Multifunctional pop-up knife structure

A pop-up, multi-functional technology, applied in the direction of lathe tools, grinding tools, cutting blades, etc., can solve the problems of long turnaround time of parts, high cost, low production efficiency of enterprises, etc., achieve high flexural strength, use The effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

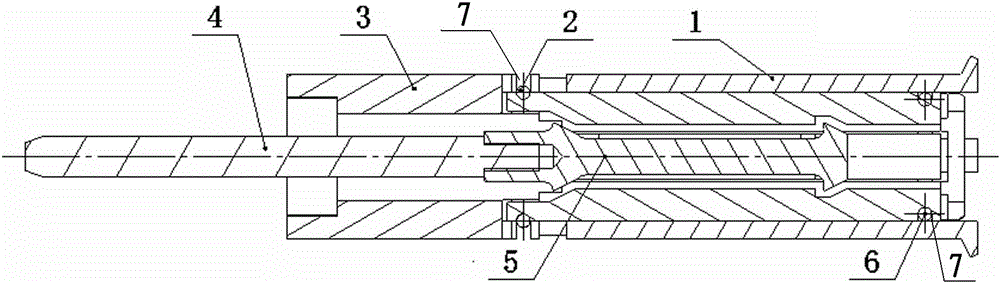

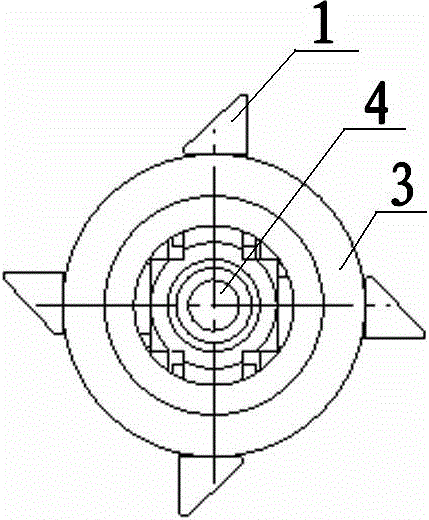

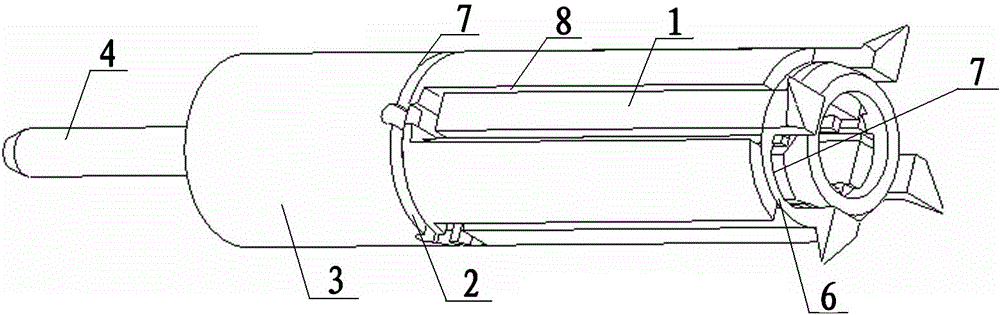

[0021] Such as Figure 1-Figure 4 As shown, the multifunctional pop-up cutter mechanism of the present invention includes a cylindrical cutter housing 3, the middle part and the front end of the cutter housing 3 are provided with U-shaped grooves 7, and the front part of the cutter housing 3 is provided with The four limiting grooves 8 having the same size and communicating with the inner cavity of the cutter housing 3 make the radial section of the inner cavity of the front end of the cutter housing 3 present a cross shape. A movable knife holder 1 is embedded in each limiting groove 8 .

[0022] The movable tool holder 1 includes a tool holder base 11 on which a cutting tool 12 is arranged, and two splints 13 are fastened on the tool holder base 11 by screws to clamp the cutting tool 12 at the same time. The rear end of the knife rest base 11 and the front end of the splint 13 offer a positioning groove 14 that matches the U-shaped groove 7 on the cutter body shell 3 and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com