Oblique incidence high-reflection film laser electric field distribution design method

A high-reflection film and design method technology, applied in optics, optical components, instruments, etc., can solve problems such as inability to optimize electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

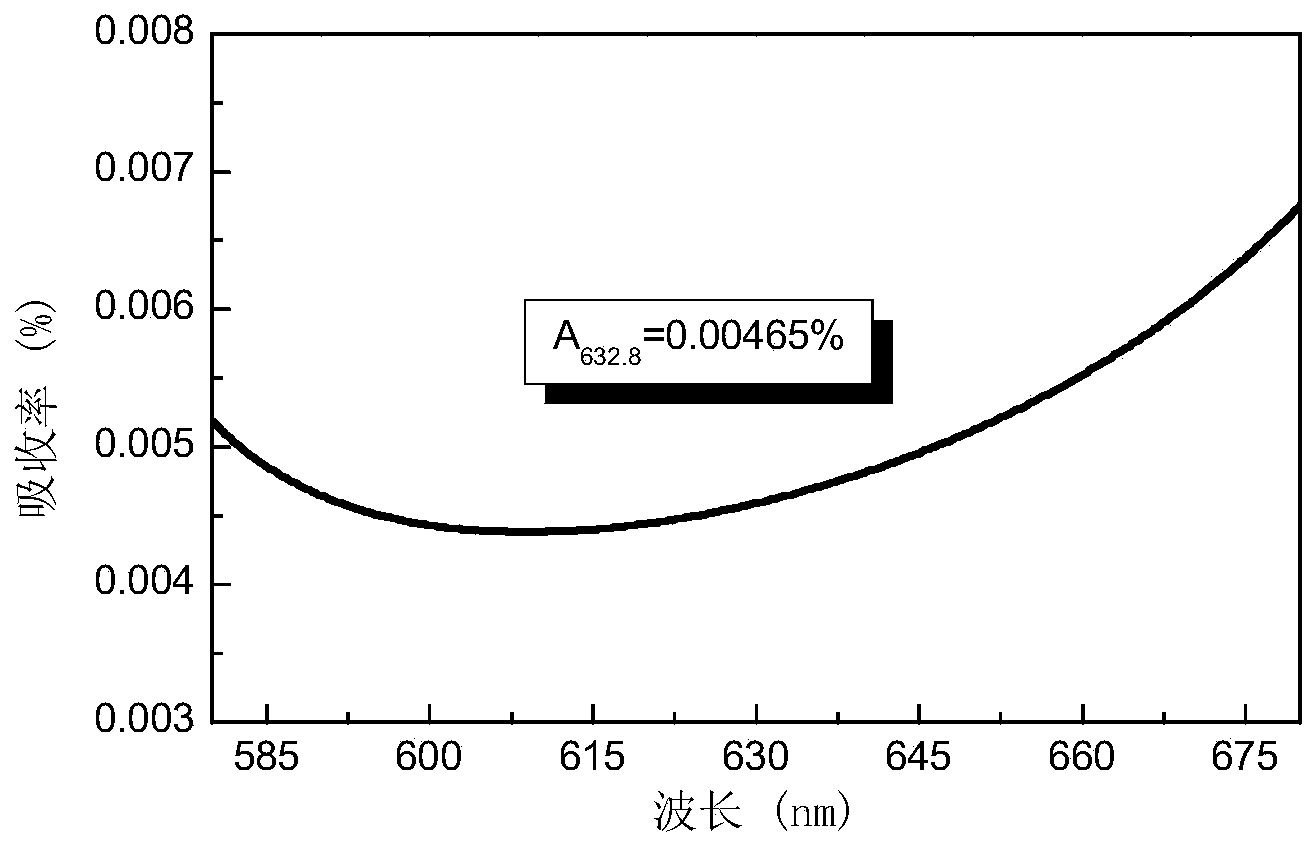

[0044] The basic structure of the film is as described above. The following is an example design for a 632.8nm laser film, the incident angle is 45°, and the polarization state is S polarization:

