Transmission mechanism for magnetic refrigerator

A technology of transmission mechanism and magnetic refrigerator, which is applied in transmission devices, mechanical energy control, electromechanical devices, etc., can solve the problems of high manufacturing and processing costs, low work efficiency, and high installation accuracy, and achieve low manufacturing costs, good cooling effect, The effect of motion trajectory stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments.

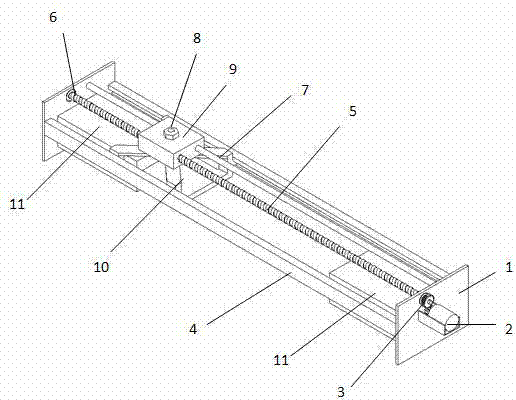

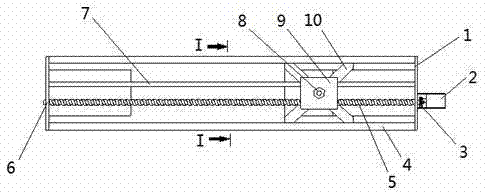

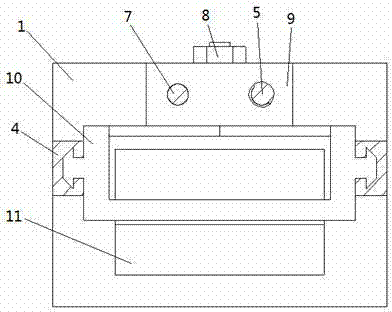

[0033] like Figures 1 to 3 As shown, a transmission mechanism for a magnetic refrigerator includes a screw rod 5 and a slider 9 threadedly engaged with the screw rod 5, the screw rod 5 is rotatably connected and arranged between the bases 1 through a bearing 6, and It includes a claw-shaped packaging box 10, a linear sliding guide rail 4 arranged in parallel between the bases 1, the top of the claw-shaped packaging box 10 is fixedly connected with a slider 9 through a bolt 8, and the two sides of the claw-shaped packaging box 10 Slidingly matched with the linear sliding guide rail 4, a motor 2 is provided on the outside of the base 1 to drive the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com