Oil discharge device for numerical control machine tool

An oil discharge device, a technology of CNC machine tools, applied in metal processing machinery parts, large fixed members, maintenance and safety accessories, etc., can solve problems such as imperfect oil discharge structure, achieve simple and effective cleaning, simple structure, and oil discharge effect. ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

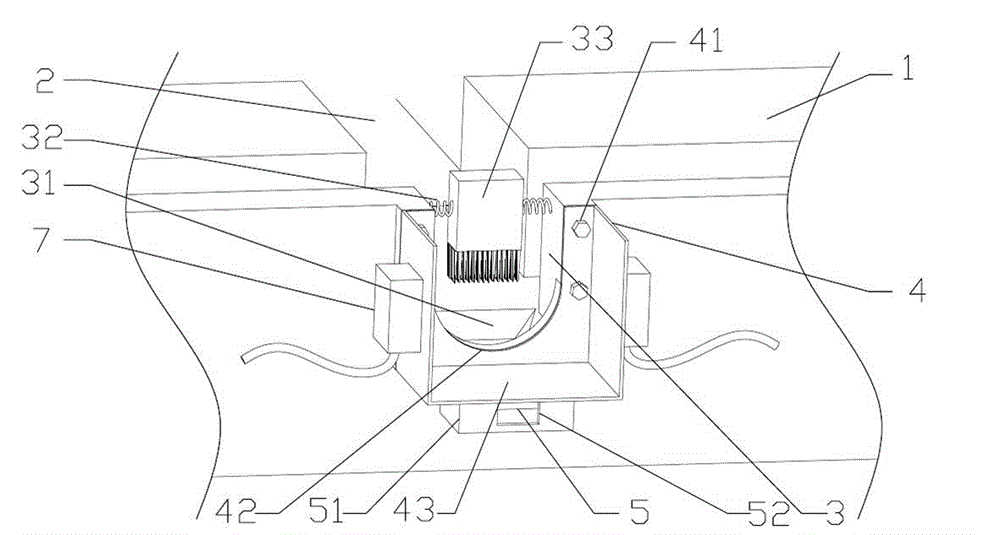

[0017] Example 1: See figure 1 , An oil discharge device for a numerically controlled machine tool, comprising a base 1, an oil guide 2 provided on the base 1, and an oil drain 3 provided on the base 1 for draining waste oil, and also includes a base 1. An oil drain base 4 for collecting and draining waste oil from the oil drain 3, a heating mechanism for thermalized waste oil provided on the oil drain base 4, and a vibration mechanism for urging the waste oil to flow out.

[0018] The oil drain base 4 includes a connecting portion 41 connected with the oil drain 3, a docking port 42 provided at the connecting portion 41 for guiding waste oil into the oil drain base 4, and a storage portion 43 for containing and draining waste oil. The connecting portion 41 can be fixed by bolts or by a snap connection, which is convenient for disassembly, assembly and replacement. The surface of the storage portion 43 is inclined downward. An oil seal layer for preventing waste oil from leaking ...

Embodiment 2

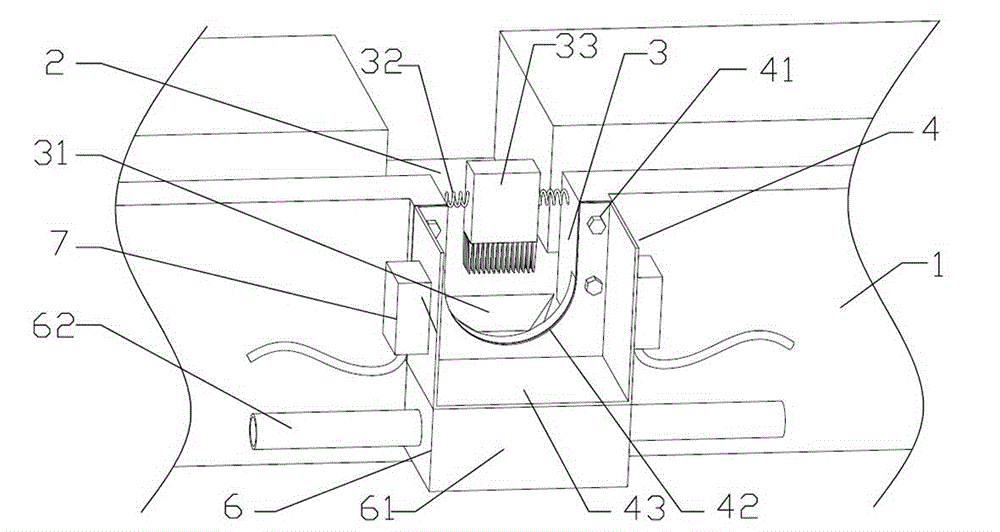

[0019] Example 2: See figure 2 , An oil discharge device for a numerically controlled machine tool, comprising a base 1, an oil guide 2 provided on the base 1, and an oil drain 3 provided on the base 1 for draining waste oil, and also includes a base 1. An oil drain base 4 for collecting and draining waste oil from the oil drain 3, a heating mechanism for thermalized waste oil provided on the oil drain base 4, and a vibration mechanism for urging the waste oil to flow out.

[0020] The oil drain base 4 includes a connecting portion 41 connected with the oil drain 3, a docking port 42 provided at the connecting portion 41 for guiding waste oil into the oil drain base 4, and a storage portion 43 for containing and draining waste oil. The connecting portion 41 can be fixed by bolts or by a snap connection, which is convenient for disassembly, assembly and replacement. The surface of the storage portion 43 is inclined downward. An oil seal layer for preventing waste oil from leakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com