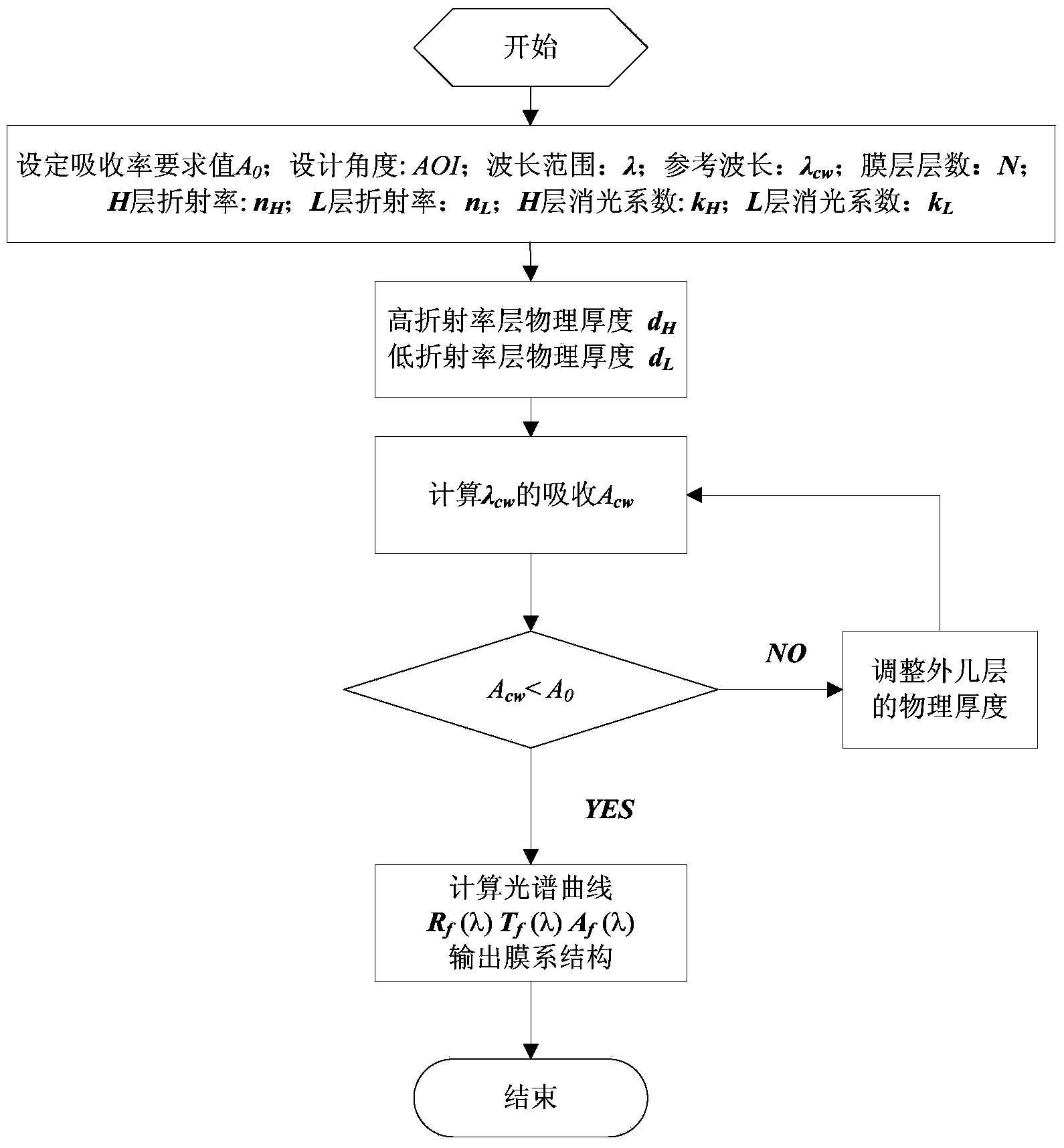

[0045] 1. High-reflection film structure design steps:

[0046] 1) Set the wavelength of the laser to 632.8nm, the working angle to 45°, and the high refractive index material to be Ta 2 o 5 , the low refractive index material is SiO 2 ; The refractive indices of high refractive index and low refractive index film materials are respectively n H = 2.10 and n L =1.47; the extinction coefficients of high refractive index and low refractive index film materials are k respectively H =2×10 -5 and k L =1×10 -6 ;

[0047] 2) The calculated optical thickness coefficients of the high refractive index and low refractive index films are α=1.0620 and β=1.1406, respectively;

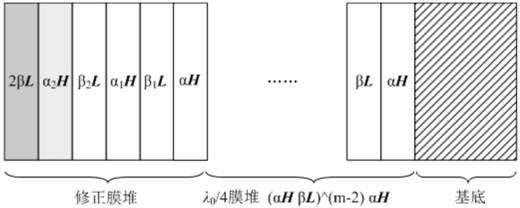

[0048] 3) Set the basic period of the film as m=17; then the corrected film structure is: substrate / (1.062H 1.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com