LED module employing vacuum phase change technology and applicable to LED lighting

An LED module and LED lighting technology, applied in the field of lighting, can solve the problems of lack of super-power radiators, luminous spectrum drift, and shortened lifespan.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

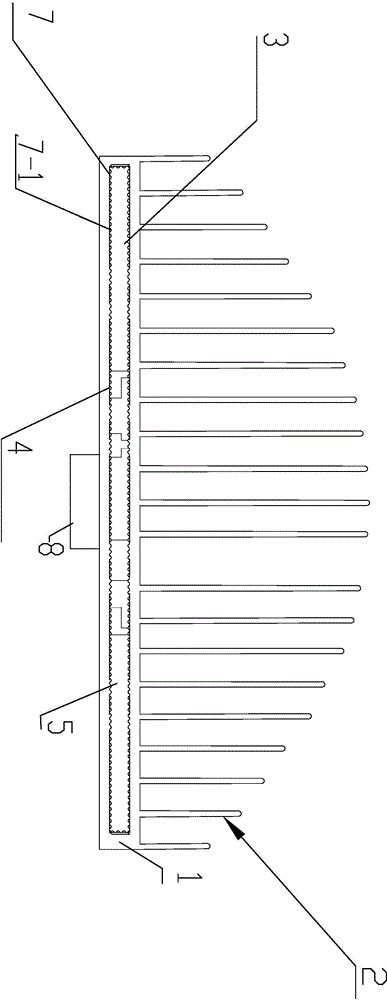

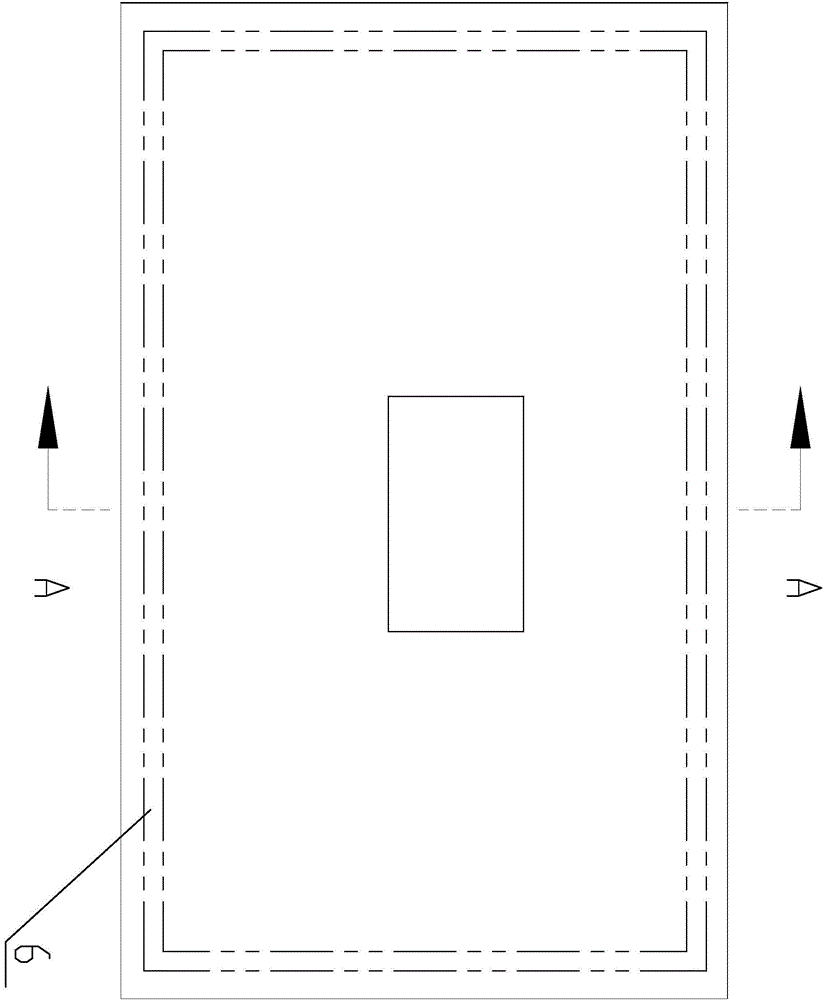

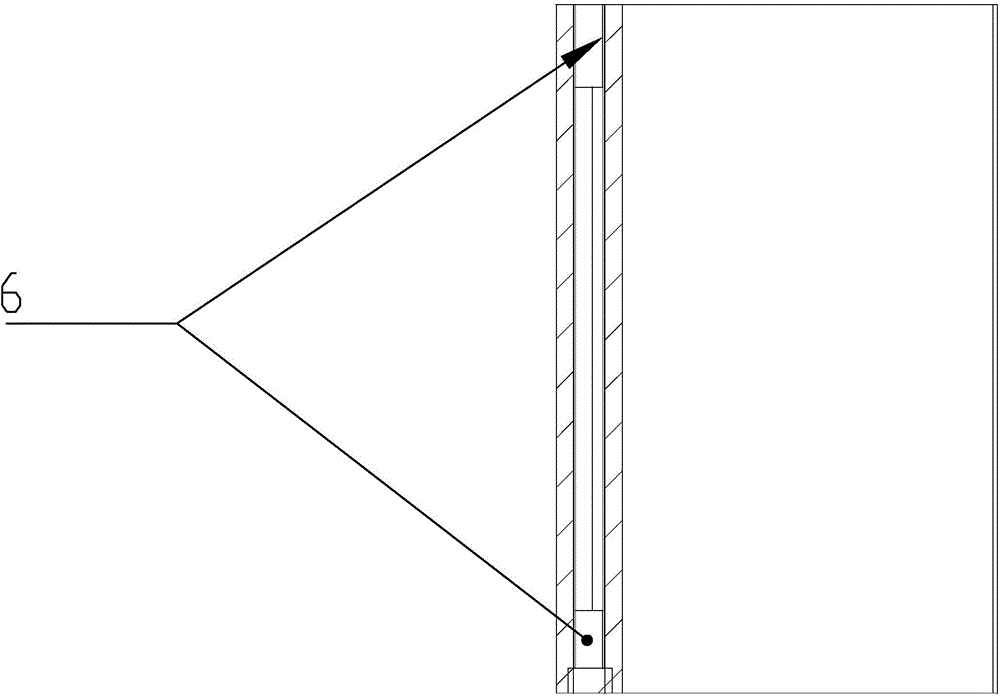

[0016] Such as figure 1 , figure 2 , image 3 As shown, the vacuum phase change technology LED module for LED lighting includes a radiator 1 and fins 2 on the LED light source 8, the radiator is a bottom plate 4 with a vacuum cavity 3 inside, and the vacuum cavity is filled with There is an ultra-low temperature medium 5; a narrow tube channel 6 is arranged in the vacuum chamber, and the narrow tube channel is a hollow tube around the vacuum chamber; a micro-groove group structure 7 is arranged on the surrounding wall of the vacuum chamber, that is, a wave-shaped slot hole 7- 1 connected groove line structure;

[0017] The boiling point of the ultra-low temperature medium is 13°C, and the vacuum strength is greater than 10 -2 support.

[0018] This module adopts vacuum phase change technology to realize rapid heat conduction and heat dissipation of the module, so as to realize the advantages of long life and low cost of the light source module. This module is compatible...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com