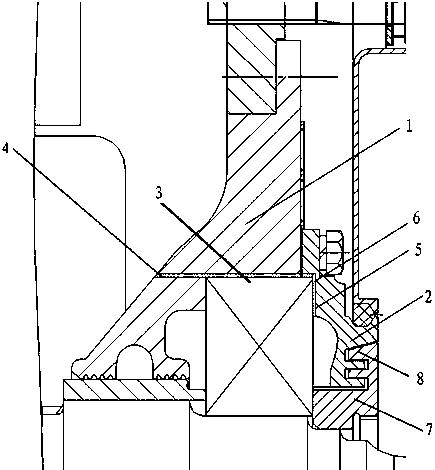

[0038] Such as figure 2 As shown, the rear end cover 1 and the rear bearing cover 2 of the trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com