Photo machine pad type platform support structure and manufacturing method thereof

A technology of support structure and photo machine, applied in printing, printing device and other directions, can solve the problems of poor stability of the support structure of the photo machine platform, difficulty in ensuring the machining accuracy of the milling plane, lack of benchmarks for the assembly of the photo machine platform, etc., so as to reduce the processing time of the milling machine. , weight reduction, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

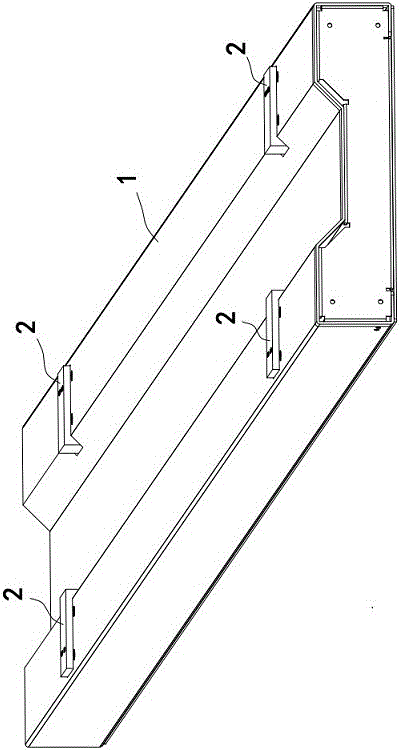

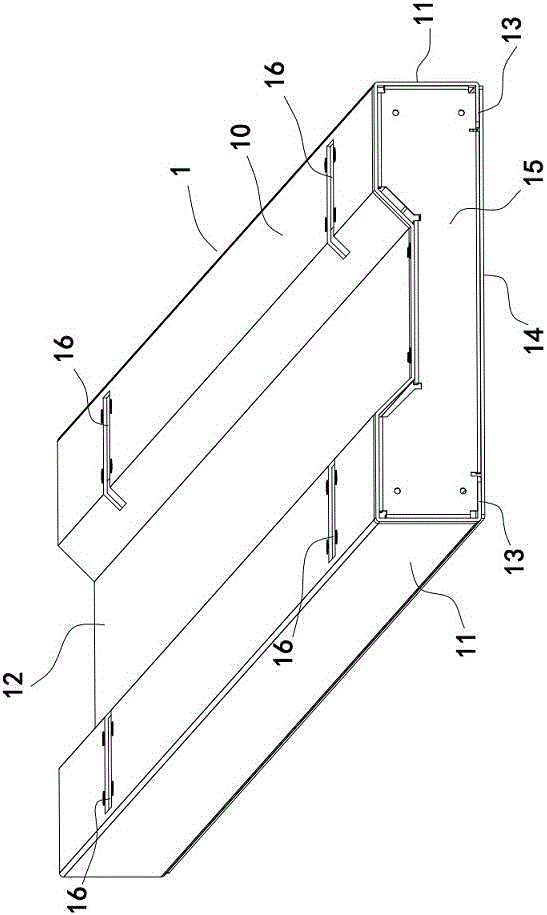

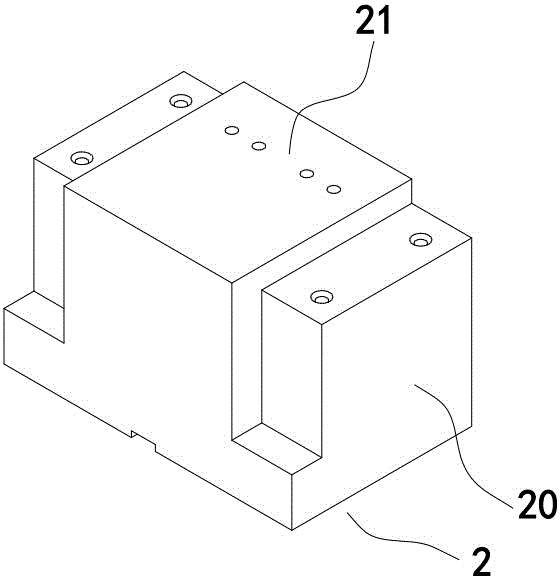

[0016] The pad type platform support structure of the photo machine of the present invention includes a base extending longitudinally, the base is as figure 1 , figure 2 , image 3 , Figure 4 As shown, it is mainly composed of a hollow shell 1 surrounded by thin metal plates and two pairs of pads 2 fixed on the left and right sides of the hollow shell 1 at relative intervals. Among them, the hollow shell 1 is mainly composed of a top plate 10, left and right side plates 11, a bottom plate 14 and end plates 15 at both ends. A trapezoidal groove 12 extending longitudinally is provided at the center of the top plate 1. In this embodiment, the left and right sides Plate 11 is integrally fixed vertically on the left and right sides of top plate 10. At the same time, inverted edges 13 are vertically provided at the bottoms of left and right side plates 11. The boards 15 are respectively fixedly mounted on the front and rear ends of the top board 10 and the bottom board 14 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com