Magnetic storage medium film adjustable in phase-transition temperature and coercive force and manufacturing method thereof

A technology of changing temperature and coercive force, which is applied in the field of FePt/FeRh double-layer composite magnetic storage medium film, can solve the problems of changing coercive force, etc., and achieve the effect of reducing the writing magnetic field, improving stability, and preparing materials with good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation method

[0026] 1) First, use single crystal MgO(001) as the substrate, clean it in alcohol with an ultrasonic cleaning device, and dry it with compressed air. Use tweezers to install the dried MgO(001) substrate on the sample holder of the magnetron sputtering chamber superior.

[0027] 2) The background vacuum of the high-vacuum magnetron sputtering coating chamber is better than 2×10 -5 Pa, the working Ar gas pressure is 2.8 Pa. The film forming temperature was 400°C. The purity of Fe, Pt and Rh targets is not less than 99.9%. The growth rate of Fe and Pt was controlled by the sputtering target, and the ratio of Fe atoms and Pt atoms in the FePt layer was strictly controlled at 1:1, and 25 nm thick FePt was grown on the MgO(001) substrate.

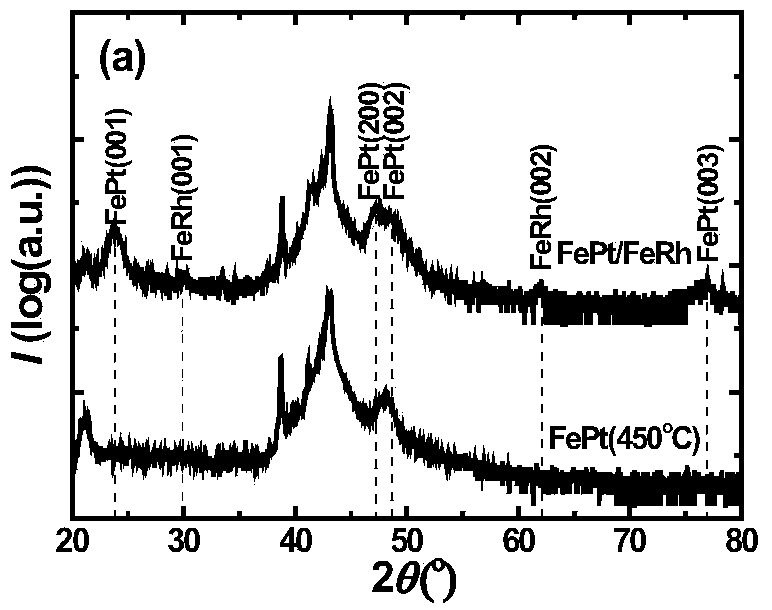

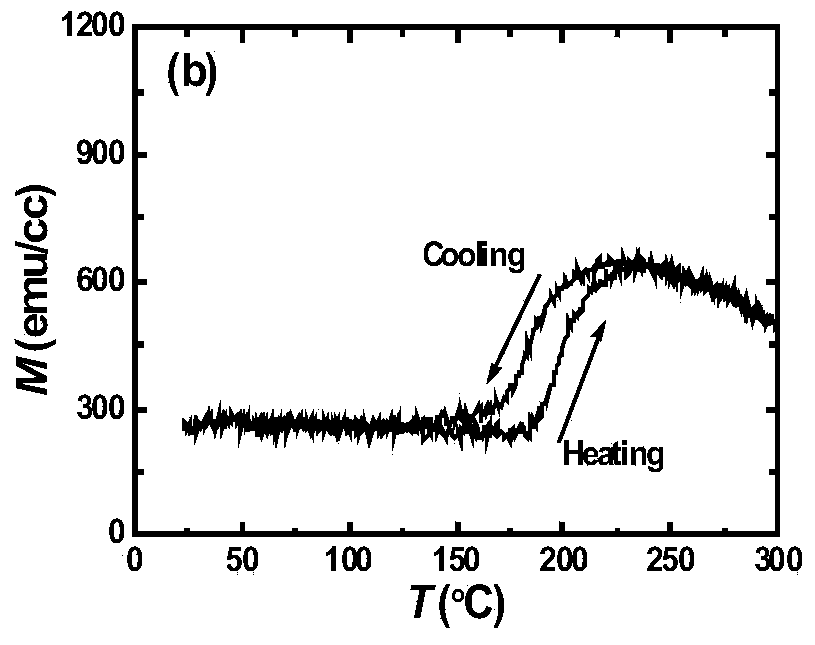

[0028] 3) After film formation, the sample was taken out and placed in a vacuum heat treatment furnace for 6 h of heat treatment at a temperature of 450 °C.

