Mountain pasture conditioning machine

A pasture and mountain technology, applied in the structural field of mountain pasture conditioning machines, can solve the problems of difficult large-scale promotion and application, low quality of grass products, high labor intensity, etc., to achieve flexible operation, strong ability to adapt to terrain, and good terrain imitation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

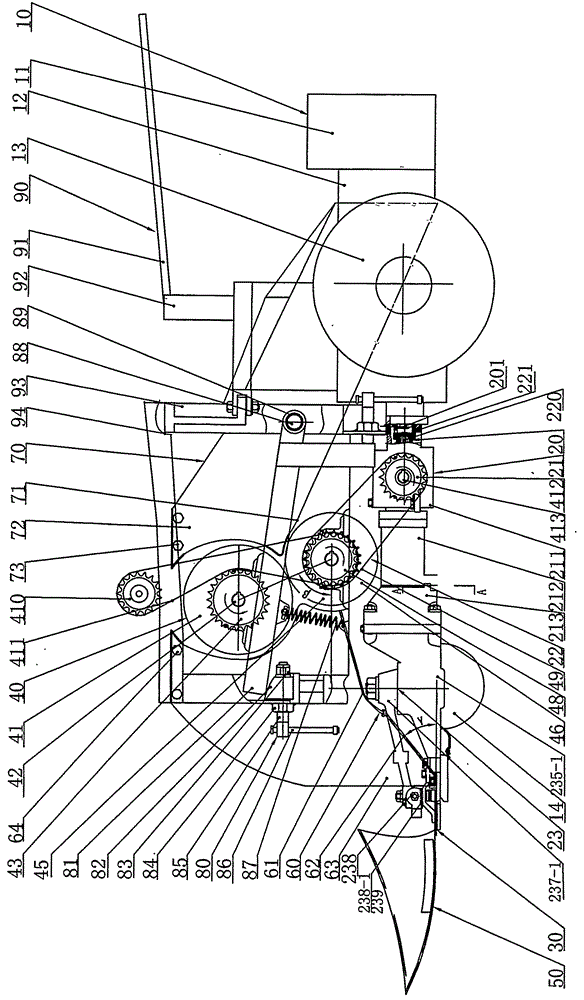

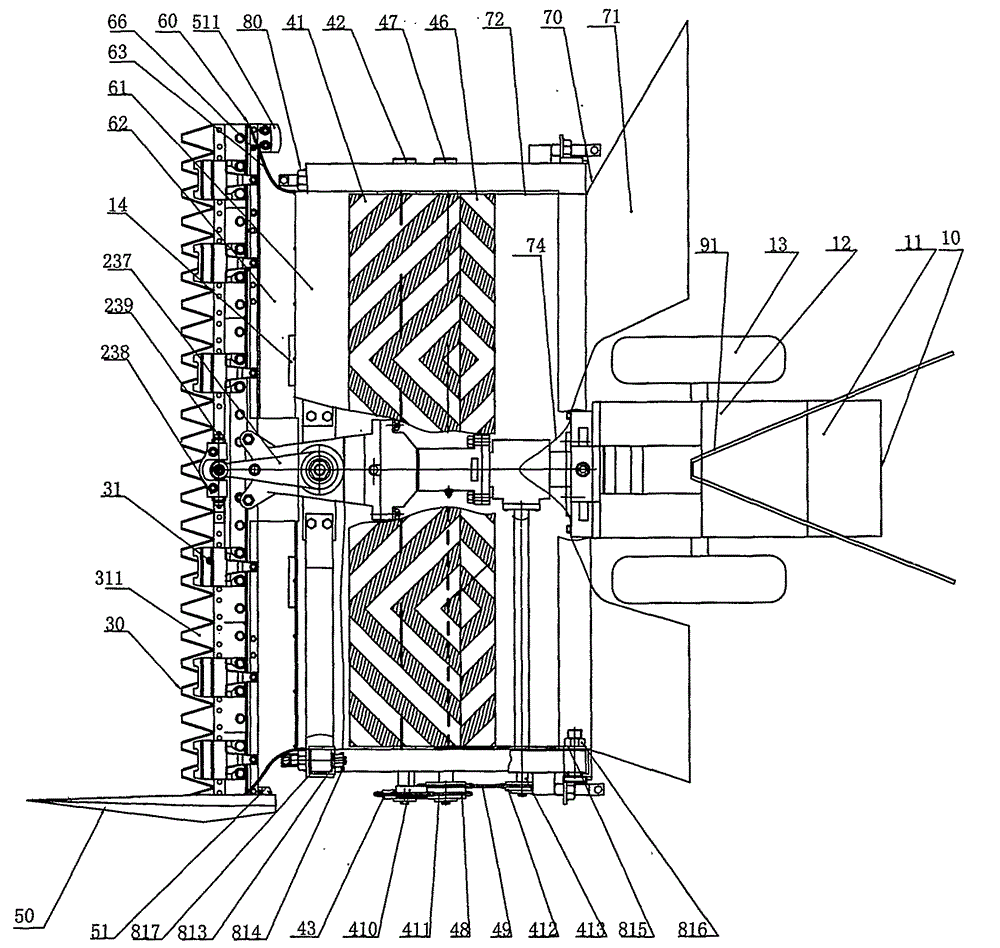

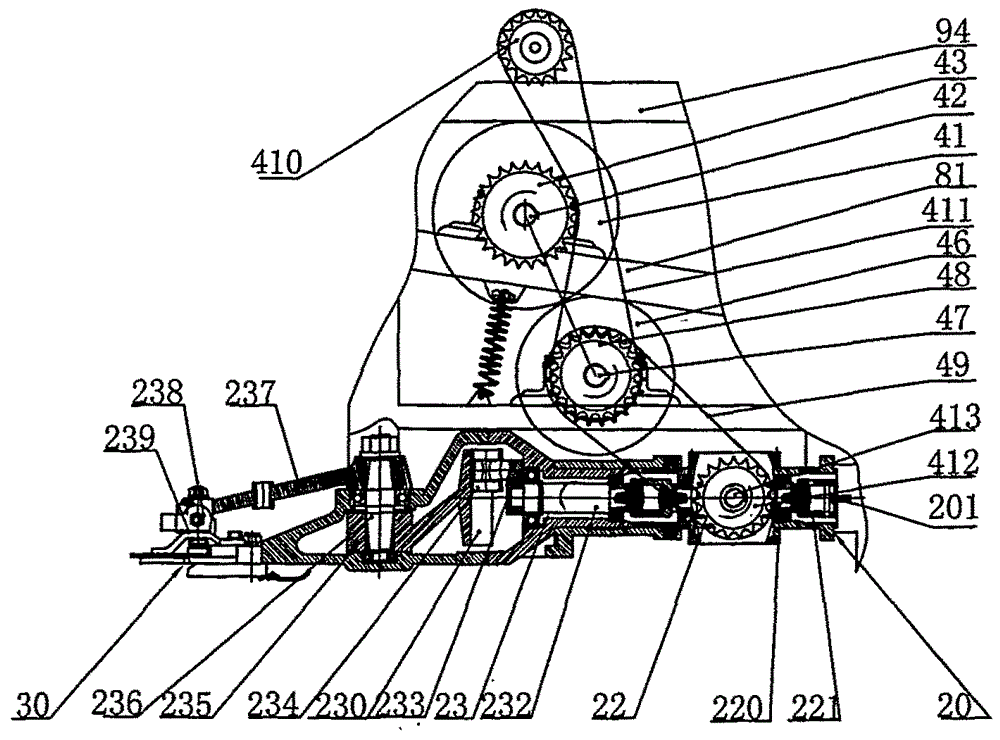

[0027] Example 1, see Figure 1-5(c) , the mountain pasture conditioning machine includes a power assembly 10 made up of a power machine 11, a reducer 12, a walking ground wheel 13, and a support wheel 14. A transmission system 20 and a housing assembly are arranged in front of the power output shaft 201 of the reducer 12. 21. Cutting system 30, flattening system 40, crop divider 50, profiling device 51, grass guiding device 60, grass collecting and laying device 70, flattening gap adjusting device 80 and frame assembly 90. The transmission system 20 includes a power output shaft 201 , a coupling 221 , a transmission main shaft 220 , a cutting transmission system 23 and a flattening transmission system 22 . The transmission main shaft 220 passes through the shaft coupling 221, the cutting transmission shaft 232, the eccentric wheel 233, and the semicircular arc chute 230. A cylindrical slide block 234, a connecting rod 235, a spline shaft 236, a rocker shaft 234, and a connect...

Embodiment 2

