Sectional machining structure of large stamping die set

A segmented, die set technology, applied in the direction of forming tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inability to process, there are hidden dangers in handling safety, and difficult processing, so as to meet the requirements of ensuring processing accuracy and improve Processing safety and the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

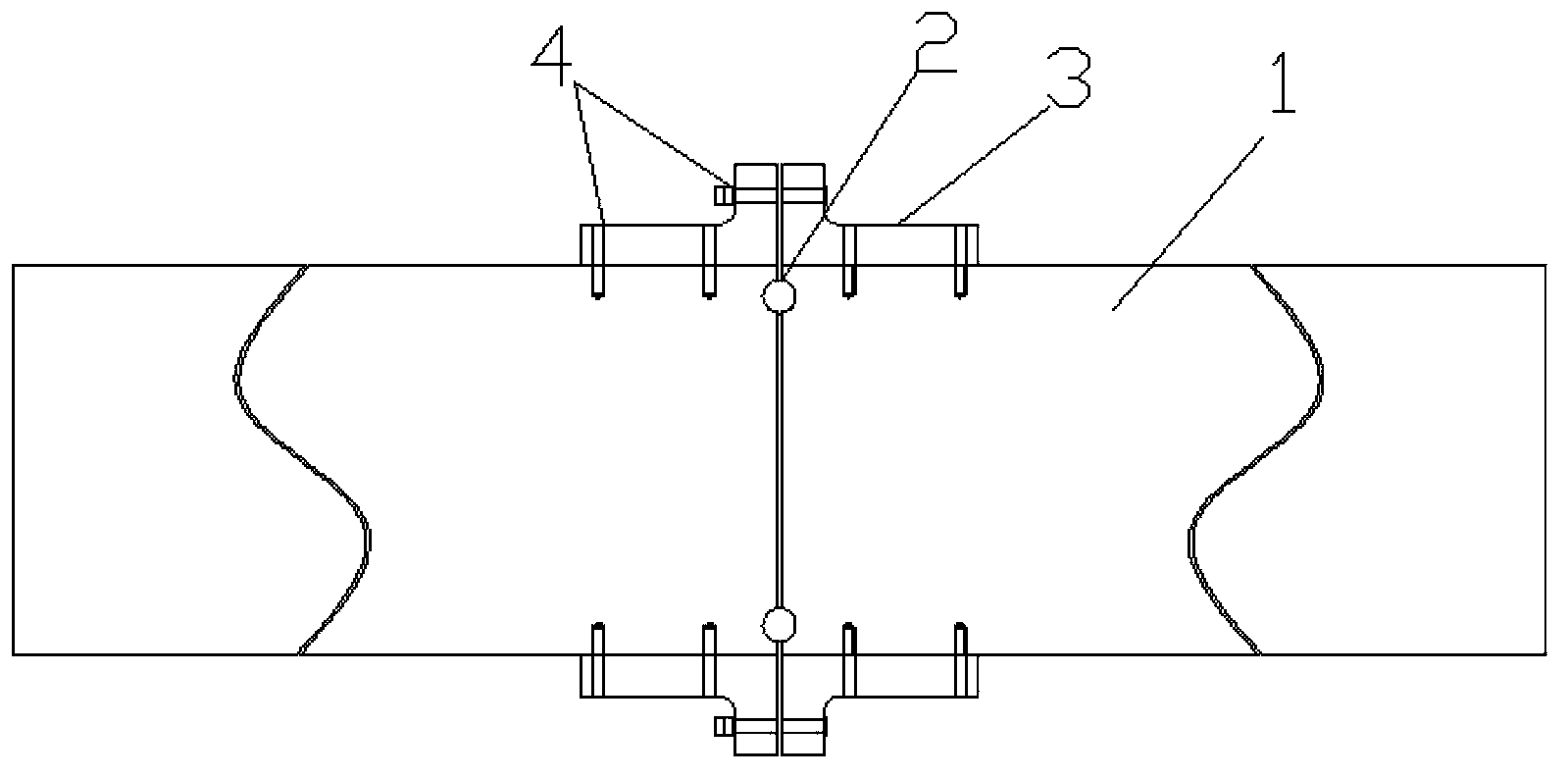

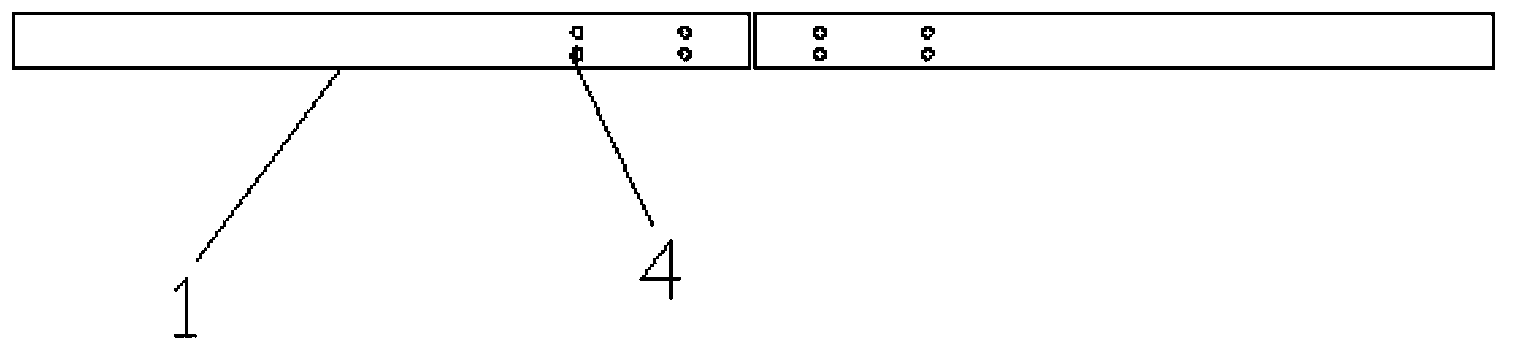

[0014] Such as figure 1 and figure 2 As shown, a segmented processing structure of a large-scale stamping die frame is characterized in that it includes several sub-templates 1 for processing a large-scale stamping die frame, and two adjacent sub-templates are detachably and fixedly connected to form a mother template. At least one common positioning datum 2 is arranged at intervals on the opposite end faces of adjacent two sub-templates when they are connected. In this way, several sub-templates are fixedly connected to form a master template, and at least one common positioning reference can ensure the hole position accuracy of the guide on the template after connection. By designing templates assembled in separate parts, it can effectively reduce processing costs, reduce processing difficulty, improve processing safety, and facilitate handling while ensuring processing accuracy requirements. It can be applied to general processing centers and is not limited to super-large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com