Cantilever type detachable fastener

A cantilever and buckle technology, which is applied in the direction of connecting components, pins, deformed pins, etc., can solve problems such as easy release, snap release, cantilever root or buckle breakage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

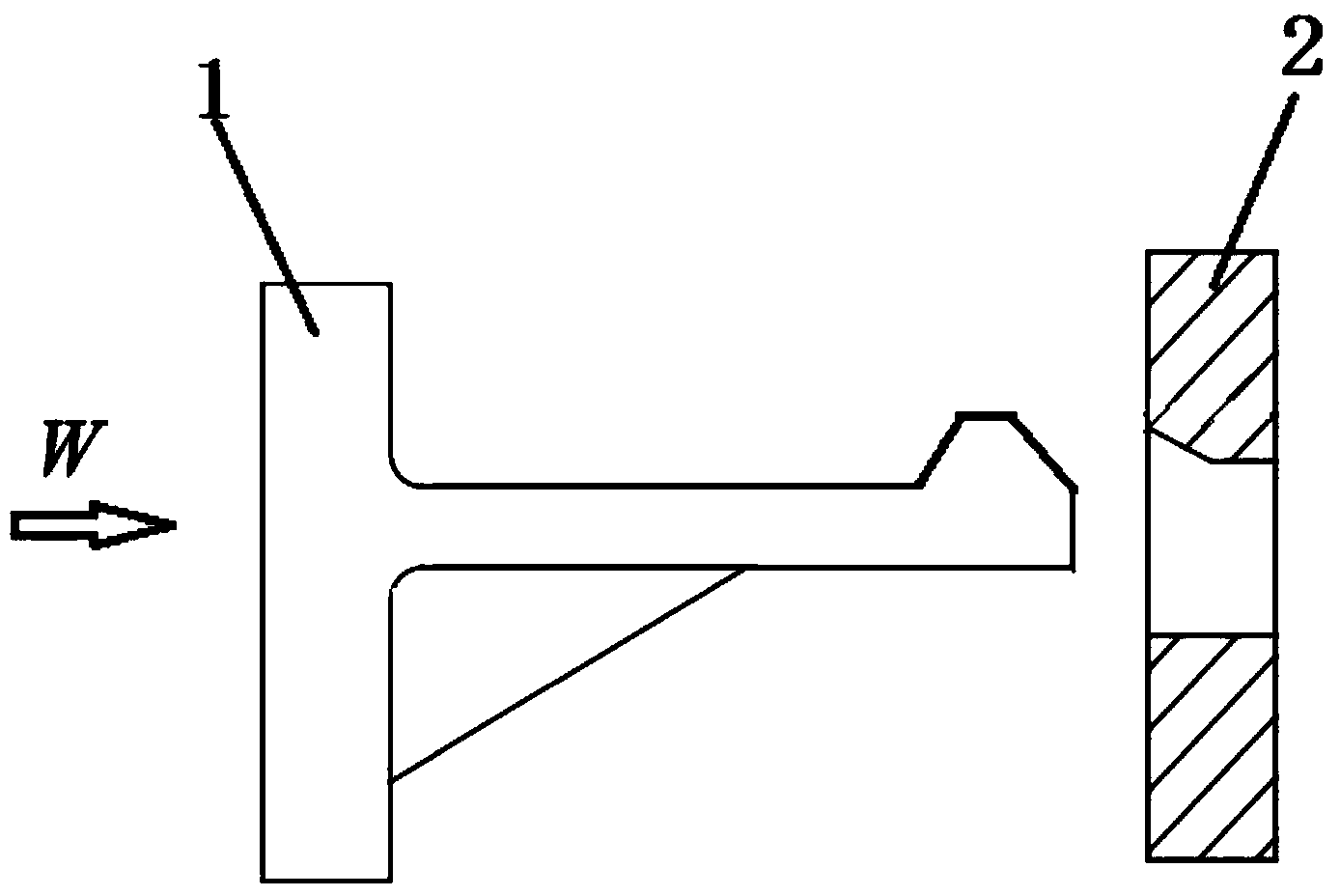

[0016] figure 1 Shown is an embodiment of the cantilever type detachable buckle of the present invention, including a cantilever fastener and a locking element. The length of the cantilever beam of the cantilever fastener is 5 to 9 times the thickness of the cantilever beam. When it is less than 5 times the cantilever elasticity is poor, it is easy to cause the cantilever to break at the root. When it is greater than 9 times, the cantilever is easy to deform and injection mold filling is difficult. .

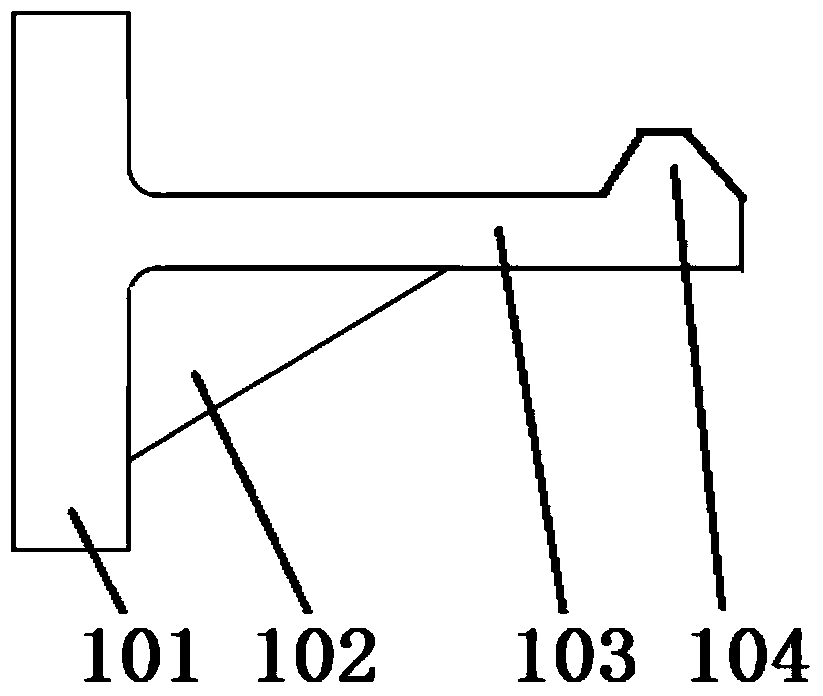

[0017] The cantilever beam adopts a rectangular variable-section cantilever, the width of the cantilever beam top is 0.25 times of the cantilever beam root width, and the cantilever beam width decreases linearly from the root to the top, and the amount of deformation incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com