Method for improving nondestructive testing accuracy of carbon fiber lead

A carbon fiber wire, non-destructive testing technology, applied in the field of electric power, can solve the problems of economic loss, great safety, damage to the inner mandrel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

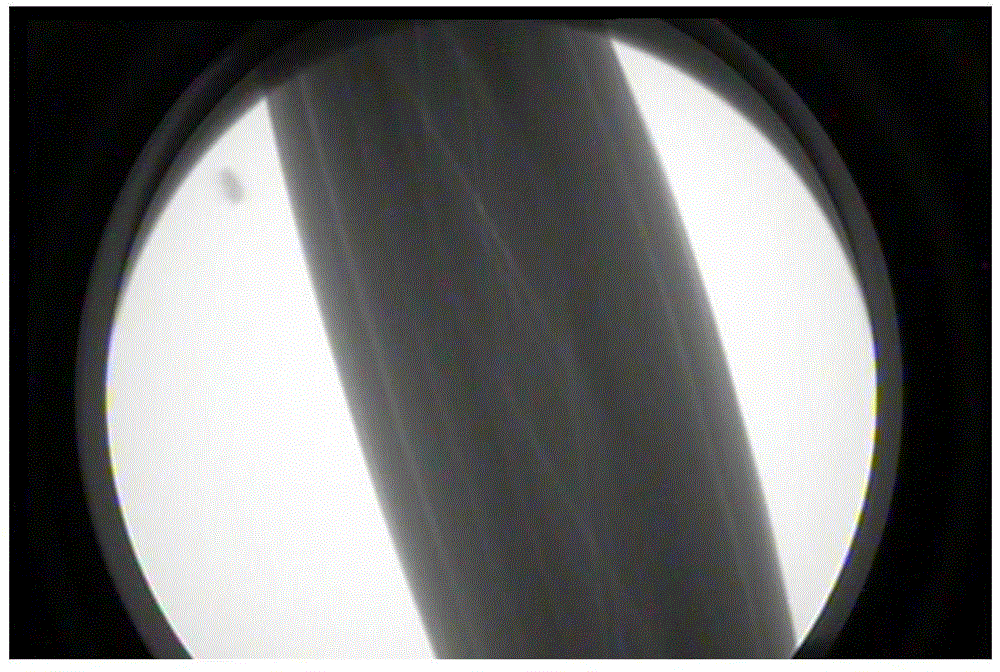

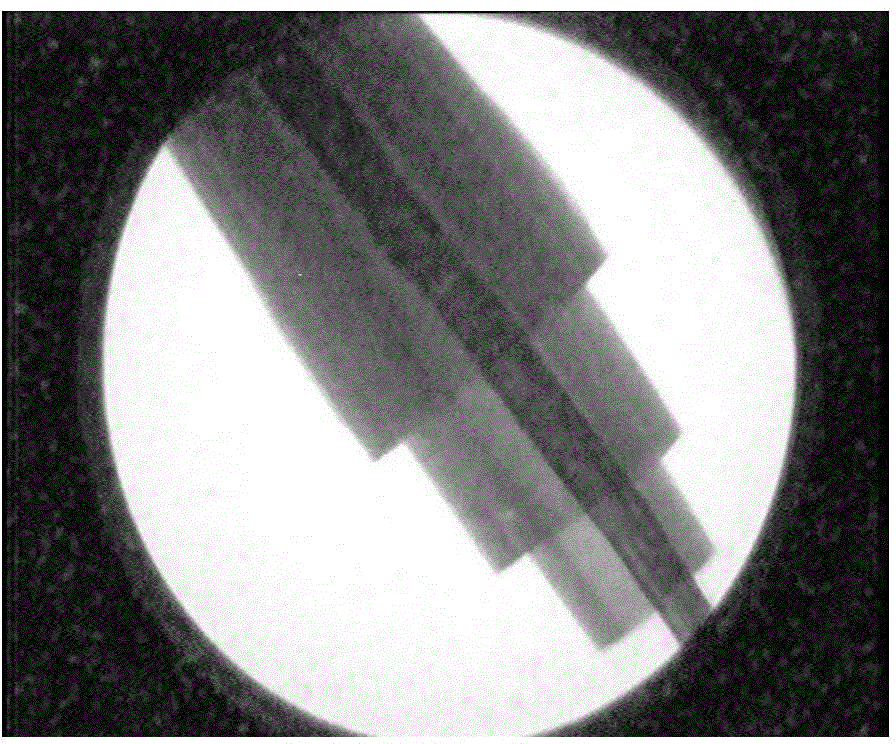

[0024] Carbon fiber is used as a reinforcing material, thermosetting resin is used as a matrix, and nanoscale heavy metal compound powder is used as a developer to produce carbon fiber composite wire mandrels. , solidified, cooled, and shaped under the traction of the tractor, and then the product is stranded to obtain the finished product. The content of the developer is 5 wt%, and the imaging effect of the internal mandrel is observed by an X-ray nondestructive testing device.

Embodiment 2

[0026] Carbon fiber is used as a reinforcing material, thermosetting resin is used as a matrix, and nanoscale heavy metal powder is used as a developer to produce carbon fiber composite wire mandrels. The details are as follows: 100 pieces of 12K carbon fiber filaments enter the preforming mold and forming mold through the glue tank with developer added. Under the traction of the tractor, it is solidified, cooled and formed, and then the product is twisted to obtain the finished product. The content of the developer is 10 wt%, and the imaging effect of the internal mandrel is observed by an X-ray nondestructive testing device.

Embodiment 3

[0028] Carbon fiber is used as a reinforcing material, thermosetting resin is used as a matrix, and nano-scale heavy metal powder is used as a developer to produce carbon fiber composite wire mandrels. The details are as follows: 66 pieces of 12K carbon fiber filaments enter the preforming mold and forming mold through the glue tank with developer added, Under the traction of the tractor, it is solidified, cooled and formed, and then the product is twisted to obtain the finished product. The content of the developer is 15 wt%, and the imaging effect of the internal mandrel is observed by an X-ray nondestructive testing device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com