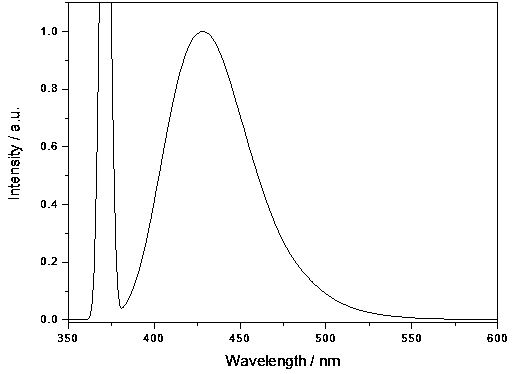

Preparation method of blue-ray coumarin film with polyvinyl alcohol as substrate

A technology of polyvinyl alcohol and methyl coumarin, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of changing luminous wavelength, poor uniformity of film formation, and influence of research results, etc., and achieves high light transparency and film formation The effect of good performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

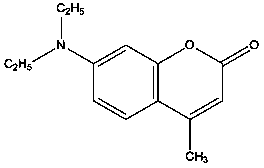

[0028] (1) Preparation of 7-diethylamino-4-methylcoumarin absolute ethanol solution

[0029] The specific process of preparation is: add 0.0235 g of 7-diethylamino-4-methylcoumarin into a clean and dry volumetric flask, then add 100 ml of absolute ethanol solvent, and keep stirring until it is completely dissolved to obtain mole Concentration is 1.0x10 -3 mol / L 7-diethylamino-4-methylcoumarin absolute ethanol solution.

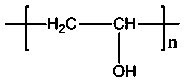

[0030] (2) Preparation of polyvinyl alcohol aqueous solution

[0031] The specific process of preparation is: add 0.4991g polyvinyl alcohol into a clean and dry test tube, then add 10 ml deionized water, and keep stirring at 50 degrees Celsius until it is completely dissolved to obtain polyvinyl alcohol with a mass concentration of 5%. aqueous solution.

[0032] (3) Preparation of 7-diethylamino-4-methylcoumarin / polyvinyl alcohol mixed solution

[0033] The specific process of preparation is: use a micro-injector to measure 25 ul of 7-diethylamino-4-methy...

Embodiment 2

[0038] (1) Preparation of 7-diethylamino-4-methylcoumarin absolute ethanol solution

[0039] The specific process of preparation is: add 0.0581 g of 7-diethylamino-4-methylcoumarin into a clean and dry volumetric flask, then add 250 ml of absolute ethanol solvent, and keep stirring until it is completely dissolved to obtain mole Concentration is 1.0x10 -3 mol / L 7-diethylamino-4-methylcoumarin absolute ethanol solution.

[0040] (2) Preparation of polyvinyl alcohol aqueous solution

[0041] The specific process of preparation is: add 0.5002 g of polyvinyl alcohol into a clean and dry test tube, then add 10 ml of deionized water, and keep stirring at 80 degrees Celsius until it is completely dissolved to obtain polyvinyl alcohol with a mass concentration of 5%. aqueous solution.

[0042] (3) Preparation of 7-diethylamino-4-methylcoumarin / polyvinyl alcohol mixed solution

[0043] The specific process of preparation is: use a micro-injector to measure 5 ul of 7-diethylamino-4...

Embodiment 3

[0048] (1) Preparation of 7-diethylamino-4-methylcoumarin tetrahydrofuran solution

[0049] The specific process of preparation is: add 0.0225 g of 7-diethylamino-4-methylcoumarin into a clean and dry beaker, then add 100 ml of tetrahydrofuran solvent, and keep stirring until it is completely dissolved to obtain a molar concentration of 1.0 x10 -3 mol / L solution of 7-diethylamino-4-methylcoumarin in tetrahydrofuran.

[0050] (2) Preparation of polyvinyl alcohol aqueous solution

[0051] The specific process of preparation is: add 1.003 g polyvinyl alcohol into a clean and dry test tube, then add 20 ml deionized water, and keep stirring at 60 degrees Celsius until it is completely dissolved to obtain polyvinyl alcohol with a mass concentration of 5%. aqueous solution.

[0052] (3) Preparation of 7-diethylamino-4-methylcoumarin / polyvinyl alcohol mixed solution

[0053] The specific process of preparation is: use a micro-sampler to measure 50 ul of the 7-diethylamino-4-methy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com