[0029] 4) Put the samples before and after heat t...

Embodiment 2

[0033] 1. Preparation method

[0034] 1) First, use single crystal MgO(001) as the substrate, clean it in alcohol with an ultrasonic cleaning device, and dry it with compressed air. Use tweezers to install the dried MgO(001) substrate on the sample holder of the magnetron sputtering chamber superior.

[0035] 2) The background vacuum of the high-vacuum magnetron sputtering coating chamber is better than 2×10 -5 Pa, the working Ar gas pressure is 2.8 Pa. The film forming temperature was 400°C. The purity of Fe, Pt and Rh targets is not less than 99.9%. The growth rate of Fe and Pt is controlled by the sputtering target, and the ratio of Fe atoms and Pt atoms in the FePt layer is strictly controlled at 1:1; 25 nm thick FePt is grown on the MgO(001) substrate.

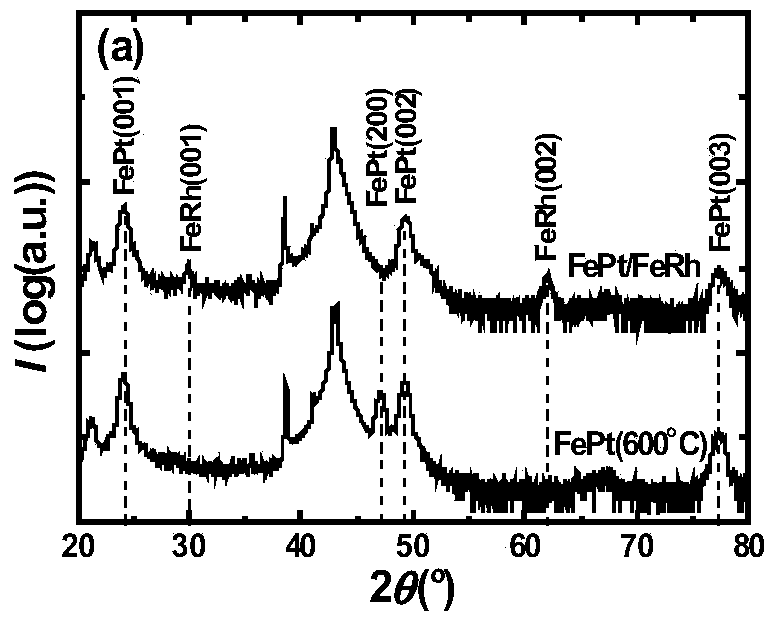

[0036] 3) After the film is formed, the sample is taken out and placed in a vacuum heat treatment furnace for 6 h of heat treatment at a temperature of 600 °C.

[0037] 4) Put the samples before and after heat treat...

Embodiment 3

[0041] 1. Preparation method

[0042] 1) First, use single crystal MgO(001) as the substrate, clean it in alcohol with an ultrasonic cleaning device, and dry it with compressed air. Use tweezers to install the dried MgO(001) substrate on the sample holder of the magnetron sputtering chamber .

[0043] 2) The background vacuum of the high-vacuum magnetron sputtering coating chamber is better than 2×10 -5 Pa, the working Ar gas pressure is 2.8 Pa. The film forming temperature was 400°C. The purity of Fe, Pt and Rh targets is not less than 99.9%. The growth rate of Fe and Pt is controlled by the sputtering target, and the ratio of Fe atoms and Pt atoms in the FePt layer is strictly controlled at 1:1; 25 nm thick FePt is grown on the MgO(001) substrate.

[0044] 3) After the film is formed, the sample is taken out and placed in a vacuum heat treatment furnace for 6 h of heat treatment at a temperature of 700 °C.

[0045] 4) Put the samples before and after heat treatment bac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com