High-temperature disinfection cabinet

A disinfection cabinet, high temperature technology, applied in the field of kitchen utensils, can solve the problems of high price, affect the use effect, high requirements for thermal insulation materials, etc., and achieve the effects of not easy to accidentally touch, fast heating speed, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the present invention is further described:

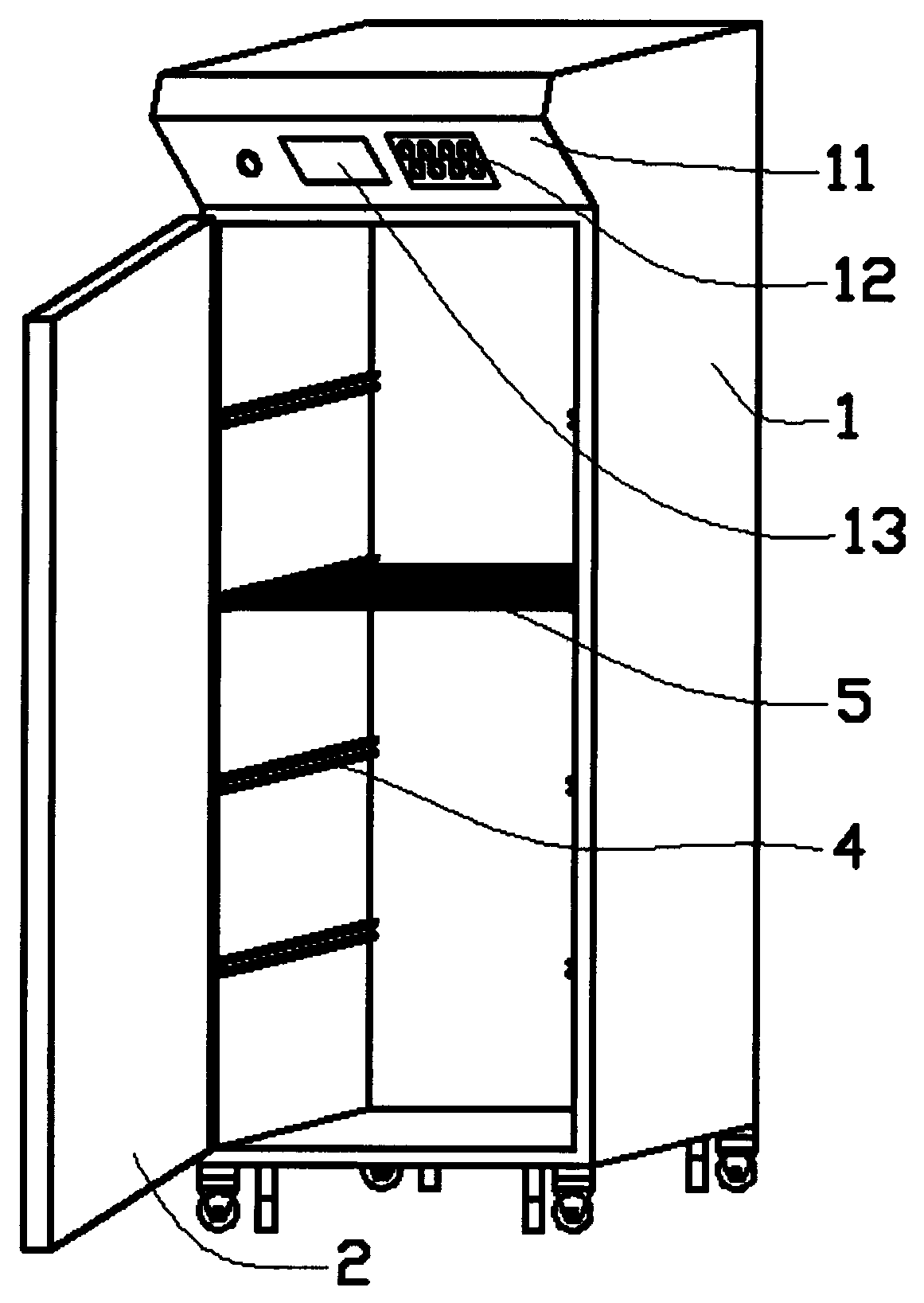

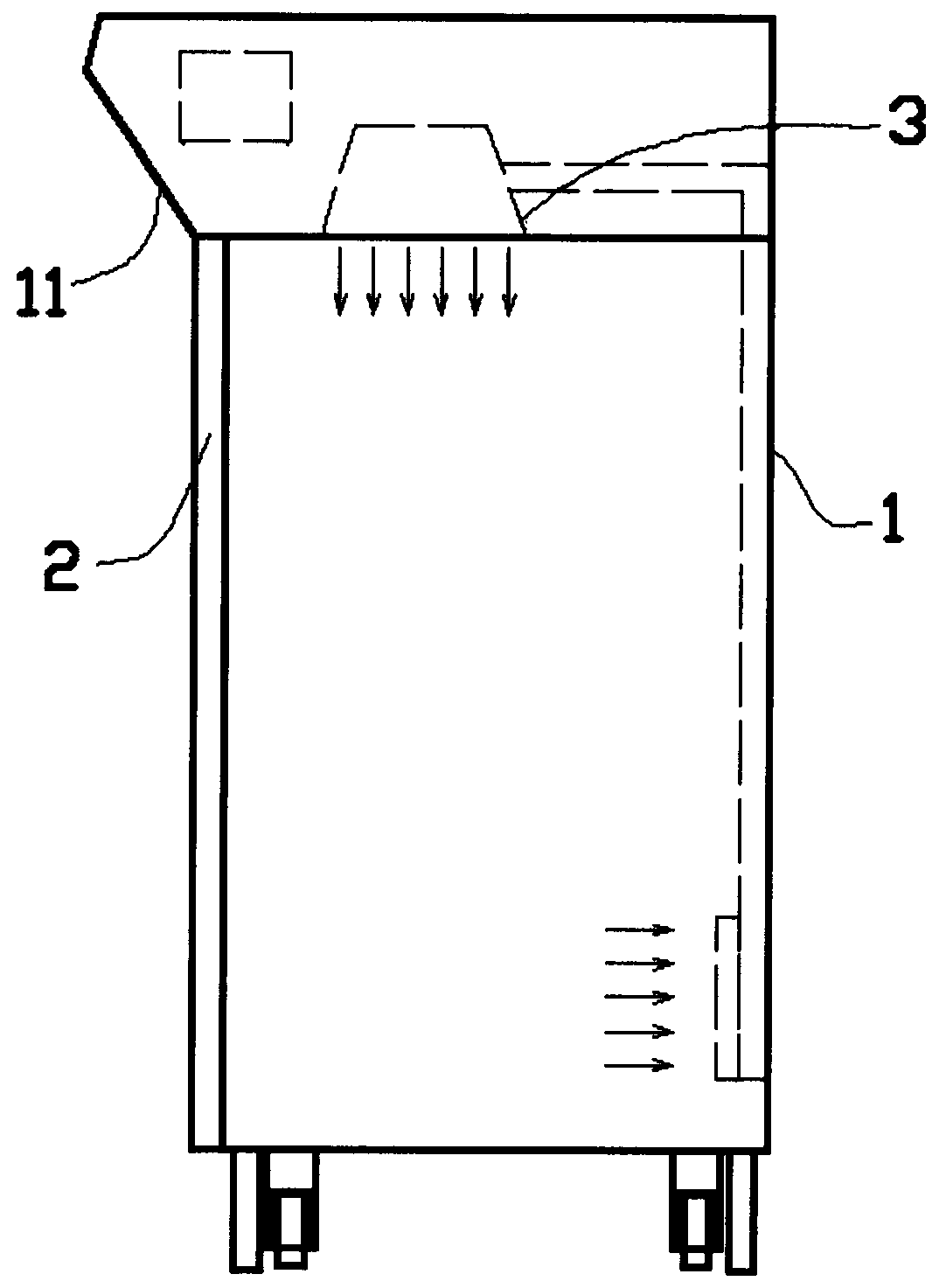

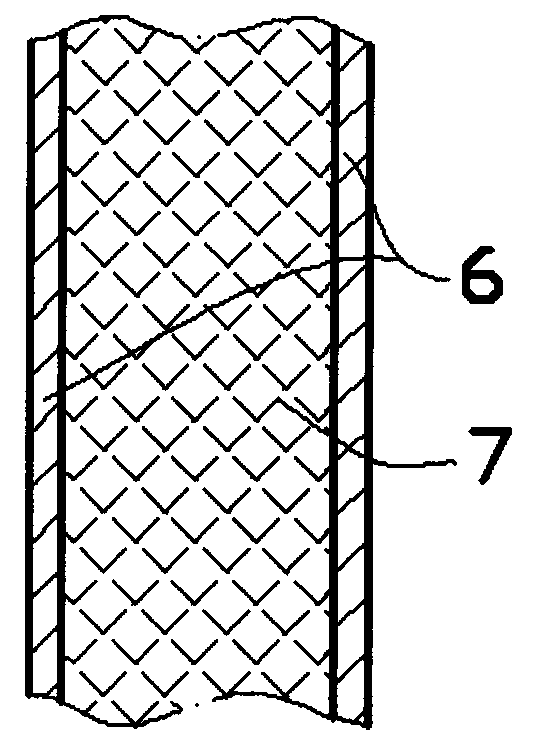

[0016] Such as figure 1 As shown in the embodiment, the high-temperature disinfection cabinet includes a cabinet body 1 and a thermal insulation door 2; the thermal insulation door 2 is installed on the front side of the cabinet body 1, and the cabinet body 1 is in the shape of a vertically placed cuboid; The four corners of the lower part are evenly distributed with universal rollers, which can facilitate the movement of the high-temperature disinfection cabinet. At the same time, there is also a height-adjustable leg next to the universal roller, so that the leg can be raised when the high-temperature disinfection cabinet is not required to move, and the universal roller is overhead, so that the high-temperature disinfection cabinet can be fixed. not moving. The upper part of the front side insulation door 2 of the cabinet body 1 is designed with an extending end, and the lower part o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com