Large-span numerical control coating machine

A spraying machine and large-span technology, applied in the direction of spraying devices, etc., can solve the problems of large-format curtain spraying processing, weak processing program execution ability, affecting spraying quality and efficiency, etc., so as to improve spraying quality and efficiency, structure Simple, easy to install and lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

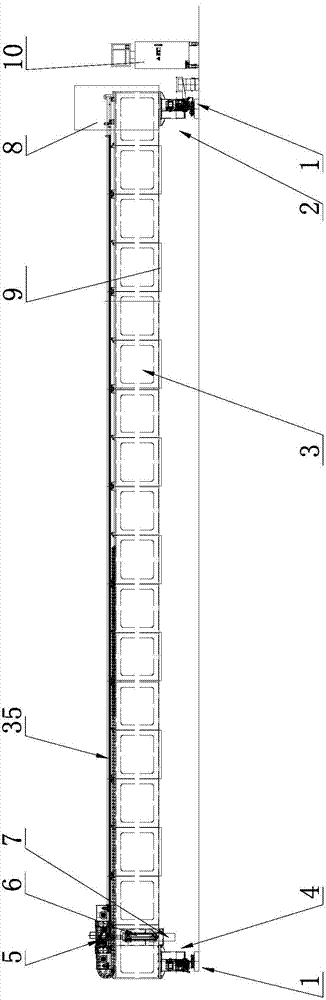

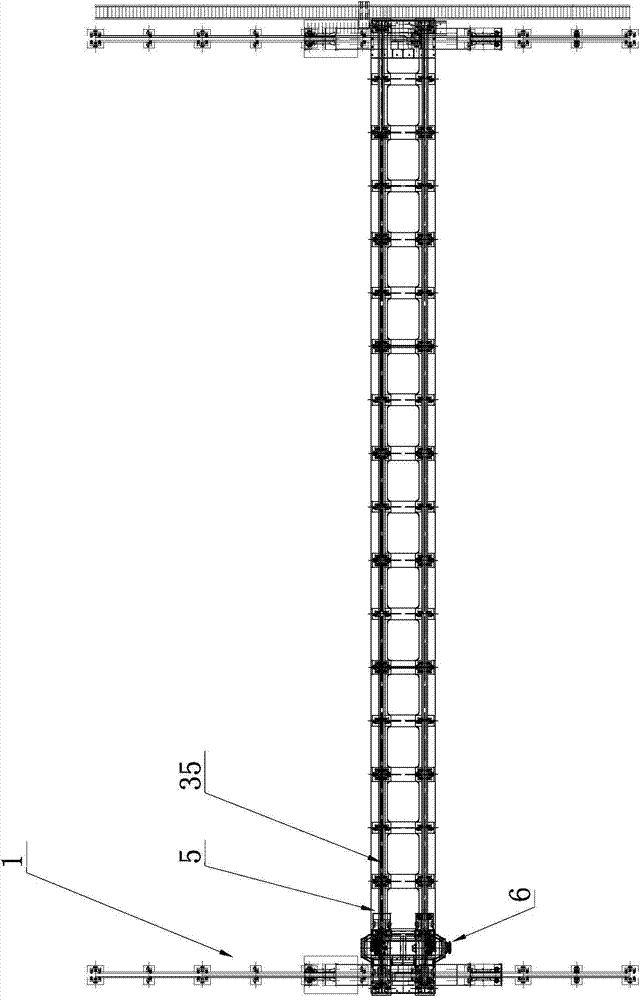

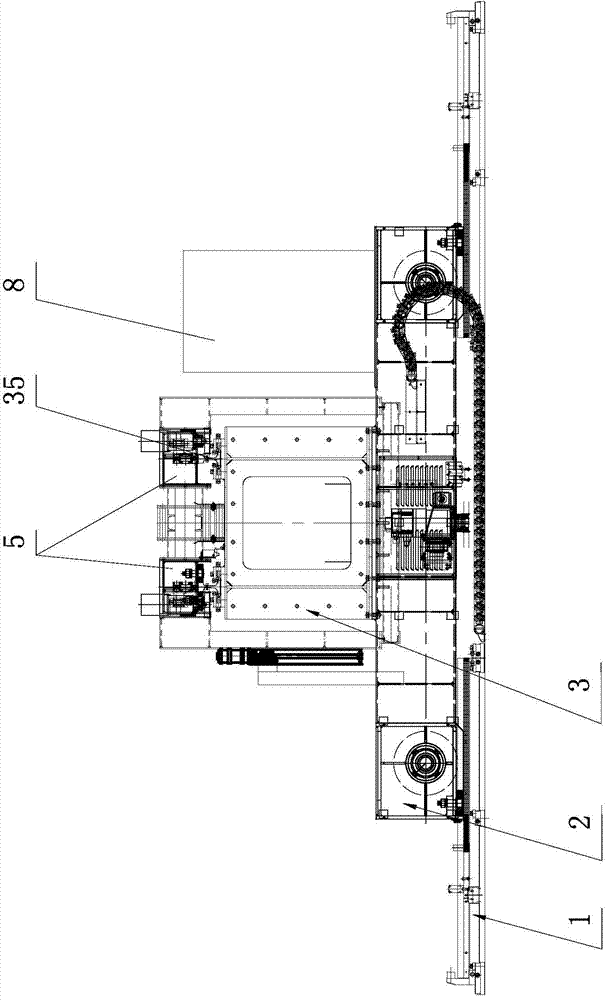

[0020] Such as figure 1 As shown, the large-span CNC spraying machine includes a group of longitudinal guide rail assemblies 1 arranged parallel to each other. The main frame drive assembly 2 and the sub-frame drive assembly 4 are controlled by a numerical control system 10, so that the main frame drive assembly 2 and the auxiliary machine The frame drive assembly 4 performs displacement movement along each group of longitudinal guide rail assemblies 1; the lower part of the crossbeam part 3 is fixedly connected with the main frame drive The transverse guide rail assemblies 35 arranged in parallel, one group of transverse frame drive assemblies 5 are controlled by the numerical control system 10, so that the transverse frame drive assemblies 5 are displaced along each group of transverse guide rail assemblies 35; on the transverse frame dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com