Intelligent multi-station cylinder sleeve centrifugal casting machine

A technology of centrifugal casting machine and cylinder liner, which is applied in the field of mechanical casting, can solve the problems that the process cannot be well controlled, the product quality is difficult to be controlled, and the overall production efficiency is low, so as to reduce labor costs, high degree of automation, and production efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

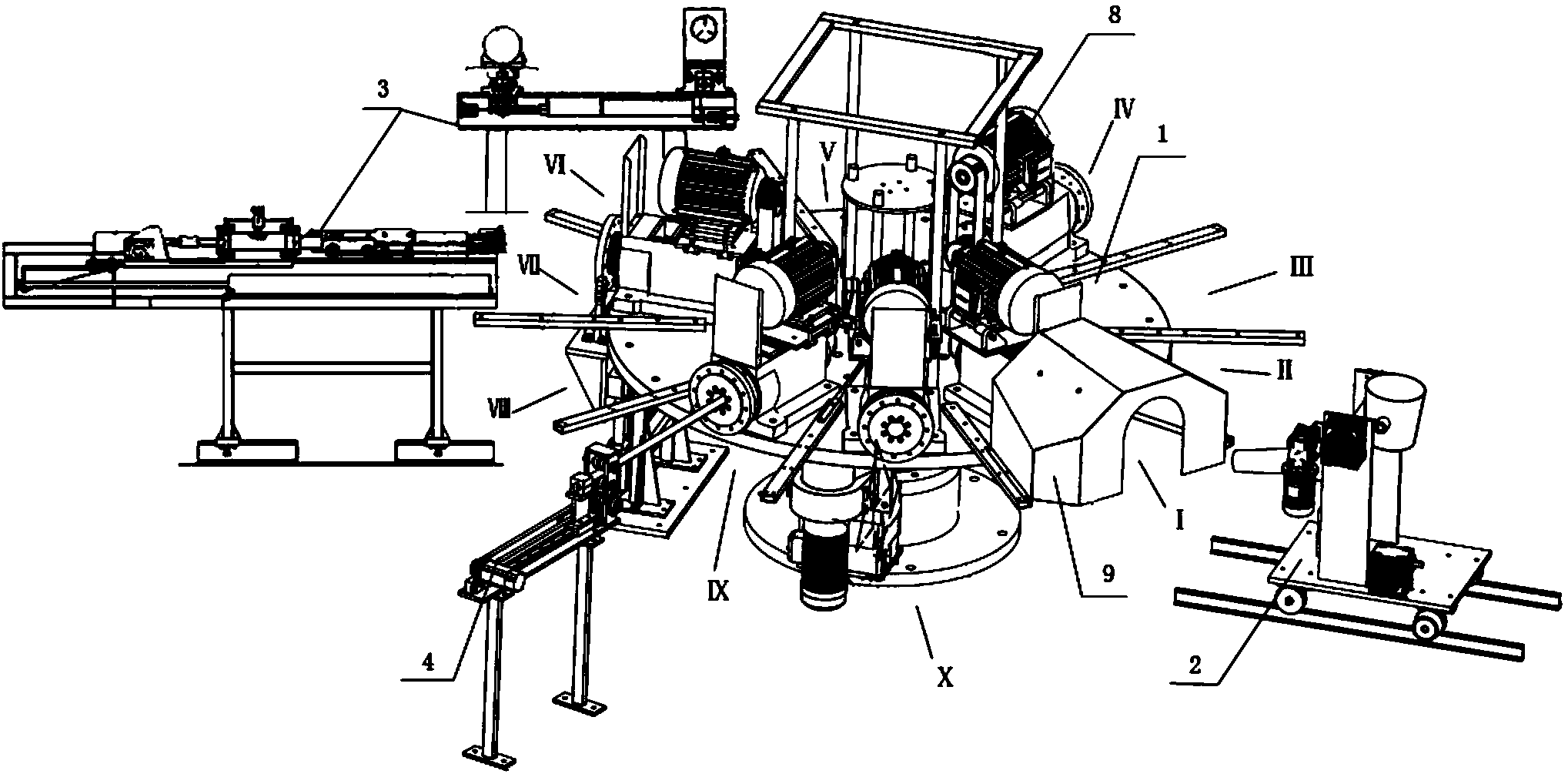

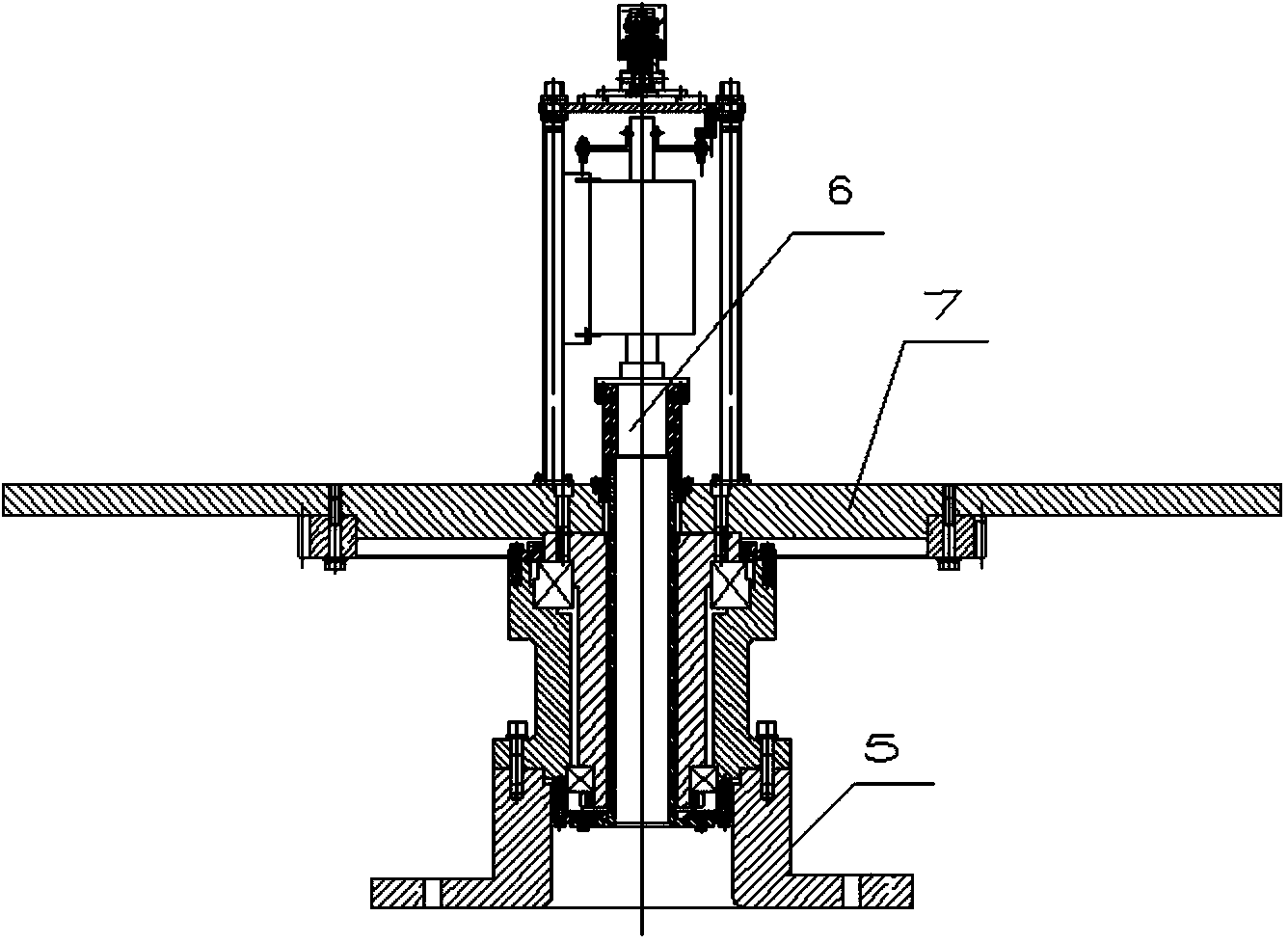

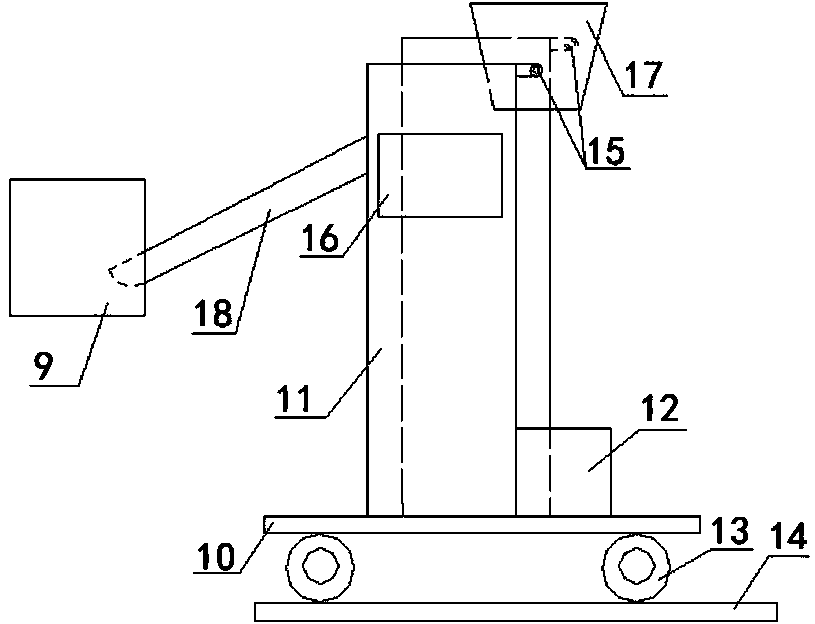

[0029] Such as Figure 1 ~ Figure 2 An intelligent multi-station cylinder liner centrifugal casting machine shown includes a turntable mechanism 1, a casting mechanism 2, an automatic liner fetching mechanism 3, and an automatic paint spraying mechanism 4; the turntable mechanism 1 consists of a base 5, a main shaft 6, and a turntable 7 Composition, the lower end of the main shaft 6 is connected with the base 5, the main