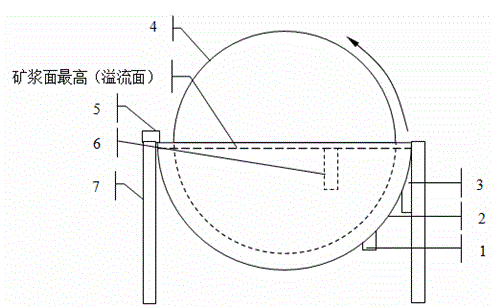

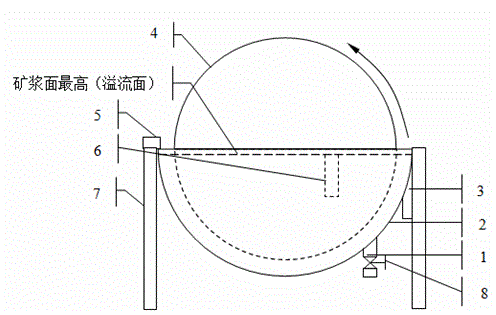

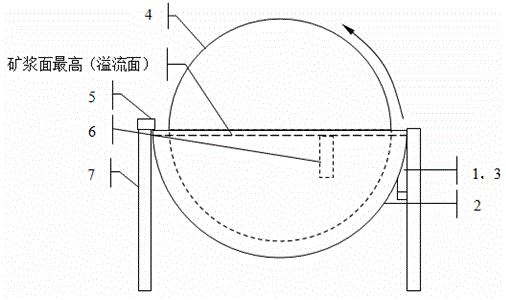

Small-section communicating pipe device and method for keeping pulp surface in wet magnetic separator tank body horizontal

A technology of wet magnetic separator and small section, which is applied in chemical instruments and methods, magnetic separation, solid separation, etc. It can solve the problems that have not been seen in the small section connecting pipe method and maintain wet magnetic separator, so as to ensure self-adaptation Sex and stability, strong adaptability and stability, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In Panzhihua Iron and Steel Midi concentrator, the average volume flow rate of non-magnetic products of each roughing magnetic separator is 180 meters 3 / hour with a minimum volumetric flow rate of 150 meters 3 / hour (equivalent to 0.042 meters 3 / Second). The concentration of this non-magnetic product is 20%, the fineness is 45%-200 mesh, the maximum particle size is 0.35 mm, and the particle density is 2700 kg / m 3 According to table 8.9-26 of "Mineral Processing Design Manual" (2007 Edition), the suspension velocity of the largest particle is 1.4 m / s. In order to ensure that the non-magnetic product does not settle when passing through the pipeline, the maximum cross-sectional area of the pipeline is (0.042 / 1.4=) 0.03 meters 2 . When a circular pipe is used to discharge the non-magnetic product, the calculated maximum diameter of the pipe is ( =0.195m=195mm, the maximum diameter of the standard size circular pipe available is 180mm (take the standard pipe). ...

Embodiment 2

[0042] In the Luoci concentrator of Kunming Iron and Steel Co., Ltd., the average volume flow rate of non-magnetic products of each weak magnetic field magnetic separator is 40 meters 3 / hour with a minimum volumetric flow rate of 30 meters 3 / hour (equivalent to 0.0084 meters 3 / Second). The concentration of this non-magnetic product is 30%, the fineness is 75%-200 mesh, the maximum particle size is 0.15 mm, and the particle density is 2600 kg / m 3 According to table 8.9-26 of "Mineral Processing Design Manual" (2007 Edition), the suspension velocity of the largest particle is 1.4 m / s. In order to ensure that the non-magnetic product does not settle when passing through the pipeline, the maximum cross-sectional area of the pipeline is (0.0084 / 1.4=) 0.006 meters 2 . When a circular pipe is used to discharge this non-magnetic product, the calculated maximum diameter of the pipe is =0.087m=87mm, the maximum diameter of the standard size circular pipe available is 83mm (t...

Embodiment 3

[0050] In a newly designed concentrator, the average volume flow rate of non-magnetic products of each magnetic separator is 30 meters 3 / hour, the pulp volume fluctuation coefficient is 1.2, and the minimum volume flow rate is (30 / 1.2=) 25 meters 3 / hour (equivalent to 0.0069 meters 3 / Second). The concentration of this non-magnetic product is 25%, the fineness is 50%-200 mesh, the maximum particle size is 0.3 mm, and the particle density is 2650 kg / m 3 According to table 8.9-26 of "Mineral Processing Design Manual" (2007 Edition), the suspension velocity of the largest particle is 1.4 m / s. In order to ensure that the non-magnetic product does not settle when passing through the pipeline, the maximum cross-sectional area of the pipeline is (0.0069 / 1.4=) 0.0049 meters 2 . When a circular pipe is used to discharge the non-magnetic product, the calculated maximum diameter of the pipe is ( = 0.079m = 79mm, the maximum diameter available for standard size circular pipes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com