A kind of method adopting water glass and lime emulsion to prepare microporous calcium silicate

A technology of microporous calcium silicate and water glass solution, applied in the direction of silicate, alkaline earth metal silicate, etc., can solve the problems of difficulty in providing products with stable quality, poor product quality stability, complex production process, etc., and achieves remarkable results. Economic and environmental benefits, easy industrialization and promotion, and the effect of simple operation of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First, in the reaction tank, an appropriate amount of milk of lime with a concentration of 85g / L (calculated as CaO) is added, and after the stirring is started, the sodium silicate solution is quickly added, and the concentration of the sodium silicate solution is 25g / L (SiO 2 meter), the modulus is 0.5, and the reaction is carried out by mixing evenly. The reaction conditions are: milk of lime (calculated as CaO) and sodium silicate (SiO 2 The molar ratio of meter) is 0.6:1, the reaction temperature is normal temperature, the reaction time is 20min, and the stirring linear velocity can be 0.9m / s. After the reaction is completed, the obtained product slurry is dehydrated, washed with hot water at 90°C, and dried at 95°C to obtain microporous calcium silicate powder.

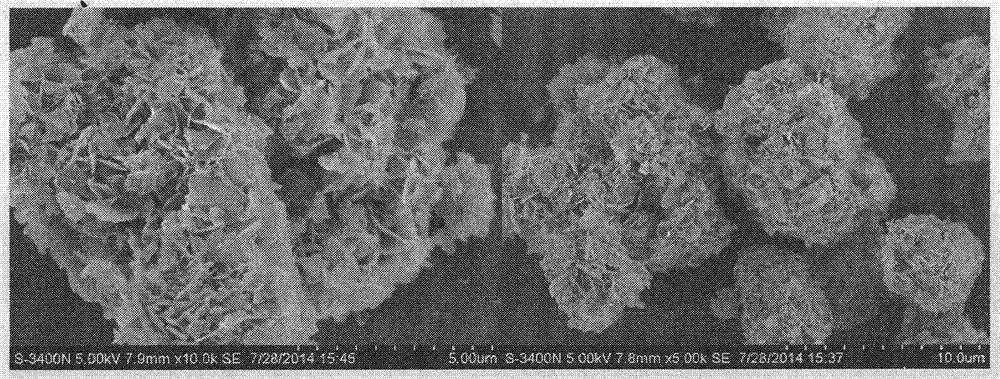

[0029] The microporous calcium silicate powder that present embodiment obtains carries out index test, and the results are shown in Table 1 and figure 1 .

[0030] Table 1. The indicators of the micropo...

Embodiment 2

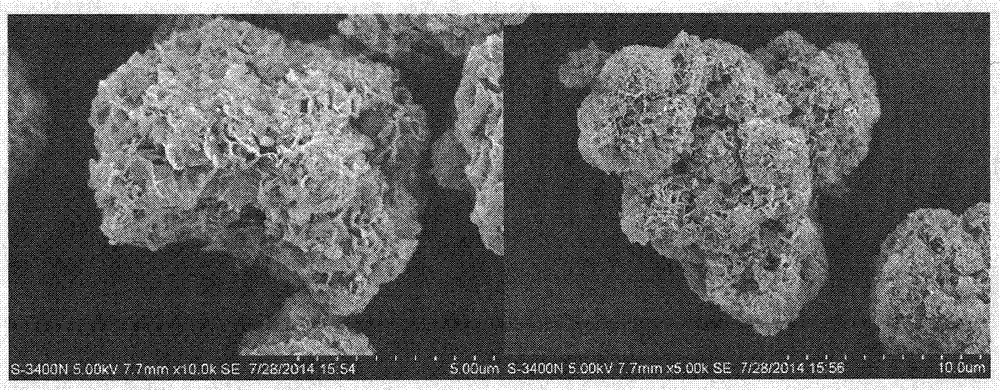

[0033] The microporous calcium silicate powder was prepared by the method in Example 1, except that the modulus of the sodium silicate solution used was 0.8. The microporous calcium silicate powder obtained in this example was tested for indicators, and the results are shown in Table 2. and figure 2 .

[0034] Table 2. The indicators of the porous calcium silicate powder obtained in Example 2

[0035]

Embodiment 3

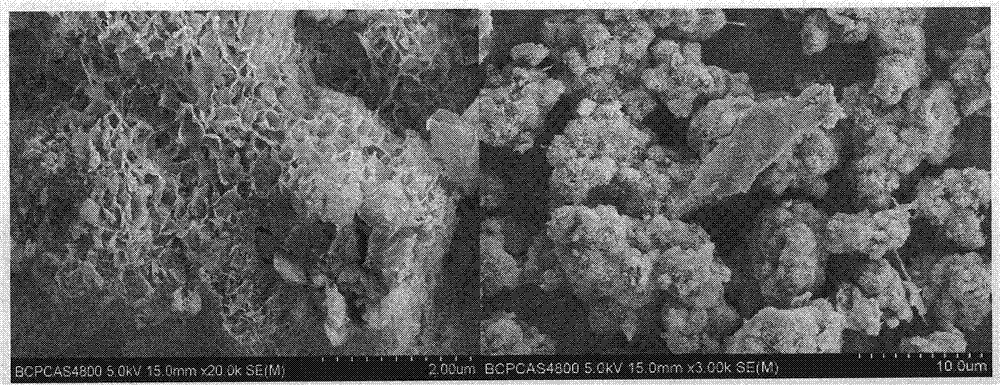

[0037]Microporous calcium silicate powder was prepared by the method in Example 1, except that the molar ratio of milk of lime and sodium silicate was 0.8:1, and the microporous calcium silicate powder obtained in this example was tested for indicators , the results are shown in Table 3 and image 3 .

[0038] Table 3. The indicators of the microporous calcium silicate powder obtained in Example 3

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com