Six-station flexible processing equipment and method for processing work piece

A flexible processing, six-station technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems that cannot guarantee the positioning accuracy and repeat positioning accuracy of the positioning axis, the high cost of the control system, and cannot meet the six-station processing technology Requirements and other issues, to achieve the effect of low manufacturing cost, flexible and accurate control, and occupying a small workshop area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

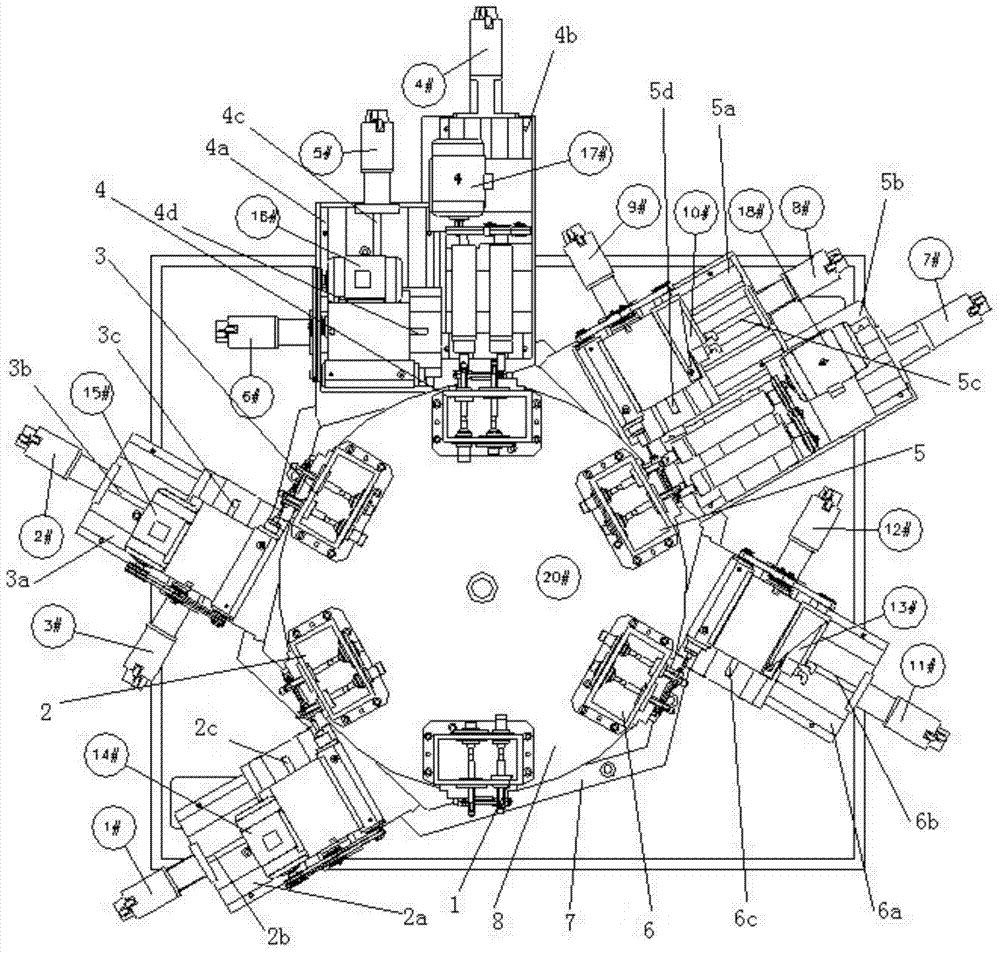

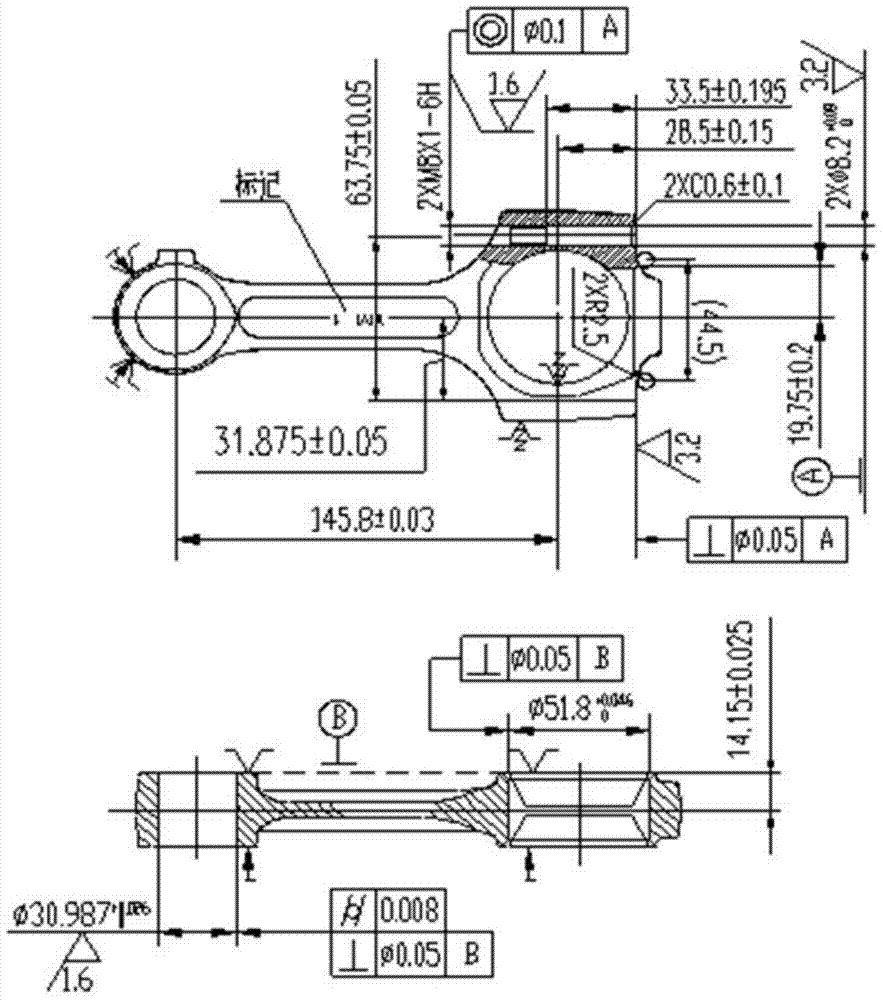

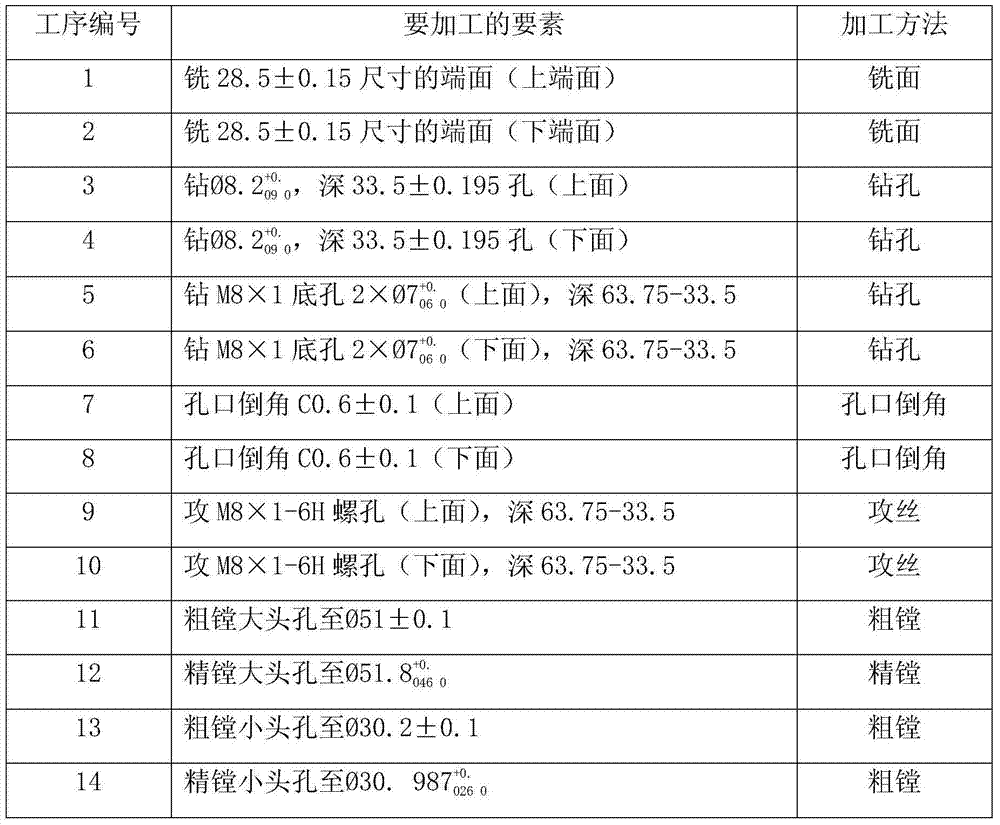

[0026] Such as figure 1As shown, the six-station flexible processing equipment of the present invention includes a turntable seat 7 installed on a fixed base, a rotatable circular turntable 8 installed on the turntable seat, a loading and unloading station 1 and a milling station arranged around the round turntable 2. Drilling station 3, rough boring station 4, fine boring station 5, tapping station 6, loading and unloading station 1 is set on the round turntable 8, milling station 2, drilling station 3, rough Boring station 4, fine boring station 5, and tapping station 6 are all set beside the round turntable. A fixture 1a for clamping workpieces is installed on the loading and unloading station 1 . The milling station 2 is equipped with the first cross slide 2a and the milling device installed on the first cross slide. The X axis of the X-axis slide driven by the first cross slide is driven by the first AC servo motor 1#. The first ball screw 2b, the Y-axis that drives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com