Constant-temperature control device and method for large workpiece flame quenching

A large workpiece, constant temperature control technology, applied in quenching device, heat treatment process control, manufacturing tools and other directions, can solve the problems of restricting the healthy development of flame surface quenching heat treatment, difficult to ensure the uniformity of flame heating, and increasing the labor intensity of operators. Achieve the effect of intelligent control of gas flow, manpower saving and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

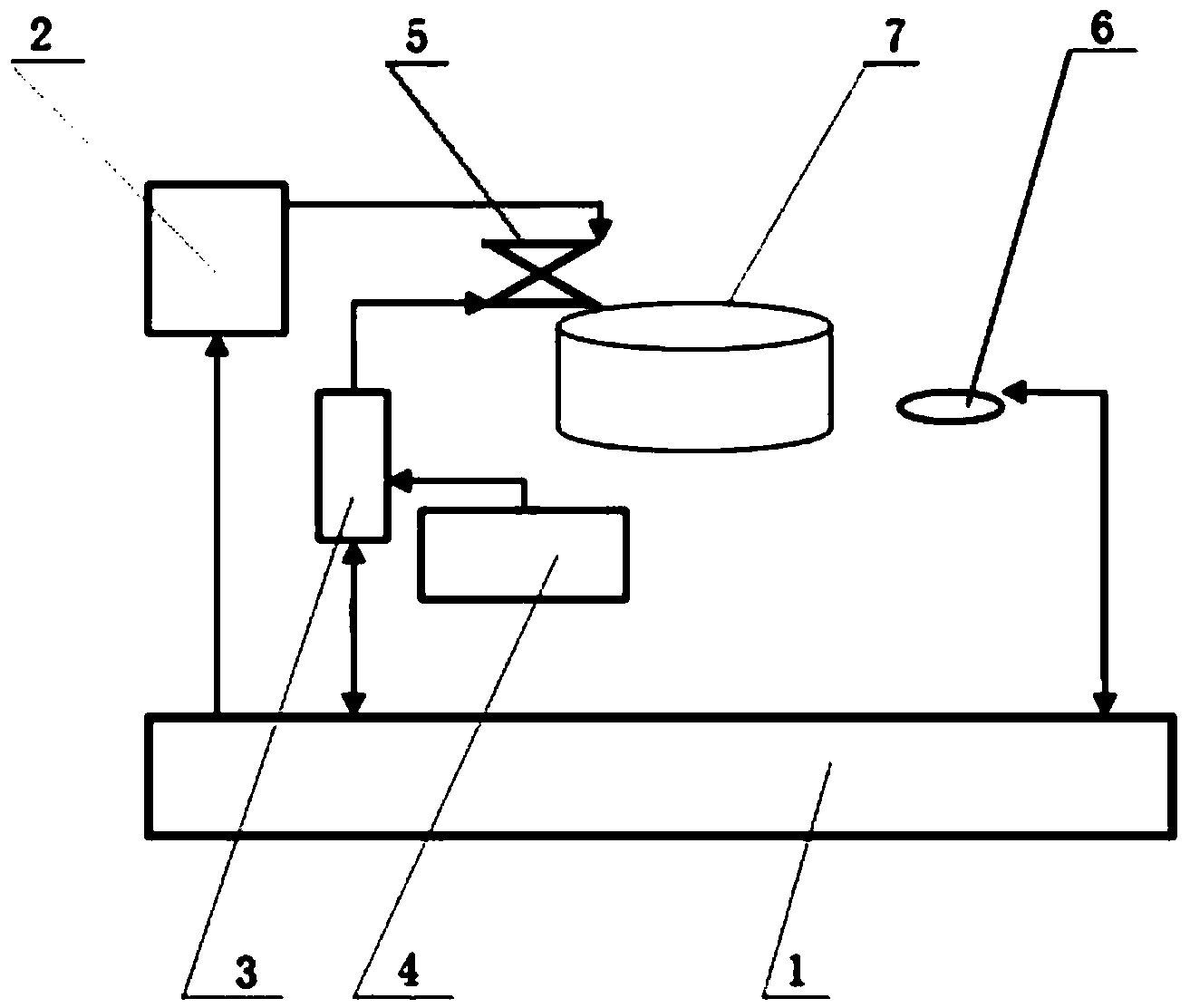

[0020] Such as figure 1 As shown, the present invention provides a constant temperature control device for flame quenching of large workpieces, including an intelligent program control driver 1, an igniter 2, a gas ratio regulator 3, a gas supply source 4, a flame nozzle 5, a non-contact heat Release infrared sensor 6 and large workpiece 7;

[0021] The gas supply source 4 is a combustible gas source;

[0022] The gas in the gas supply source 4 is ignited by the igniter 2 through the gas ratio regulator 3 and the flame nozzle 5; after the non-contact pyro-infrared sensor 6 detects and collects the heating temperature on the surface of the large workpiece 7, it is input to the intelligent program control The driver 1 performs display and comparison, and then the driver 1 is controlled by an intelligent program to control the gas proportional regulator 3 to adjust the output gas of the gas supply source.

[0023] A constant temperature control method for flame quenching of lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com