A soy protein preparation method

A technology of soybean protein and soybean protein, applied in vegetable protein processing and other directions, can solve the problems of poor foaming and foaming stability, and achieve the effect of good foaming stability and good foaming performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

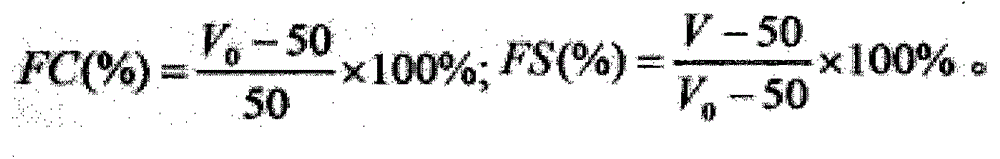

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Heat the aqueous solution of soybean protein (10g / 100mL) at pH 4.8 and temperature 70°C for 18 minutes, and then at pH 5.6 and temperature 80°C for 30 minutes;

[0026] (2) adding 1.7% Rhizomucor miehei (activity is 600000U / g) of soybean protein and 8% sodium carboxymethylcellulose of soybean protein, stirring for 85min under pH5.3 condition, and then under pH6 condition Stir for 70min;

[0027] (3) Inactivate the enzyme in a water bath at 95°C for 15 minutes, cool to 10°C, adjust the pH to 6, and sonicate for 20 minutes at 12°C and 450 rpm;

[0028] (4) Freeze-dry at -45°C for 20 minutes.

Embodiment 2

[0030] (1) Heat the aqueous solution of soybean protein (15g / 100mL) at pH 4.5 and temperature 75°C for 20 minutes, and then at pH 5.5 and temperature 85°C for 25 minutes;

[0031] (2) adding 2% Rhizomucor miehei (activity is 600000U / g) of soybean protein and 5% sodium carboxymethyl cellulose of soybean protein, stirring 95min under pH5 condition, and then under pH5.5 condition Stir for 75 minutes;

[0032] (3) Inactivate the enzyme in a water bath at 95°C for 15 minutes, cool to 15°C, adjust the pH to 5, and sonicate for 20 minutes at 10°C and 400 rpm;

[0033] (4) Freeze-dry at -40°C for 30 minutes.

Embodiment 3

[0035] (1) Heat the aqueous solution of soybean protein (5g / 100mL) at pH 5 and temperature 65°C for 15 minutes, and then at pH 5.5 and temperature 85°C for 25 minutes;

[0036] (2) adding 1.5% Rhizomucor miehei (activity is 600000U / g) of soybean protein and 3% sodium carboxymethyl cellulose of soybean protein, stirring 95min under pH5.5 condition, and then stirring at pH5.5 Stir for 75min under the condition;

[0037] (3) Inactivate the enzyme in a water bath at 95°C for 15 minutes, cool to 15°C, adjust the pH to 5, and sonicate for 15 minutes at 15°C and 500 rpm;

[0038] (4) Freeze-dry at -50°C for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com