Manual feeding and returning two-way hydraulic system

A two-way hydraulic and manual technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of unsatisfactory fine-tuning effects, poor control of detailed operations, etc., and achieve strong manual adjustment adaptability, Improved accuracy and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

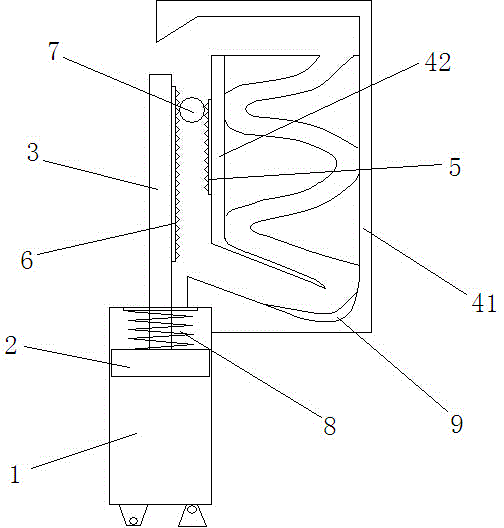

[0025] As shown in the figure, a manual forward and backward two-way hydraulic system of the present invention includes a hydraulic chamber 1, a piston system is arranged at one end of the hydraulic chamber 1, and at least two one-way valve structures are arranged at the other end, or multiple According to the actual production needs, the piston system and the two check valve structures are respectively set at both ends of the hydraulic chamber 1 to ensure that the maximum output hydraulic pressure is provided when the piston 2 moves and the hydraulic pressure of the same proportion of the two check valve structures is provided. Delivery; the piston system includes a piston 2 and a draw rod 3, the piston 2 is located in the hydraulic chamber 1, the draw rod 3 runs through the hydraulic chamber 1 and is connected to the piston 2 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com