Yolk separation method and application thereof

A technology of egg yolk and mayonnaise, which is applied in the field of egg yolk separation, can solve problems that have not been reported, and achieve the effects of improving quality stability, good emulsification and viscoelasticity, and uniform distribution of lipoproteins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

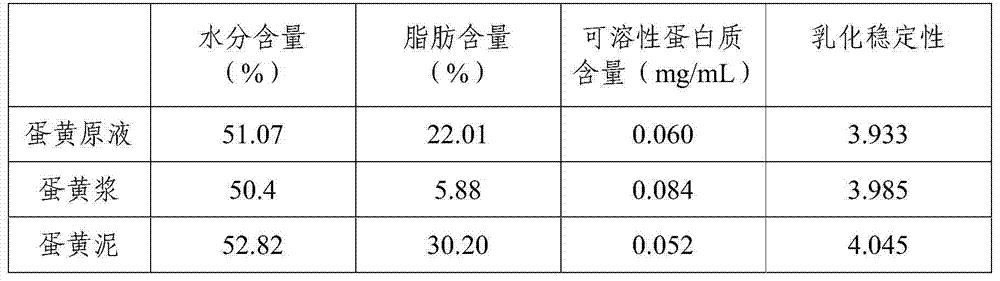

[0035] Embodiment 1: the separation of egg yolk

[0036] 1) Egg yolk homogenization treatment: wash the selected eggs in clean water, beat the eggs to remove the shells, manually separate the egg yolks, and use a high-speed disperser to homogenize the egg yolks at 6000r / min for 8 minutes to obtain the egg yolk stock solution;

[0037] 2) Egg yolk centrifugation: centrifuge the egg yolk stock solution obtained in step 1) at 10,000 r / min and 20°C for 30 minutes to obtain a two-layer separation product, the upper layer is egg yolk paste, and the lower layer is egg yolk paste.

Embodiment 2

[0038] Embodiment 2: the separation of egg yolk

[0039] 1) Egg yolk homogenization treatment: wash the selected eggs in clean water, beat the eggs to remove the shells, manually separate the egg yolks, and use a high-speed disperser to homogenize the egg yolks at 3000r / min for 10 minutes to obtain the egg yolk stock solution;

[0040] 2) Egg yolk centrifugation: centrifuge the egg yolk liquid obtained in step 1) at 12,000 r / min and 30° C. for 15 minutes to obtain two layers of centrifuged products, the upper layer is egg yolk slurry and the lower layer is egg yolk slurry.

Embodiment 3

[0041] Embodiment 3: the separation of egg yolk

[0042] 1) Egg yolk homogenization treatment: wash the selected eggs in clean water, beat the eggs to remove the shells, manually separate the egg yolks, and use a homogenizer to homogenize the egg yolks at 30Mpa for 8 minutes to obtain the egg yolk stock solution;

[0043] 2) Egg yolk centrifugation: centrifuge the egg yolk stock solution obtained in step 1) at 10,000 r / min and 20°C for 30 minutes to obtain a two-layer separation product, the upper layer is egg yolk paste, and the lower layer is egg yolk paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com