Solar cell assembly used for floating on water surface

A technology on solar cells and water surfaces, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of high construction cost, high construction cost, and long construction period, and achieve the effect of prolonging the service life and preventing penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

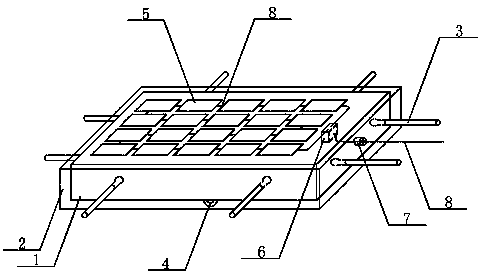

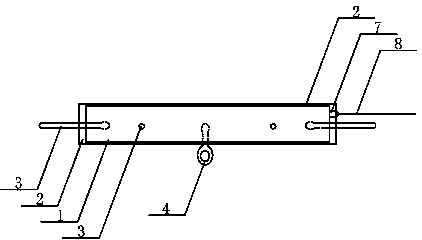

Image

Examples

Embodiment 1

[0018] Install the solar cell, junction box, waterproof sealing ring and stabilizing ring at the position set by the microporous structure foam buoyancy material, connect the solar cells together as required through conductive wires and connect them to the junction box, and output current in the junction box The conductive wires pass through the waterproof sealing ring; a sealed transparent layer with a set thickness is sprayed on the surface of the microporous structure foam buoyancy material, so that the various components are integrated together to form a solar cell module with a closed sandwich structure.

Embodiment 2

[0020] Install the solar cell, junction box, waterproof sealing ring and stabilizing ring at the position set by the closed-cell structure foam buoyancy material, connect the solar cells together as required through conductive wires and connect them to the junction box, and the junction box outputs current The conductive wires pass through the waterproof sealing ring; a sealed transparent layer with a set thickness is sprayed on the surface of the closed-cell structure foam buoyancy material, so that the various components are integrated together to form a solar cell module with a closed sandwich structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com