Laser welding method for cambered stamping part

A technology of laser welding and stamping parts, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of welding through the pot body, the inability to realize large-scale mass production, and large size deviation, so as to avoid being welded through , to achieve the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

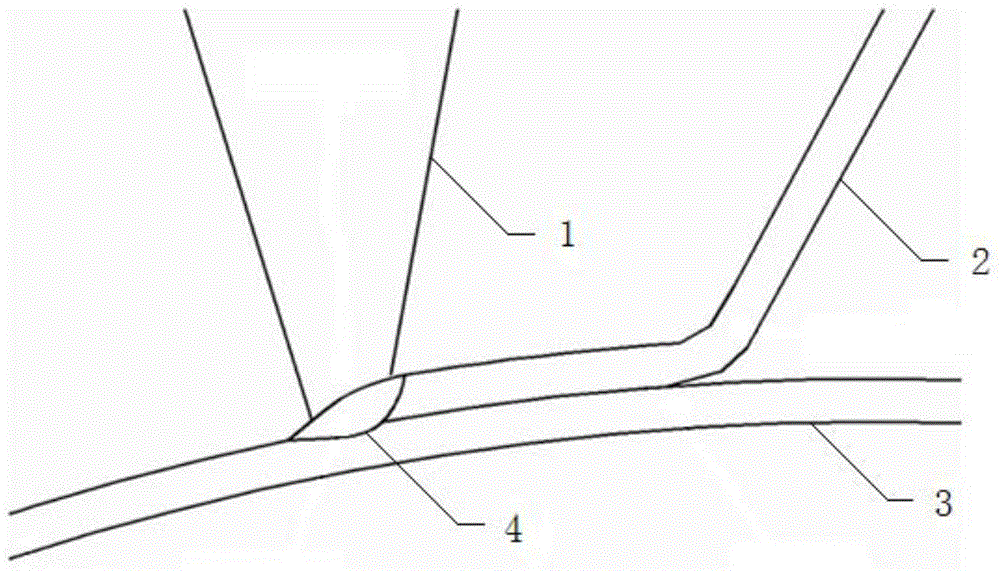

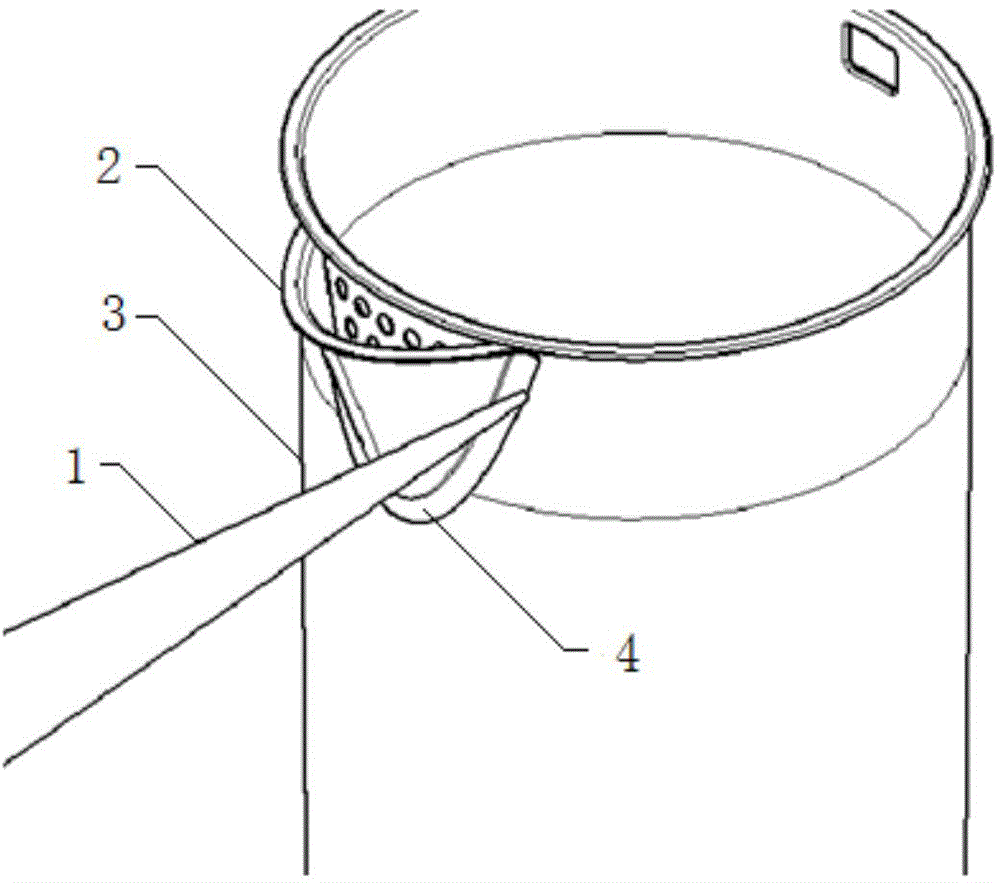

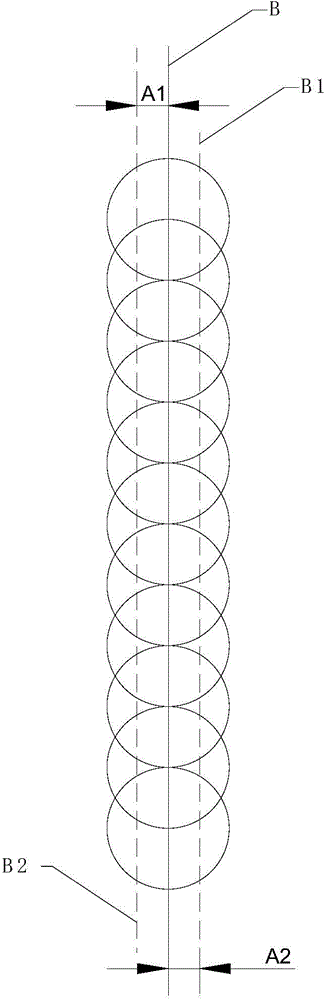

[0029] Such as image 3 As shown, B is the edge of the standard curved surface stamping part to be welded, A1 and A2 represent the position and size deviation between the curved surface stamping part to be welded and the standard curved surface stamping part at the edge to be welded, that is, the actual edge to be welded is located at B1 or B2, The welding trajectory set according to the standard curved surface stamping part is at B. Therefore, if the laser spot is too small to completely cover the position size deviation, it will cause the spot to deviate from the position where the welding should be performed and weld through the workpiece.

[0030] Curved surface stamping parts usually have a large dimensional tolerance. Taking a kettle as an example, the dimensional tolerance of the spout is about 0.4mm. Coupled with the position deviation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com