Mounting device for large mass test piece on vibrating centrifuge

A vibrating centrifuge and installation device technology, applied in the direction of centrifuges, etc., can solve the problems of reducing the bearing capacity, the deviation between the working state and the ideal state, and the limitation of the effective mass of the test piece, so as to improve the load capacity and the overall test capacity. Enhance and improve the force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

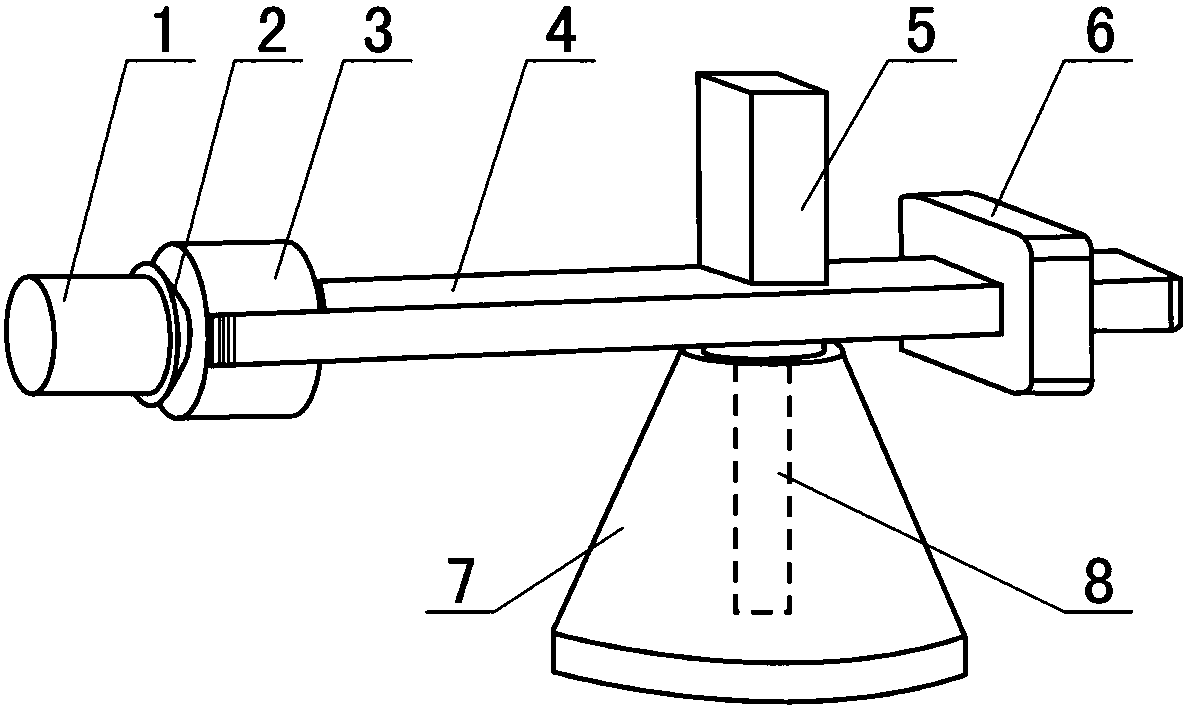

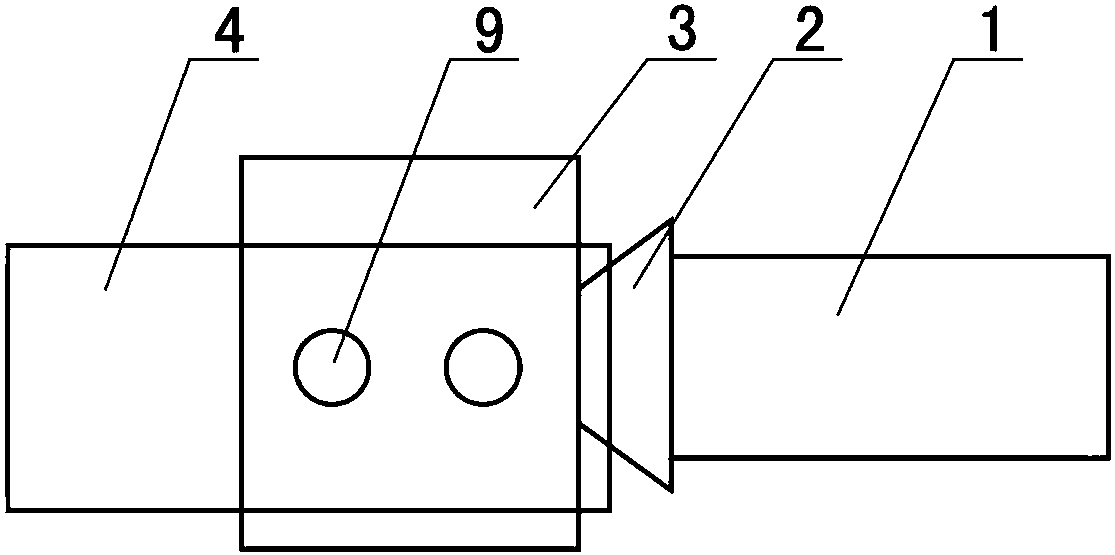

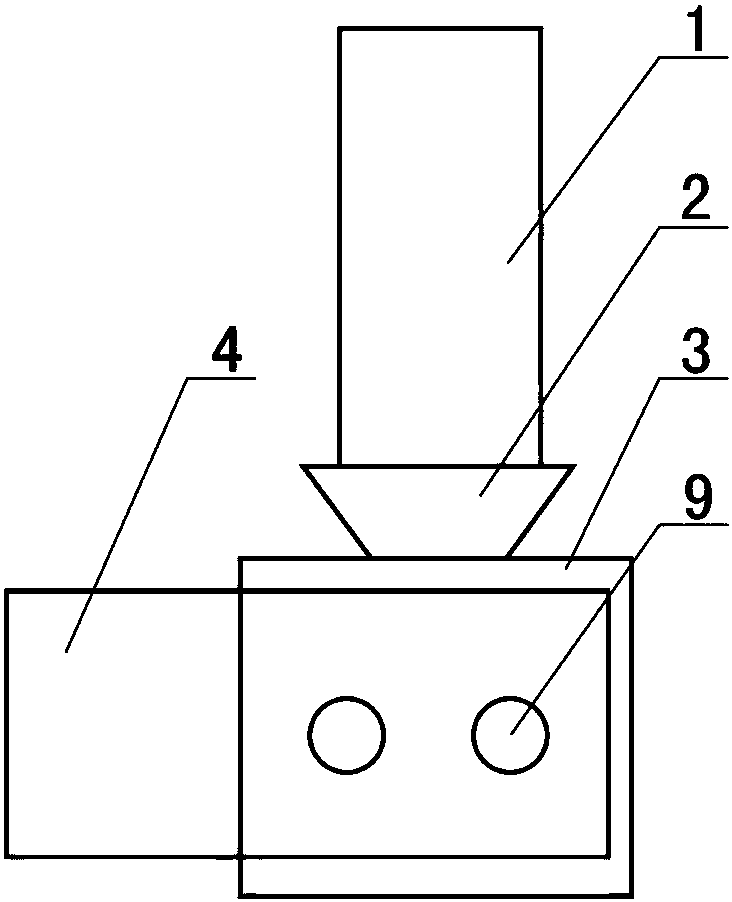

[0023] Such as figure 1 , Figure 5 and Figure 6 As shown, an electric vibrating table 3 is installed on the rotating arm 4 of the vibrating centrifuge of the present invention, and one end of the test piece 1 is installed on the table top 2 of the electric vibrating table 3, and the large mass test piece on the vibrating centrifuge of the present invention The installation device includes an auxiliary extension table 15, a hydrostatic bearing 14 and a clamp 13, and the auxiliary extension table 15 is installed on the rotating arm 4. If the electrodynamic vibrating table 3 is installed along the arm, then as Figure 5 As shown, one end of the auxiliary extension table 15 is installed under the rotating arm 4, the top of the other end of the auxiliary extension table 15 and the bottom of the test piece 1 are close to each other and there is a gap, and the hydrostatic bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com