Integrated caseless ammunition gun system

A caseless, integral technology, applied in the direction of ammunition, cartridge ammunition, weapon accessories, etc., can solve the problems of the G11 system cannot be installed and used, and the manufacturing process of caseless ammunition is complicated, so as to eliminate the danger of spontaneous combustion and achieve high effective quality. , the effect of improving life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

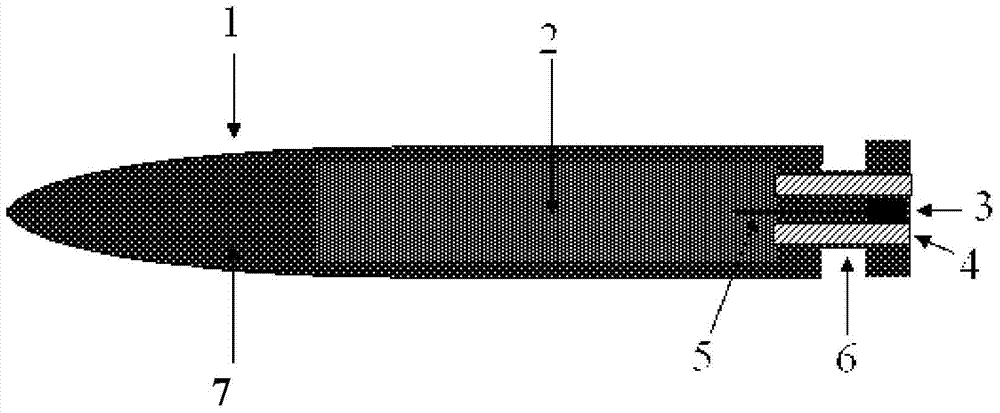

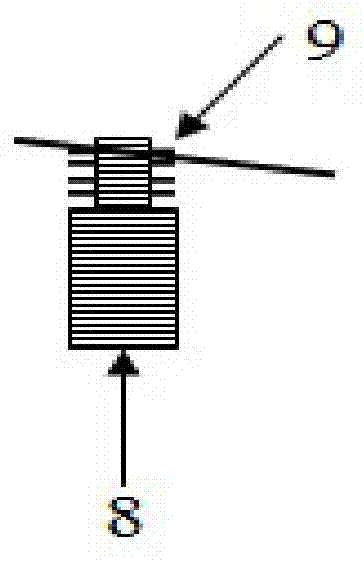

[0026] The integrated caseless bullet gun system of the present invention comprises an integral caseless bullet, a smoothbore gun barrel used in conjunction with the integral type caseless bullet, a positioning slider combination used in conjunction with the integral type Matching bolts.

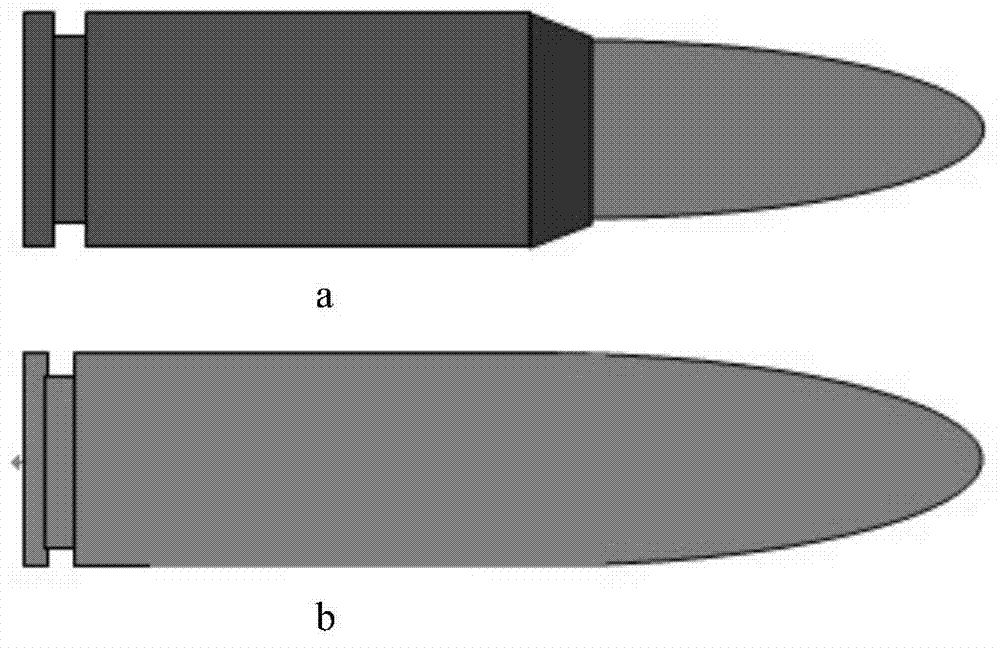

[0027] see figure 1 and figure 2 b, the integral caseless ammunition of the present invention includes an integrated head shell (i.e., a projectile body 1) consistent with the inner diameter of the gun barrel, and the projectile body (1) is provided with a large-scale bullet cone 7 and a propellant column 2, and the head cone 7 and the propellant column 2 are arranged sequentially from the head of the missile body 1 to the tail; Each is provided with a flame port 4, and the flame port position is symmetrical, deviates from the axis of the projectile body 1 with the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com