Automatic variable-pitch mechanism for center distance of double-shaft tightening machine

A technology of variable distance mechanism and tightening machine, which is applied in metal processing, metal processing equipment, manufacturing tools, etc. It can solve the problem that the center of the distribution circle cannot coincide with the center of the bolt distribution circle, the adjustment of the position of the tightening shaft is cumbersome and inaccurate, and the center of the tightening shaft The position is not accurate enough to achieve the effect of high production efficiency and automation, simple structure and good self-locking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

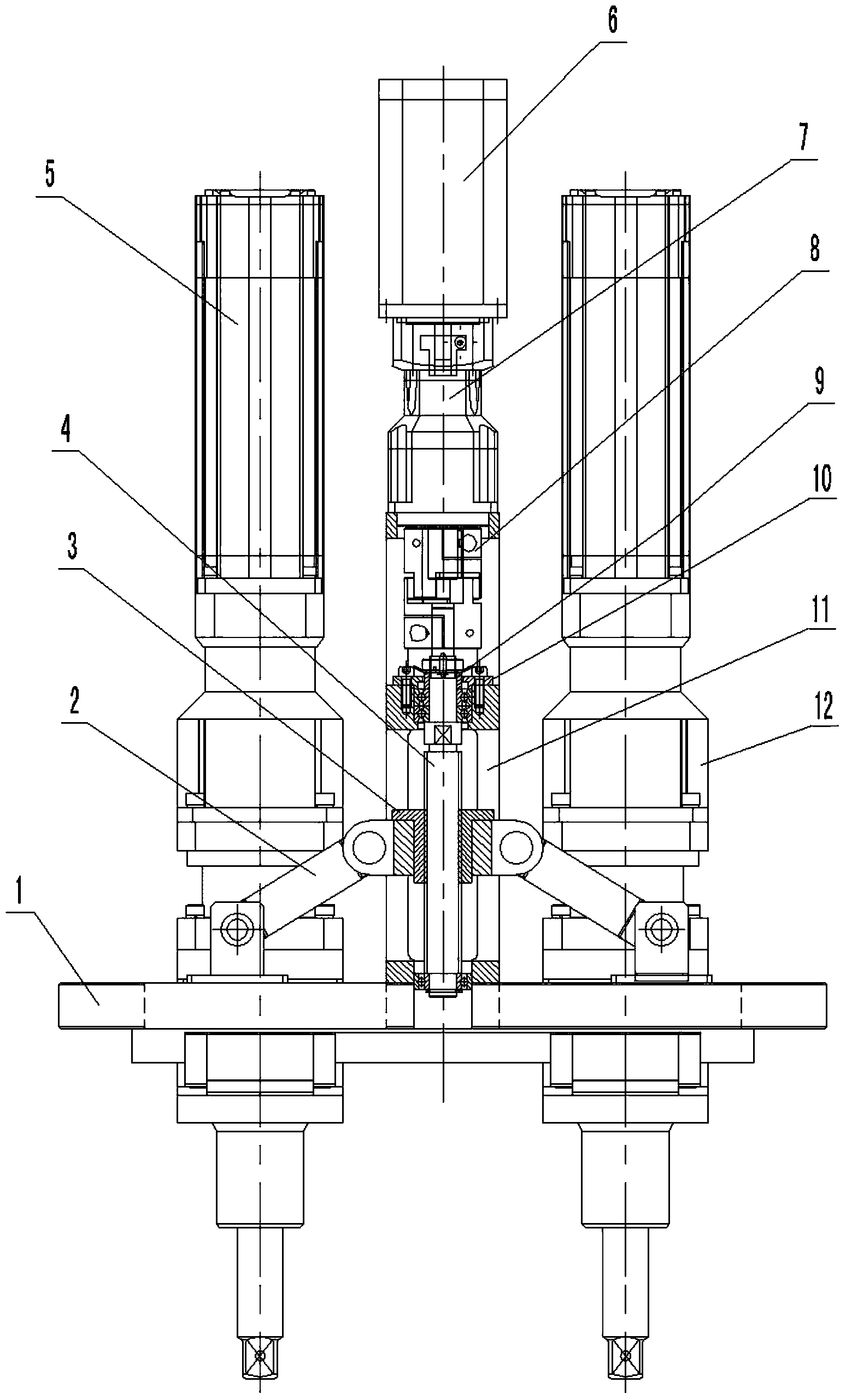

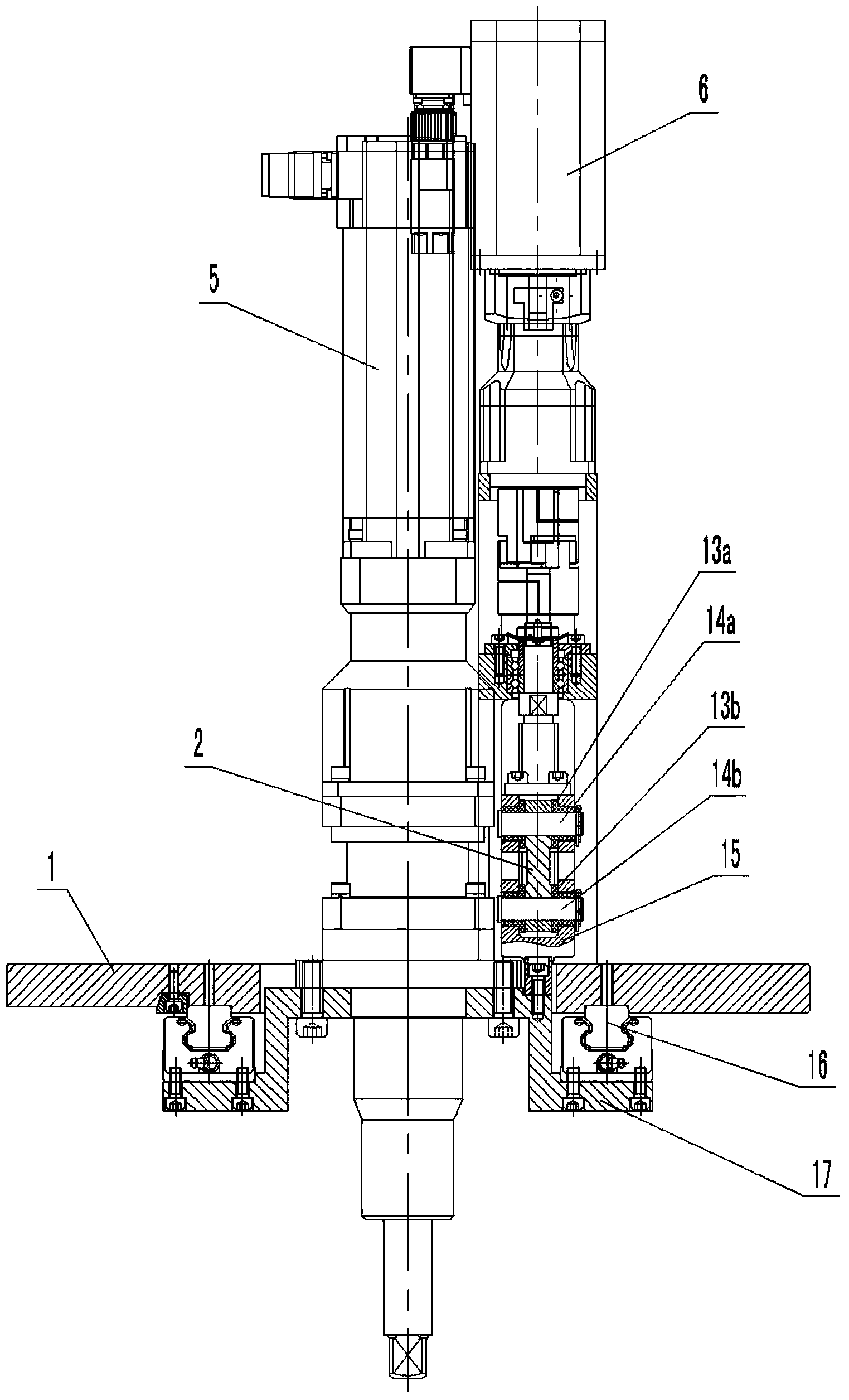

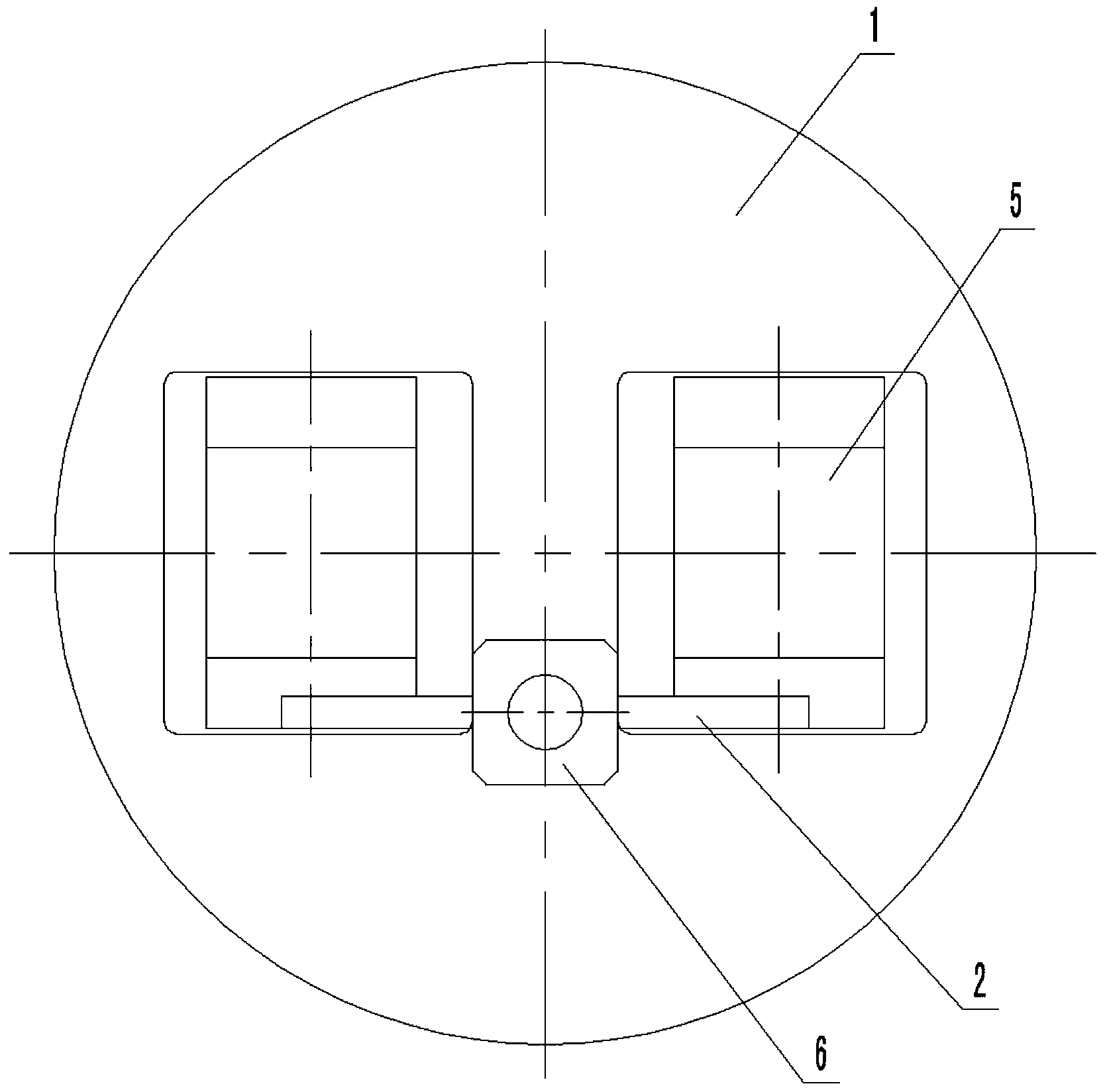

[0020] see figure 1 , figure 2 and image 3 , the structure of the center distance automatic variable distance mechanism of the biaxial tightening machine in this embodiment is set as:

[0021] Two sets of vertical tightening shafts 5 are arranged on the variable-pitch mounting plate 1 fixed horizontally. The diameters of the two sets of tightening shafts 5 are on the same straight line A. The shaft bracket 17 is installed on the pitch-variable mounting plate 1, and the two sets of tightening shafts 5 can move toward each other along the straight line A on the pitch-variable mounting plate 1 driven by the respective tightening shaft brackets 17;

[0022] The screw nut pair is set, the screw mandrel 4 in the screw mandrel nut pair is vertically arranged, the orthographic projection of the screw mandrel 4 and the two sets of tightening shafts 5 on the pitch-variable mounting plate 1 is in the position of an isosceles triangle, and The orthographic projection of the screw 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com