Method of synthesizing hydroxyl stannate microcrystals by hydrothermal process

A hydroxystannate and hydrothermal technology, applied in chemical instruments and methods, tin compounds, inorganic chemistry, etc., can solve the problems of difficult filtration and washing, single morphology, easy adsorption of impurities, etc., and achieve easy separation and purification. , The method is simple, the effect of good shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

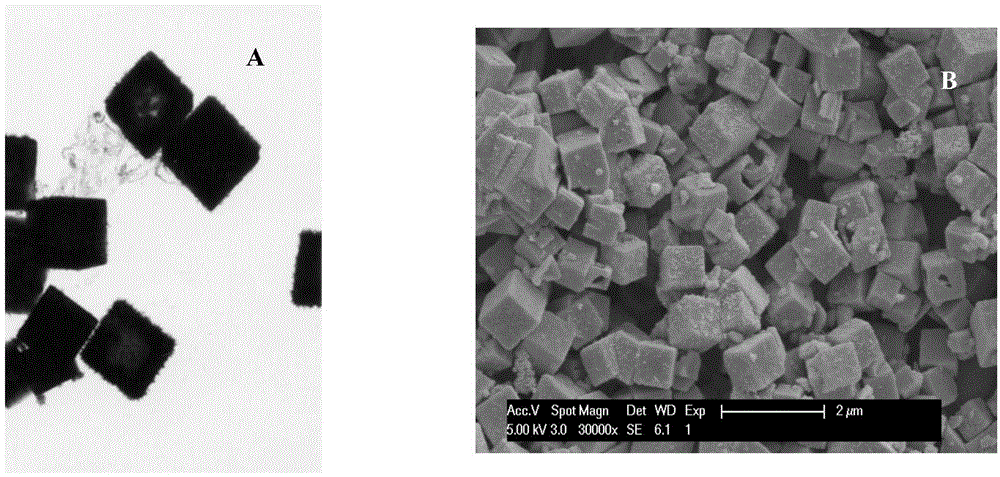

[0023] Preparation of Zinc Hydroxystannate Microcrystals:

