Fixed magnesite roof panel production equipment

A kind of production equipment and fixed technology, applied in the direction of layered products, lamination devices, lamination auxiliary operations, etc., can solve the problems of low efficiency, heavy labor, etc., achieve convenient operation, realize automatic mechanization, and meet the requirements of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

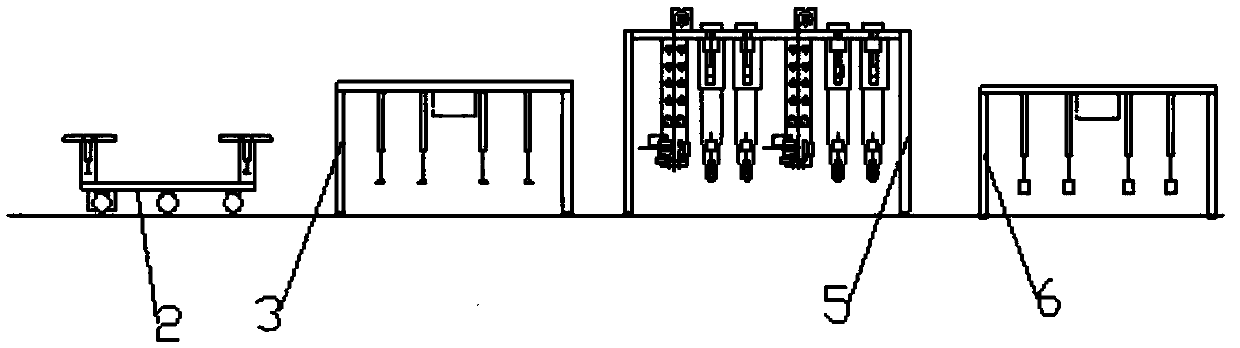

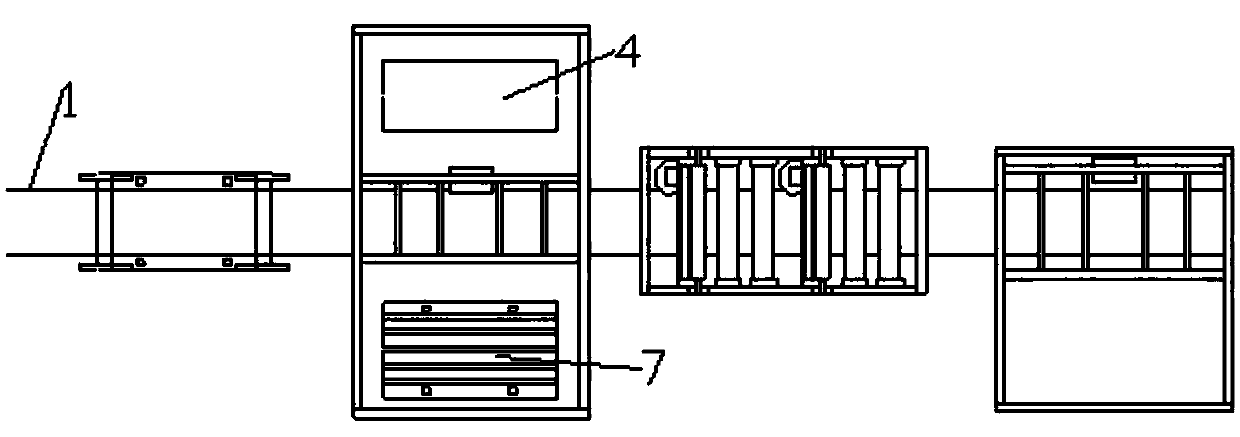

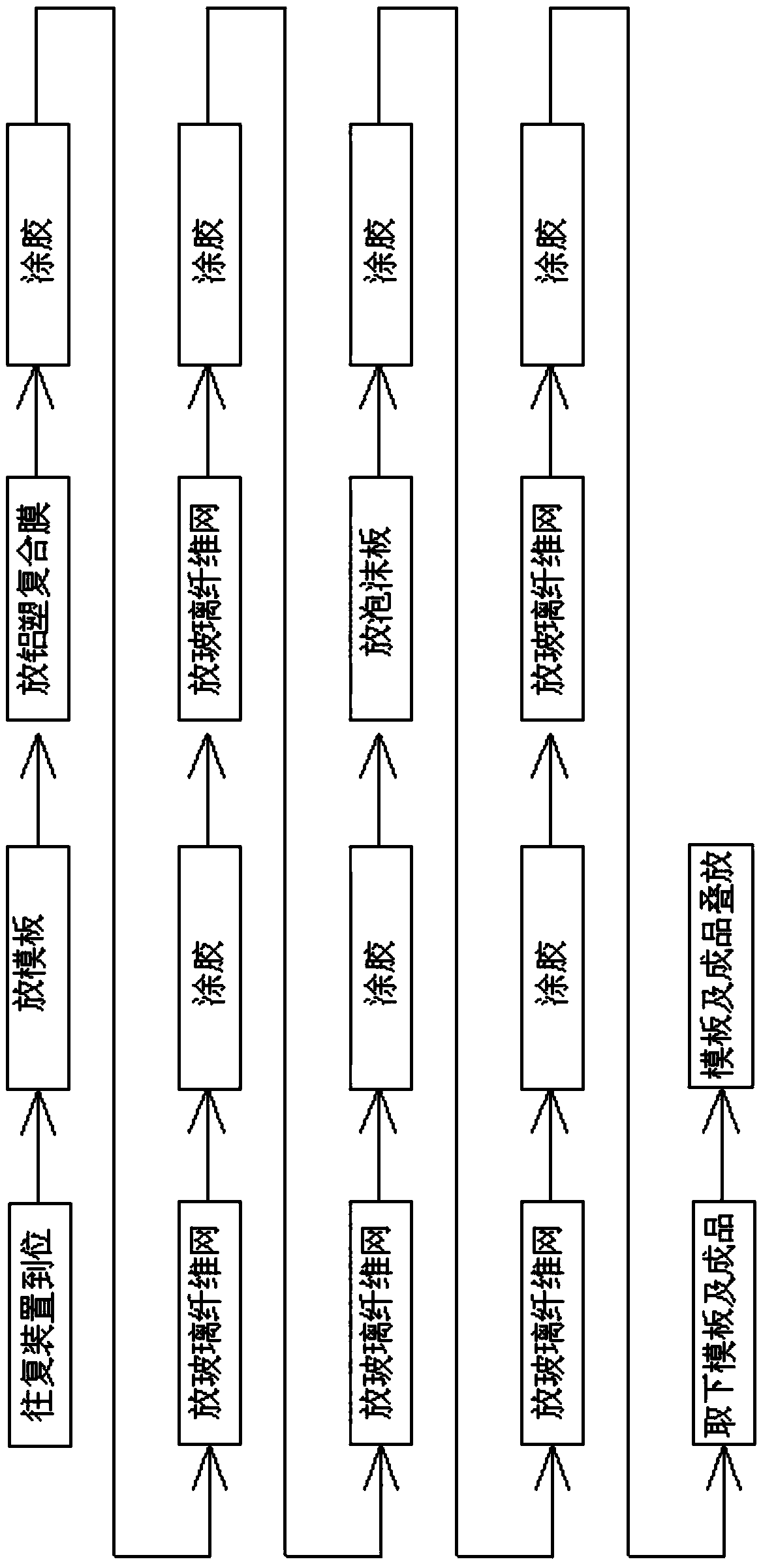

[0036] Stationary magnesite roof panel production equipment, such as figure 1 , figure 2 As shown, it is composed of guide rail 1, formwork reciprocating device 2, formwork 7, formwork and filling board insertion device 3, main machine 5, formwork and finished product take-out device 6, and is characterized in that formwork reciprocating device 2 reciprocates on guide rail 1, and formwork Put the template 7 and the foam board 4 on the template reciprocating device 2, and the main machine 5 lays aluminum-plastic composite film, multi-layer glass fiber mesh, and flame-retardant foam board on the template, and coats the adhesive layer by layer. , the template and finished product take-out device 6 takes out the template and the product together, and stacks them.

[0037] Such as Figure 5 , Figure 6 , Figure 7 As shown, the template 7 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com