A car battery protection structure

A technology for protecting structures and automotive batteries, which is applied to substructures, superstructures, and subassemblies of superstructures. It can solve problems such as collision impact and battery damage, improve rigidity and strength, reduce the risk of battery damage, and reduce the risk of battery damage. The effect of the risk of substantial deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

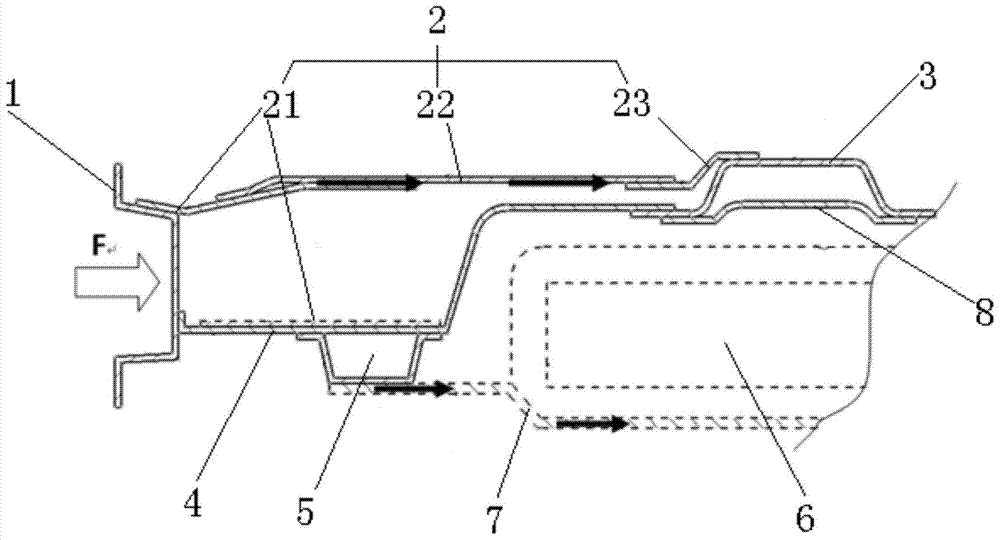

[0030] Such as figure 1 As shown, the embodiment of the present invention provides an automobile battery protection structure, the automobile battery protection structure includes: a middle channel 3 arranged in the middle of the bottom of the vehicle body and longitudinally passing through the vehicle body, located on the left and right sides of the middle channel 3 and symmetrical Two protection assemblies are provided, each protection assembly includes a door sill 1, a seat beam assembly 2, a floor panel 4, and a longitudinal beam 5, one end of the seat beam assembly 2 is connected to the upper part of the door sill 1, and the other One end is connected to the upper end of the middle channel 3, one end of the floor panel 4 is connected to the lower part of the threshold 1, and the other end is connected to the lower end of the middle channel 3, and the longitudinal beam 5 is arranged on the lower surface of the floor panel 4 , and the longitudinal beam 5 runs through the ve...

Embodiment 2

[0036] Such as figure 1 As shown, the embodiment of the present invention provides an automobile battery protection structure, the automobile battery protection structure includes: a middle channel 3 arranged in the middle of the bottom of the vehicle body and longitudinally passing through the vehicle body, located on the left and right sides of the middle channel 3 and symmetrical Two protection assemblies are provided, each protection assembly includes a door sill 1, a seat beam assembly 2, a floor panel 4, and a longitudinal beam 5, one end of the seat beam assembly 2 is connected to the upper part of the door sill 1, and the other One end is connected to the upper end of the middle channel 3, one end of the floor panel 4 is connected to the lower part of the threshold 1, and the other end is connected to the lower end of the middle channel 3, and the longitudinal beam 5 is arranged on the lower surface of the floor panel 4 , and the longitudinal beam 5 runs through the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com