A kind of preparation method of blue light coumarin film with polyvinyl alcohol as matrix

A technology of polyvinyl alcohol and methyl coumarin, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of poor film-forming uniformity, influence of research results, changing luminescent wavelength, etc., and achieve good film-forming performance and preparation The method is simple and the effect of high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

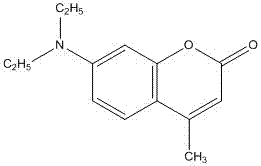

[0024] (1) Prepare 7-diethylamino-4-methylcoumarin in absolute ethanol solution

[0025] The specific preparation process is as follows: add 0.0235 g of 7-diethylamino-4-methylcoumarin to a clean and dry volumetric flask, and then add 100 ml of anhydrous ethanol solvent, and keep stirring until it is completely dissolved and a mole is obtained. The concentration is 1.0x10 -3 mol / L 7-diethylamino-4-methylcoumarin in absolute ethanol solution.

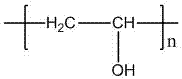

[0026] (2) Preparation of polyvinyl alcohol aqueous solution

[0027] The specific preparation process is: add 0.4991g of polyvinyl alcohol to a clean and dry test tube, then add 10 ml of deionized water, and continue to stir at 50 degrees Celsius until it is completely dissolved to obtain a polyvinyl alcohol with a mass concentration of 5% Aqueous solution.

[0028] (3) Prepare 7-diethylamino-4-methylcoumarin / polyvinyl alcohol mixed solution

[0029] The specific preparation process is as follows: use a micro-injector to measure 25 ul of the 7...

Embodiment 2

[0034] (1) Prepare 7-diethylamino-4-methylcoumarin in absolute ethanol solution

[0035] The specific preparation process is as follows: add 0.0581 g of 7-diethylamino-4-methylcoumarin to a clean and dry volumetric flask, then add 250 ml of anhydrous ethanol solvent, and keep stirring until it is completely dissolved to obtain a mole The concentration is 1.0x10 -3 mol / L 7-diethylamino-4-methylcoumarin in absolute ethanol solution.

[0036] (2) Preparation of polyvinyl alcohol aqueous solution

[0037] The specific preparation process is as follows: add 0.5002 g of polyvinyl alcohol to a clean and dry test tube, then add 10 ml of deionized water, and continue to stir at 80 degrees Celsius until it is completely dissolved to obtain a polyvinyl alcohol with a mass concentration of 5% Aqueous solution.

[0038] (3) Prepare 7-diethylamino-4-methylcoumarin / polyvinyl alcohol mixed solution

[0039] The specific preparation process is as follows: Use a micro-injector to measure 5 ul of the 7...

Embodiment 3

[0044] (1) Prepare 7-diethylamino-4-methylcoumarin tetrahydrofuran solution

[0045] The specific preparation process is as follows: add 0.0225 g of 7-diethylamino-4-methylcoumarin to a clean and dry beaker, then add 100 ml of tetrahydrofuran solvent, and keep stirring until it is completely dissolved and the molar concentration is 1.0 x10 -3 mol / L 7-diethylamino-4-methylcoumarin tetrahydrofuran solution.

[0046] (2) Preparation of polyvinyl alcohol aqueous solution

[0047] The specific preparation process is: add 1.003 g of polyvinyl alcohol to a clean and dry test tube, then add 20 ml of deionized water, and continue to stir at 60 degrees Celsius until it is completely dissolved to obtain a polyvinyl alcohol with a mass concentration of 5% Aqueous solution.

[0048] (3) Prepare 7-diethylamino-4-methylcoumarin / polyvinyl alcohol mixed solution

[0049] The specific preparation process is as follows: use a micro-injector to measure 50 ul of the 7-diethylamino-4-methylcoumarin tetrah...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com