A fan bone profiling processing device

A technology of profiling and fan bone, which is applied in wood processing appliances, manufacturing tools, multi-purpose machinery, etc., can solve problems such as waste of water resources and environmental pollution, and achieve the effect of improving processing efficiency and stable molding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

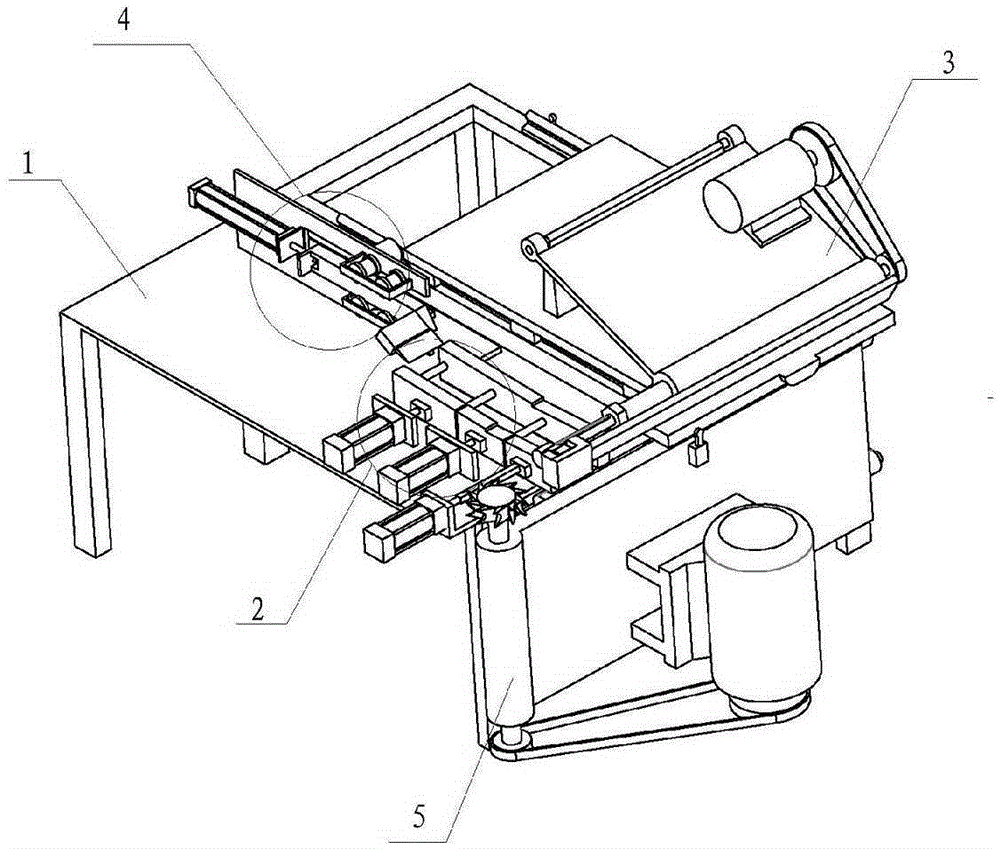

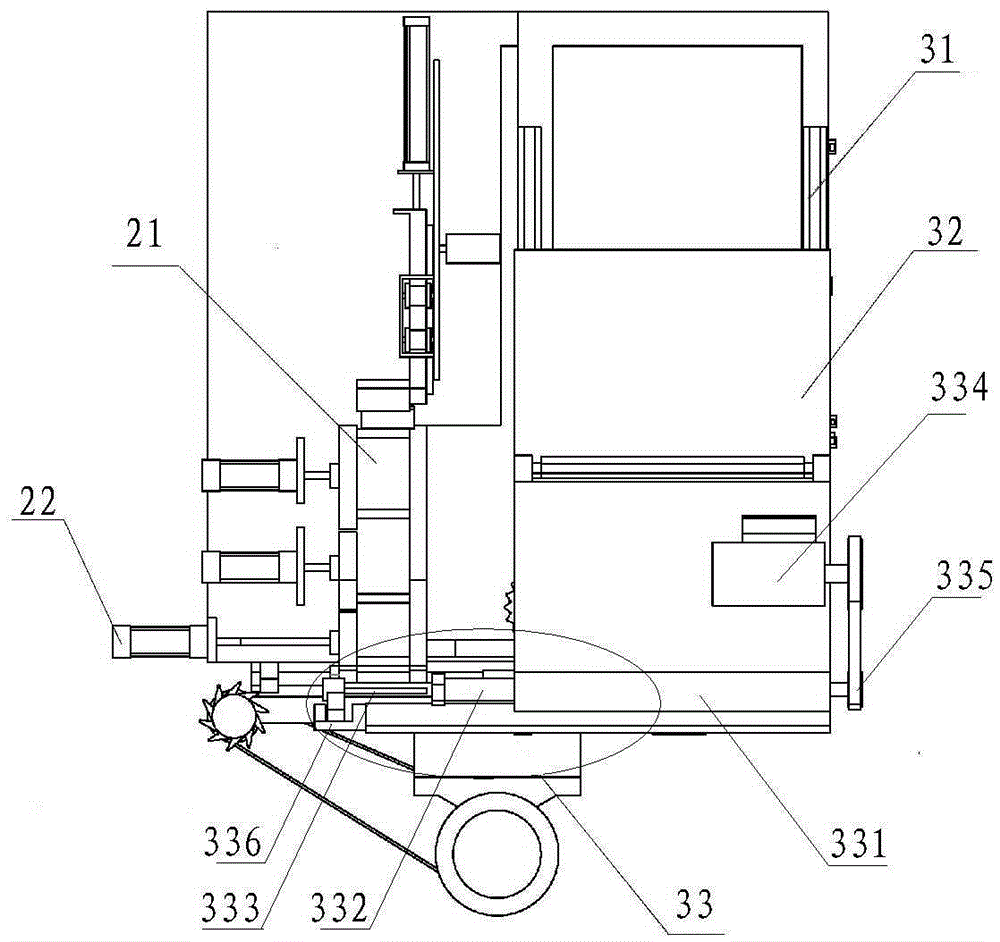

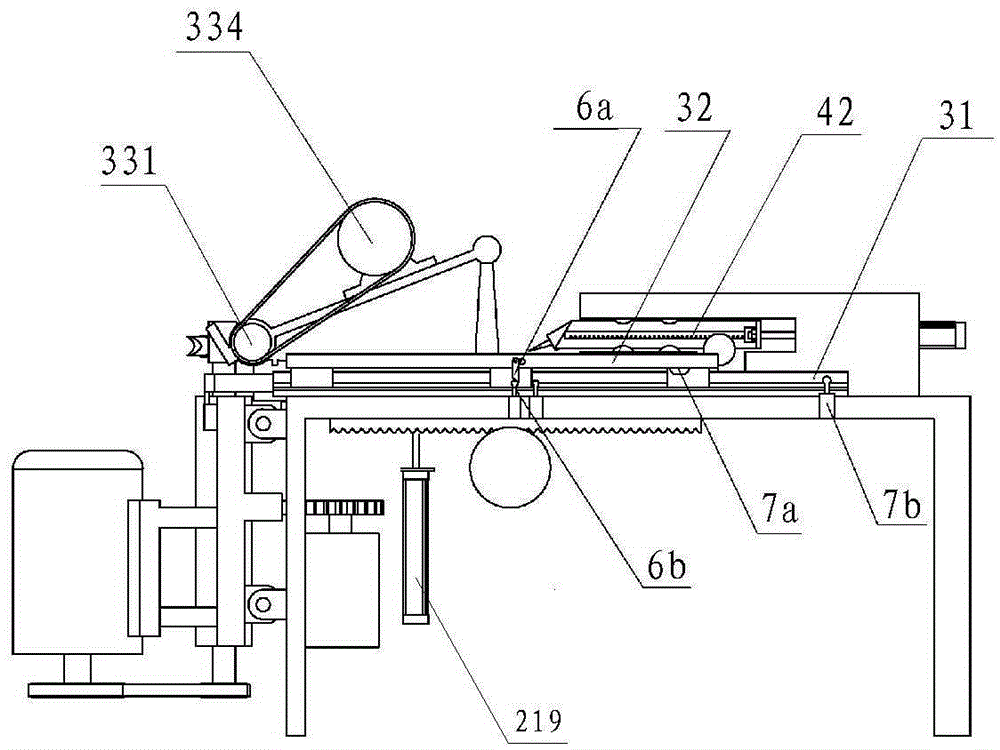

[0039] Such as Figure 1-Figure 6 As shown, the fan bone profiling processing device includes a frame 1, a feed trough 2 arranged on the frame 1, three sets of actuators and a control system for controlling the feed chute 2 and the actuators. Feed trough 2 is made of fixed plate 211 and movable plate 212, three cylinders 215 are arranged perpendicular to feed trough 21, three support bars 213 are set between fixed plate 211 and movable plate 212, and support bar 213 is set on movable plate 212 Through the feeding trough 214, the support rod 213 is provided with a supporting device for lifting and lowering the supporting rod 213 to move up and down in the feeding trough (214). Under the action of the cylinder 215, the movable plate 212 cooperates with the fixed plate 211 to compress the blank. The support device includes a support plate fixedly connected to the lower end of the support rod, and the support plate is supported by the support cylinder 219 at the lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com