High-strength prestressed anchor bolt

An anchoring bolt and prestressing technology, applied in the direction of bolts, screws, nuts, etc., can solve the problems of high brittleness, poor elasticity and easy loosening of threaded steel bars, and achieve the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

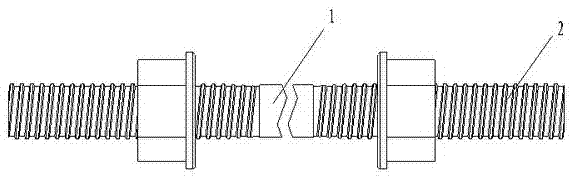

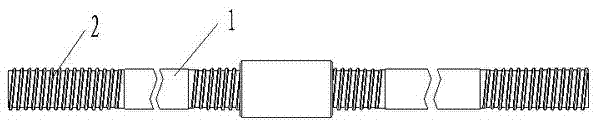

[0024] A high-strength prestressed anchor bolt, including a screw rod 1 and a threaded part 2, figure 1 and 2 They are two common prestressed anchor bolts, figure 1 is to use a hex nut, figure 2 is connected using a connector.

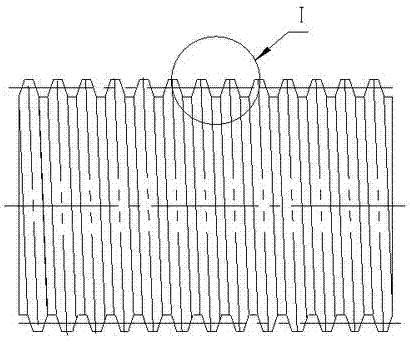

[0025] Bolt is a typical multi-notch part, and its fatigue performance will be obviously affected by various factors such as bolt structure, tooth shape size, material and manufacturing process. According to the unique mechanical factors of bolted joints, the thread groove of bolt It is the concentration point of the stress under the external load of the bolt. The closer the diameter of the thread groove is to the diameter of the round steel during rolling, the greater the bearing capacity, which is also conducive to rolling forming, but the insufficient height of the tooth profile will affect the strength of the tooth profile. Through the calculation of the strength of the tooth type, the strength calculation of the minimum diameter of the bolt, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com