Hot water disinfection drinking system

A drinking water system and hot water technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of unqualified total number of bacteria indicators, achieve good disinfection effect, low manufacturing cost, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

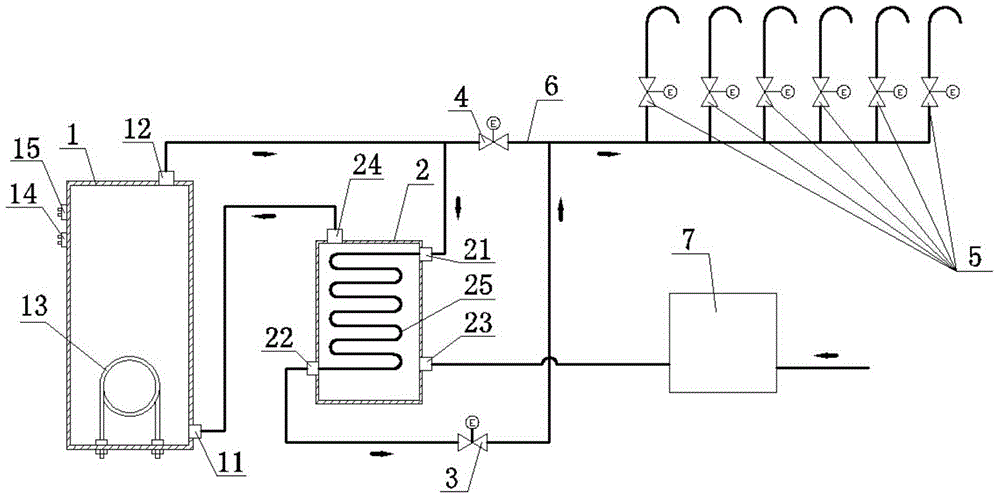

Embodiment 1

[0034] see figure 1 , The hot water disinfection drinking water system of this embodiment includes a heat tank 1, a heat exchanger 2, a first pipe switching valve 3, a second pipe switching valve 4, a water outlet valve 5, a bypass pipe 6, a purification device 7, and Electric controller.

[0035] The heating tank 1 is provided with a heating tank water inlet 11 and a heating tank water outlet 12, and a first electric heater 13 is arranged inside. The first electric heater 13 is electrically connected with the electric controller. The heating tank 1 is provided with a heating tank temperature control device 14 and a heating tank overheating protection device 15 electrically connected with an electric controller. The hot-tank temperature control device 14 is an automatically reset button-type temperature control device, or a temperature probe, or a temperature sensor. The thermal tank overheating protection device 15 is a button-type temperature control device that is manually r...

Embodiment 2

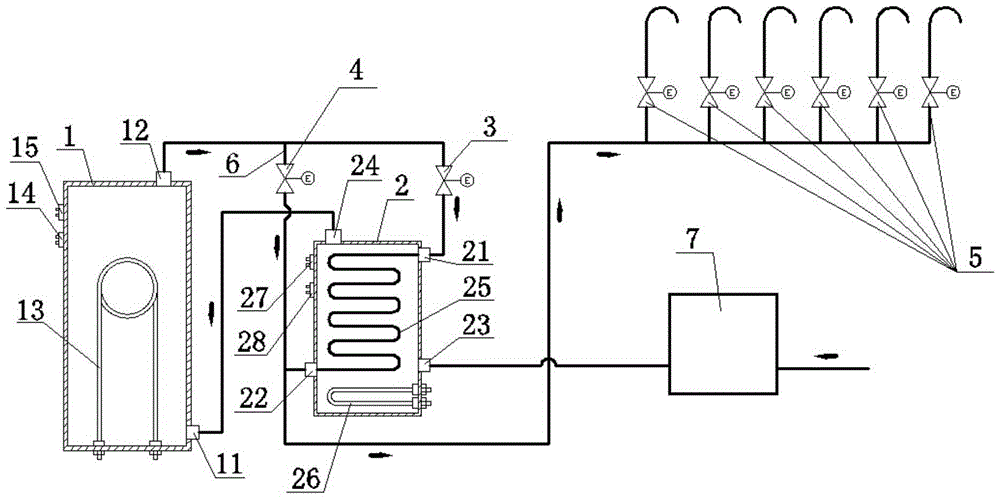

[0042] see figure 2 , This embodiment is basically the same as embodiment 1, the difference lies in:

[0043] a. A second electric heater 26 is provided inside the heat exchanger 2, and the second electric heater 26 is electrically connected to the electric controller.

[0044] b. The heat exchanger 2 is provided with a heat exchanger temperature control device 27 and a heat exchanger overheat protection device 28. The heat exchanger temperature control device 27 is an automatically reset button-type temperature control device, or a temperature probe, or a temperature sensor. The heat exchanger overheat protection device 28 is a button-type temperature control device that is manually reset, or a water probe or float switch that can detect whether there is water or not in the heat exchanger 2.

[0045] c. The first pipeline switching valve 3 is arranged on the pipeline connecting the heat tank water outlet 12 and the high temperature water inlet 21 of the heat exchanger 2.

[0046] T...

Embodiment 3

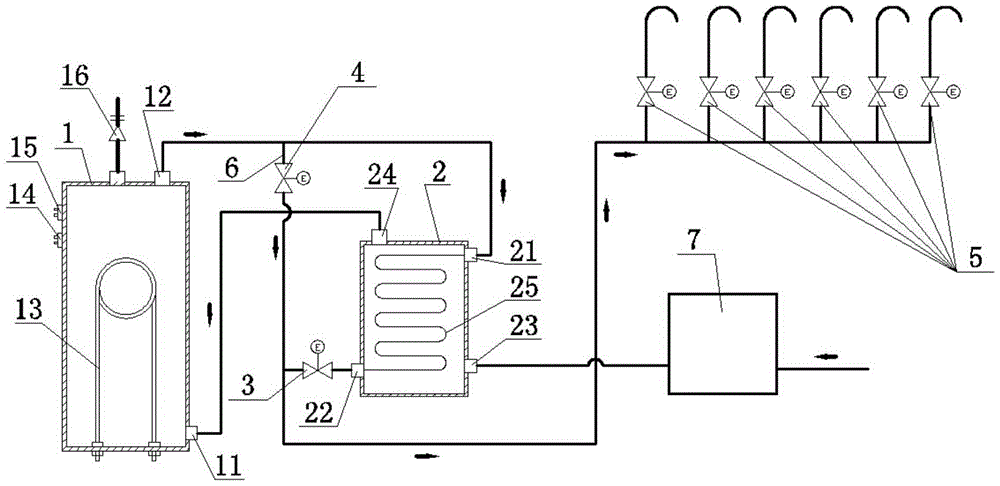

[0049] see image 3 This embodiment is basically the same as Embodiment 1, except that: a safety valve 16 is provided on the heating tank 1. The take-off pressure of the safety valve 16 on the heating tank 1 is not greater than 0.03MPa. When the pressure in the heating tank 1 reaches the lift-off pressure of the safety valve 16, the safety valve 16 jumps, opens the water release, reduces the pressure in the heating tank 1 below the set pressure, and then automatically closes.

[0050] In the hot water disinfection and drinking water system of this embodiment, the first pipe switching valve 3 is arranged in the water outlet pipe section of the heat exchange pipe 2. Because the pipe section is at a lower temperature when it is not disinfected, the high temperature resistance of the valve is reduced. Performance requirements, that is, to improve the reliability of the valve, and this change has no effect on the disinfection performance, and does not increase any cost, so this pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com