[0035] Example 2 is the same as Example 1, but the difference is that the described implementation operation site belongs to arid, terraced loess soil, Longdong alfalfa grown for 3 years, fresh grass harvested at the early flowering stage, with an average of 330 plants per square meter, and an average plant height of 550 mm, the upper pressure roller 41 and the lower pressure roller 46 are intermeshed herringbone rubber rollers, the angle β between the vertical line between the upper pressure roller shaft 42 and the lower pressure roller shaft 47 of the herringbone rubber roller and the horizontal plane is 65°.

[0036] The flattening gap adjusting device 80 includes a limit slider 82 with an arc surface with a radius of 50mm on the upper surface; the upper pressing roller 41 and the lower pressing roller 46 control the flattening gap by rotating the adjustment screw 85 times 2mm;

[0037] The grass guide device 60 includes an angle γ between the floating grass guide plate 62...

Embodiment 3

[0040] Example 3 is the same as Example 1, but the difference is that the place where the operation is carried out belongs to irrigated land, intercropping field sandy loam soil, Gannong No. 3 alfalfa that has grown for 3 years, and the first harvest of fresh grass in the early flowering stage. 380 plants per square meter, with an average plant height of 750 mm. The upper pressure roller 41 and the lower pressure roller 46 are intermeshed herringbone rubber rollers, and the vertical connection between the herringbone rubber upper pressure roller shaft 42 and the lower pressure roller shaft 47 The angle β between the line and the horizontal plane is 80°.

[0041] The flattening gap adjustment device 80 includes a limit slider 82 with an arc surface with a radius of 30 mm on the upper surface; the upper pressing roller 41 and the lower pressing roller 46 control the flattening gap by rotating the adjustment screw 85 times 3mm;

[0042] The grass guide device 60 includes an angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com