Coating producing device

A coating and dispersing device technology, applied in the directions of dissolution, mixer, chemical instruments and methods, etc., can solve the problems of reducing work efficiency and work quality, affecting the quality of coating products, affecting the work process, etc., to achieve reasonable structure and improve reliability. , the effect of increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

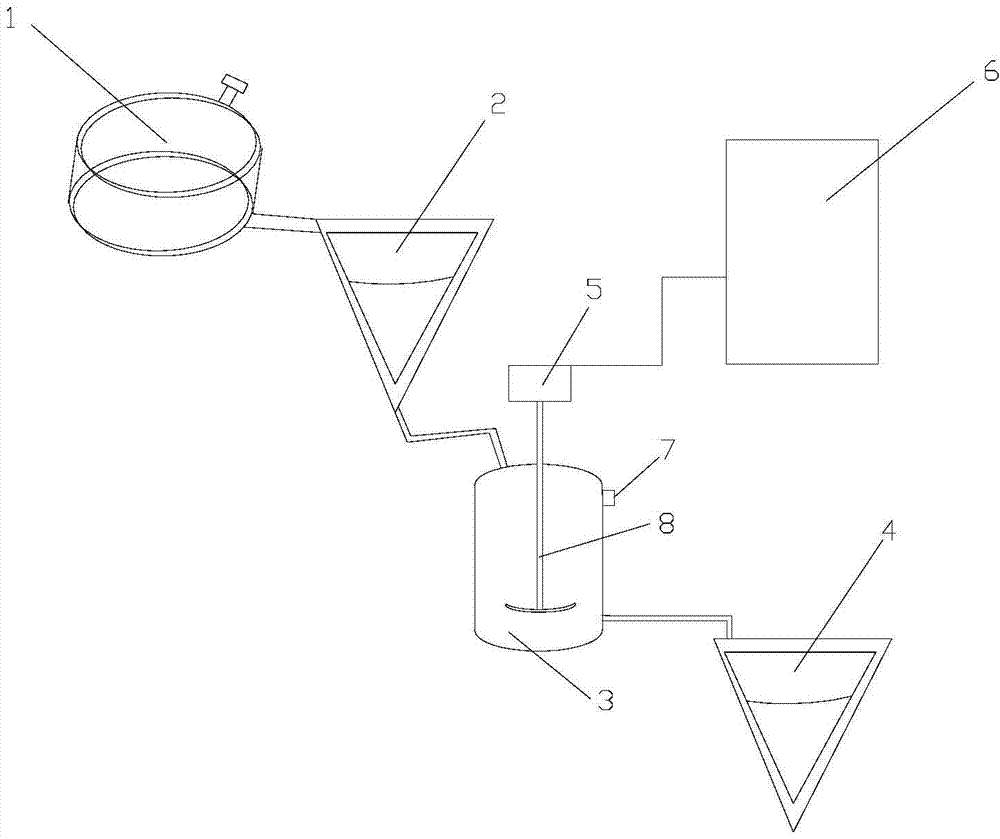

[0010] Such as figure 1 The shown a kind of device of producing coating comprises grinding machine 1, dispersing device 2, mixing tank 3 and filter 4, and the outlet of described grinding machine 1 is connected with the entrance of dispersing device 2, and described dispersing device 2 The outlet of the mixing tank 3 is connected to the inlet of the mixing tank 3, the outlet of the mixing tank 3 is connected to the inlet of the filter 4, the stirring rod 8 of the mixing tank 3 is connected to the motor 5 and controlled by the motor 5, the Motor 5 is connected with frequency converter 6 by electric wire, and described frequency converter 6 comprises signal processing unit and signal control unit, and the barrel wall of described mixing bucket 3 is provided with temperature sensor 7, and described temperature sensor 7 sends temperature signal converted into an electrical signal, and sent to the signal processing unit inside the frequency converter 6, the signal processing unit w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com