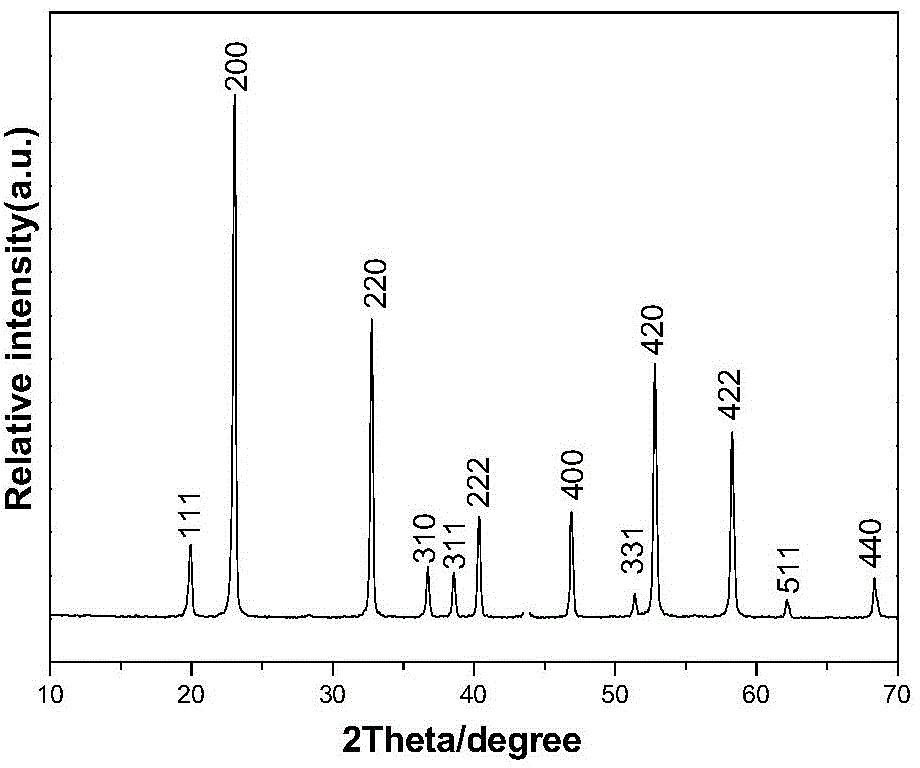

[0024] Weigh 2mmol of analytically pure SnCl 4 ·5H 2 O, 25mmol analytically pure NaOH, 0.2mmol analytically pure ZnCl 2 , were added to a small beaker filled with 10mL of distilled water, dissolved under the condition of magnetic stirring, respectively to obtain SnCl 4 ·5H 2 O solution, NaOH solution and ZnCl 2 solution; under the condition of magnetic stirring, the SnCl 4 ·5H 2 The O solution was slowly added dropwise to the NaOH solution until a stable and transparent solution was formed, and then the ZnCl 2 Add the solution dropwise to the above transparent solution until a stable suspension is formed; transfer the suspension into a high-pressure reaction kettle with a polytetrafluoroethylene liner, add distilled water to 80% of the entire volume, and seal it Put it in an electric heating oven, control the temperature at 140°C, and the reaction time is 12 hours; after the reaction stops, wait for the high-pr...

Embodiment 2

[0027] Preparation of Calcium Hydroxystannate Microcrystals:

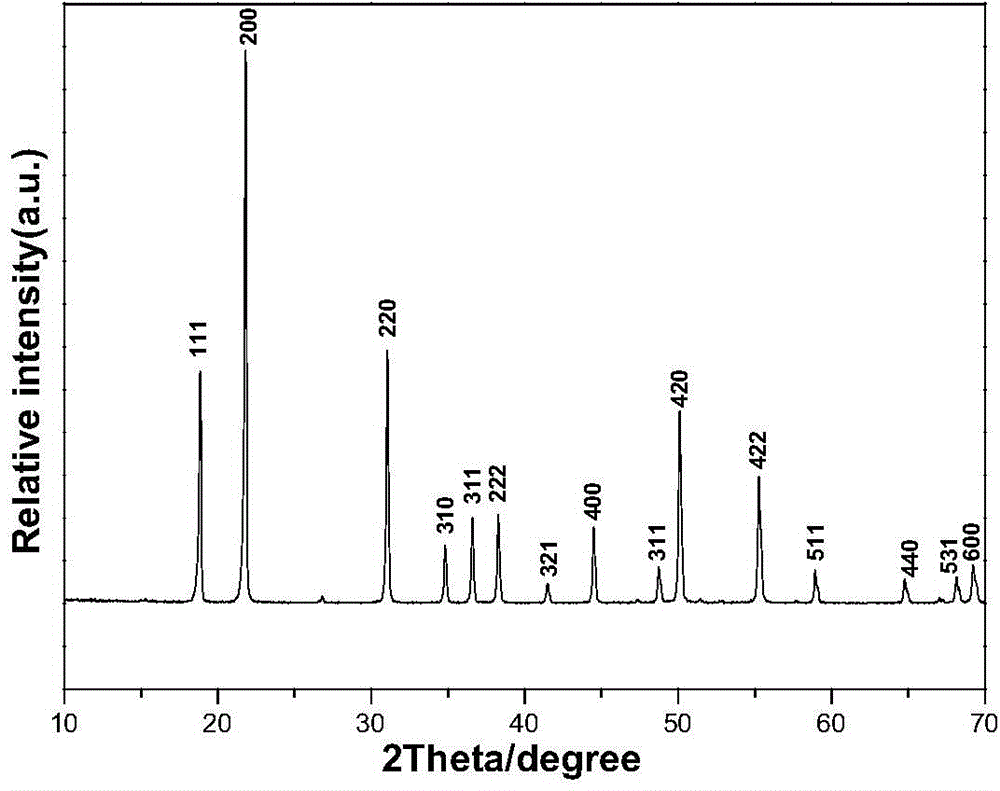

[0028] Weigh 3mmol of analytically pure SnCl 4 ·5H 2 O, 30mmol analytically pure NaOH, 0.3mmol analytically pure CaCl 2 , respectively added to a small beaker containing 15mL of distilled water, dissolved under the condition of magnetic stirring, respectively to obtain SnCl 4 ·5H 2 O solution, NaOH solution and CaCl 2 solution; under the condition of magnetic stirring, the SnCl 4 ·5H 2 The O solution was slowly added dropwise to the NaOH solution until a stable and transparent solution was formed, and then the CaCl 2 Add the solution dropwise to the above transparent solution until a stable suspension is formed; transfer the suspension into a high-pressure reaction kettle with a polytetrafluoroethylene liner, add distilled water to 80% of the entire volume, and seal it Put it into an electric heating oven, control the temperature at 130°C, and the reaction time is 5h; after the reaction stops, wait for the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com