Super capacitor module and manufacturing method thereof

A technology for supercapacitors and modules, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor terminals, multiple hybrid/electric double layer capacitors, etc. Problems such as high internal resistance can achieve the effect of canceling interference fit, stable and reliable structure, and reducing contact internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

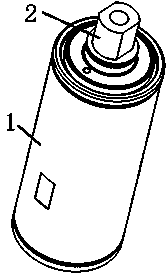

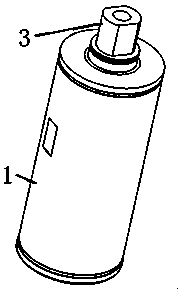

[0028] like figure 1 and figure 2 As shown, the first supercapacitor unit 1 and the negative terminal 2 of the first module form an integrated structure, the first supercapacitor unit 1 and the positive terminal 3 of the first module form an integrated structure, and the negative terminal of the first module forms an integrated structure. The shape of the connecting terminal 2 and the shape of the positive electrode connecting terminal 3 of the first module are both circular in the lower part and circular in the upper part with two arches removed.

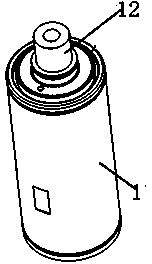

[0029] like image 3 and Figure 4 As shown, the first supercapacitor unit 1 and the second module negative terminal 12 form an integrated structure, the first supercapacitor unit 1 and the second module positive terminal 13 form an inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com