shaft 6 runs through the center of the turntable 7, the turntable 7 is fixedly connected with the main shaft 6, and the turntable 7 is divided into casting station I, cooling station aII, cooling station bIII, cooling station cIV, Aging station Ⅴ, door panel removal station Ⅵ, material removal station Ⅶ, cleaning station Ⅷ, coating station Ⅸ, drying station Ⅹ, a total of ten stations, ten stations are respectively connected with motor 8, casting station I is connected with a mold 9; the casting mechanism 2, the automatic cylinder liner fetching mechanism 3, an...

Embodiment 2

[0038] The structure and connection mode of each part of the multi-station cylinder liner centrifugal casting machine adopted in embodiment 2 are the same as those in embodiment 1, and the different technical parameters are as follows:

[0039] 1. The shape of the seat support 32 is U-shaped;

[0040] 2. The power of the travel reduction motor 12 is 0.35kW;

[0041] 3. The power of the ladle deceleration motor 16 is 0.35kW;

[0042] 4. The moving speed of the roller 13 is 3.5m / min;

[0043] 5. The moving speed of the slider 39 is 1m / min;

[0044] 6. The working temperature automatically sensed by the temperature sensor 42 is 300°C;

[0045] 7. The number of times the slide block 39 reciprocates and repeats the spraying action is 4 times.

Embodiment 3

[0047] The structure and connection mode of each part of the multi-station cylinder liner centrifugal casting machine adopted in embodiment 3 are the same as those in embodiment 1, and the different technical parameters are as follows:

[0048] 1. The power of the travel reduction motor 12 is 0.4kW;

[0049] 2. The power of the ladle deceleration motor 16 is 0.4kW;

[0050] 3. The moving speed of the roller 13 is 4.0m / min;

[0051] 4. The moving speed of slider 39 is 1.5m / min;

[0052] 5. The working temperature automatically sensed by the temperature sensor 42 is 450°C;

[0053] 6. The sliding block 39 reciprocates and repeats the spraying action for 5 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com