A denitrification device for industrialized circulating aquaculture discharge water and its denitrification process

A circulating aquaculture and water discharge technology, applied in the field of water treatment, can solve problems such as the difficulty in achieving a balance between nitrification and denitrification reactions, secondary pollution of water discharged from aquaculture, and changes in the degree of microbial competition. Good mass transfer effect and reduced pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

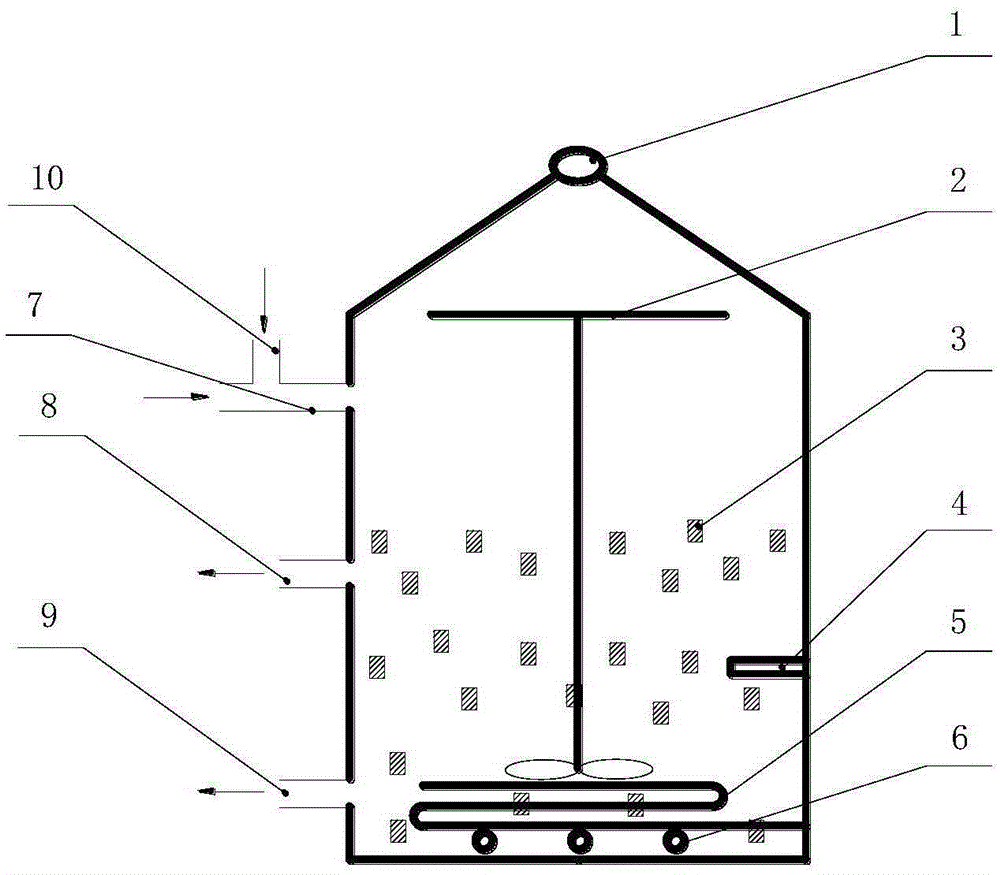

[0033] Such as figure 1 As shown, a factory circulating aquaculture discharge water denitrification device is composed of a cylindrical cylinder and a conical cylinder cover, and the volume of the cylinder is 10m 3 , the cylinder is filled with filler 3, and the filler is laid flat in the cylinder to form a filler layer, and the top of the filler layer is 0.6-0.8m higher than the top of the culture water outlet pipe 8.

[0034] The cone top of the cylinder cover is provided with a gas collection port 1 for collecting and discharging the N produced by denitrification. 2 O gas, reducing pollution to the atmospheric environment.

[0035] The side wall of the cylinder is provided with a culture water inlet pipe 7, a culture water outlet pipe 8 and a backwash outlet pipe 9 from top to bottom; the culture water inlet pipe 7 is connected with a buffer feed pipe 10; An agitator 2 is arranged inside the cylinder, and the bottom of the paddle of the agitator is 0.8-0.9m lower than the...

Embodiment 2

[0046] The design of the denitrification device for industrial circulating aquaculture discharge water is the same as that in Example 1.

[0047] The denitrification process steps of industrial circulating aquaculture discharge water are as follows:

[0048] (1) Fill the cylinder of the industrial circulating aquaculture discharge water denitrification device with filler, and then add activated sludge and aquaculture discharge water. The volume ratio of activated sludge and aquaculture discharge water is 1:1, and the membrane is started , the time is 20 days to form a biofilm;

[0049] (2), after biofilm formation, inject grouper culture discharge water from culture water inlet pipe, the dissolved oxygen of this discharge water is 7.5mg / L, ammonia nitrogen concentration is 4mg / L, and nitrate concentration is 100mg / L. Turn on the stirrer to stir at a speed of 100rpm, start the heat exchanger, turn on the aeration head to increase oxygen, and heat until the water temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com