Plane-vertical-horizontal collaborative railroad bed drainage design method

A railway subgrade and collaborative design technology, applied in the direction of the road floor and buildings, can solve problems that affect work efficiency and project quality, do not consider the collaborative design of drainage ditches, and cannot meet the needs of railway construction, etc., so that the design process can be intuitive and improve Design efficiency and result quality, practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

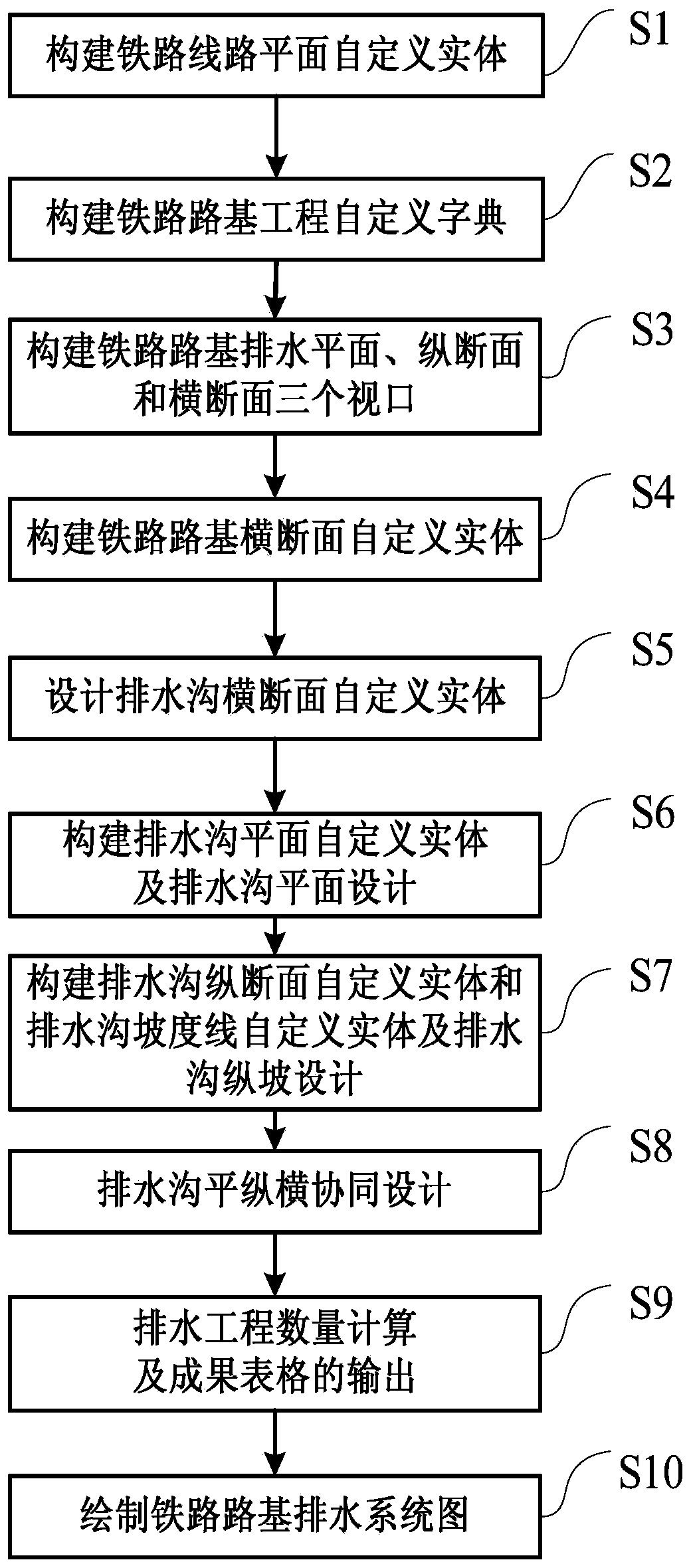

[0045] The specific technical solutions of the present invention are described with reference to the accompanying drawings. As shown in the flow chart of Fig. 1, the steps of the horizontal and vertical horizontal collaborative design method of railway embankment rows involved in the present invention include: constructing a railway line plane self-defined entity, constructing a railway embankment project custom dictionary, constructing a railway embankment drainage plane, longitudinal section and Three viewports of the cross section, build a custom entity for the cross section of the railway embankment, design a custom entity for the cross section of the drainage ditch, construct a custom entity for the plane of the drainage ditch and plan design of the drainage ditch, construct a custom entity for the longitudinal section of the drainage ditch and the slope of the drainage ditch Line self-defined entity and vertical slope design of drainage ditch, vertical and horizontal coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com