Simple ultrasonic vegetable cleaning machine

An ultrasonic cleaning machine and vegetable technology, which are applied in the directions of cleaning methods, cleaning methods and utensils using liquids, food processing, etc., can solve the problems of large damage to vegetables and cannot use leafy vegetables for cleaning, etc., and achieve less damage to vegetables and increase ultrasonic waves. effect, the effect of increasing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

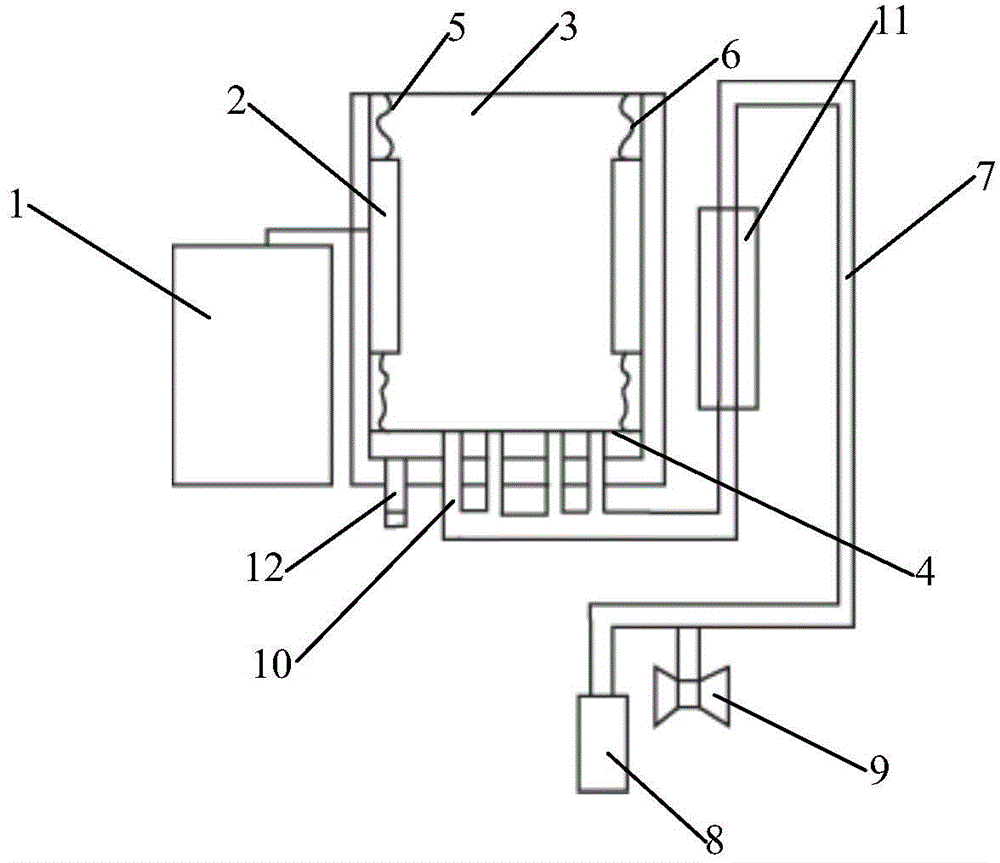

[0014] Embodiment 1: as figure 1 As shown, the present invention provides a simple ultrasonic cleaning machine for vegetables, comprising an ultrasonic source 1, an ultrasonic transducer 2, and a cleaning tank 3, the ultrasonic transducer 2 is arranged on the inner wall of the cleaning tank 3, and the The ultrasonic transducer 2 is connected with the ultrasonic generating source 1 positioned outside the cleaning tank 3 through a signal line, and is characterized in that a mesh panel 4 is provided under the inside of the cleaning tank 3, and a uniform panel 4 is arranged on the inner wall of the cleaning tank 3. The protrusions 5 and the depressions 6 are distributed alternately, and the shape of the distribution of the protrusions 5 and the depressions 6 on the inner wall of the cleaning tank 3 is wavy. The bottom of the cleaning tank 3 communicates with the air intake pipe 7, the air intake pipe 7 is connected with the air pump 8, the air valve 9 is arranged on the air intake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com