Proportional electromagnetic valve driving method and system based on PWM (Pulse Width Modulation)

A proportional solenoid valve and driving method technology, applied in valve details, valve devices, engine components, etc., can solve the problems of proportional solenoid valve secondary pressure fluctuation, multiple power loss, increasing solenoid valve hysteresis loss and eddy current loss, etc. Achieve stable output pressure, reduce power consumption, and prevent spool sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

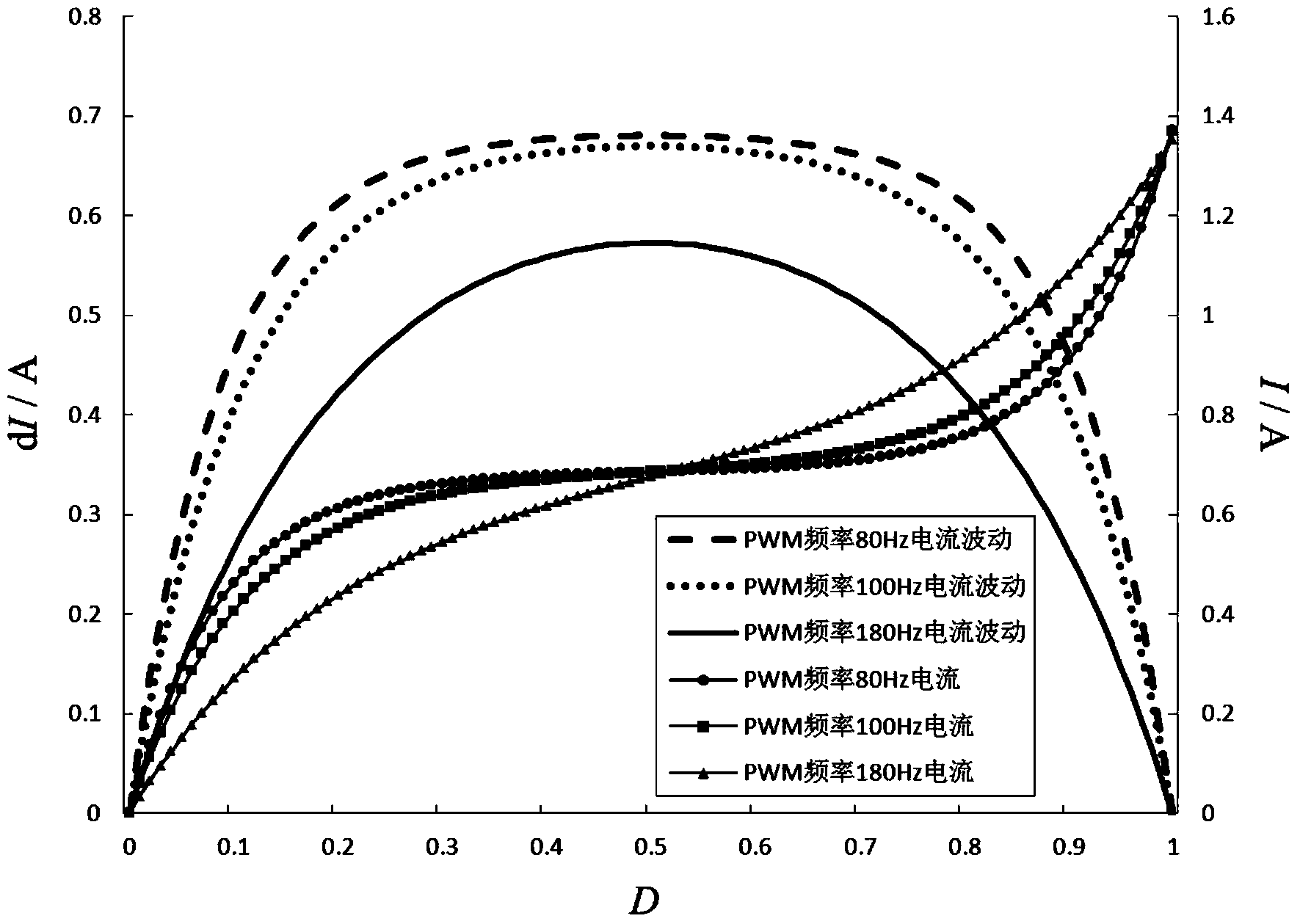

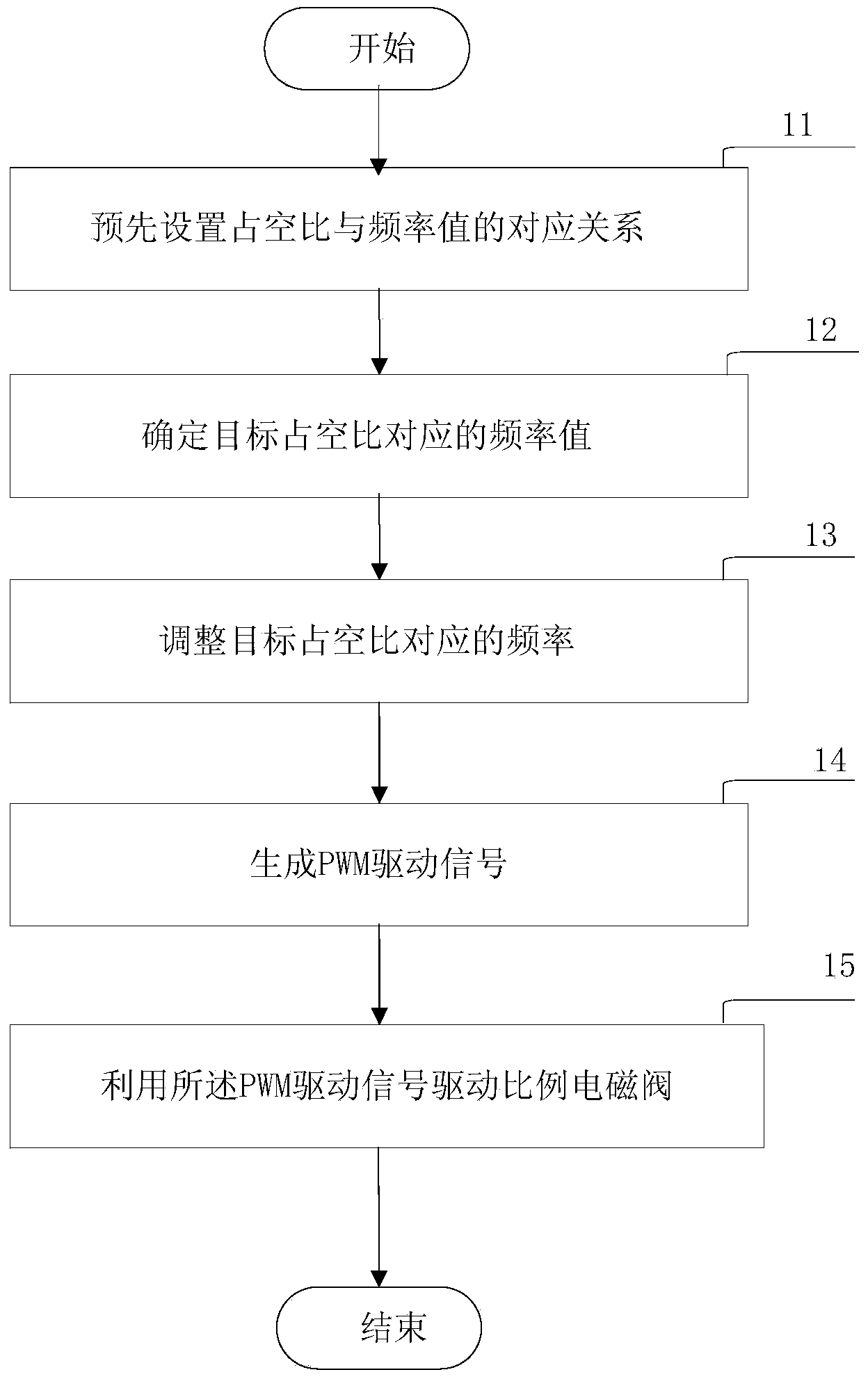

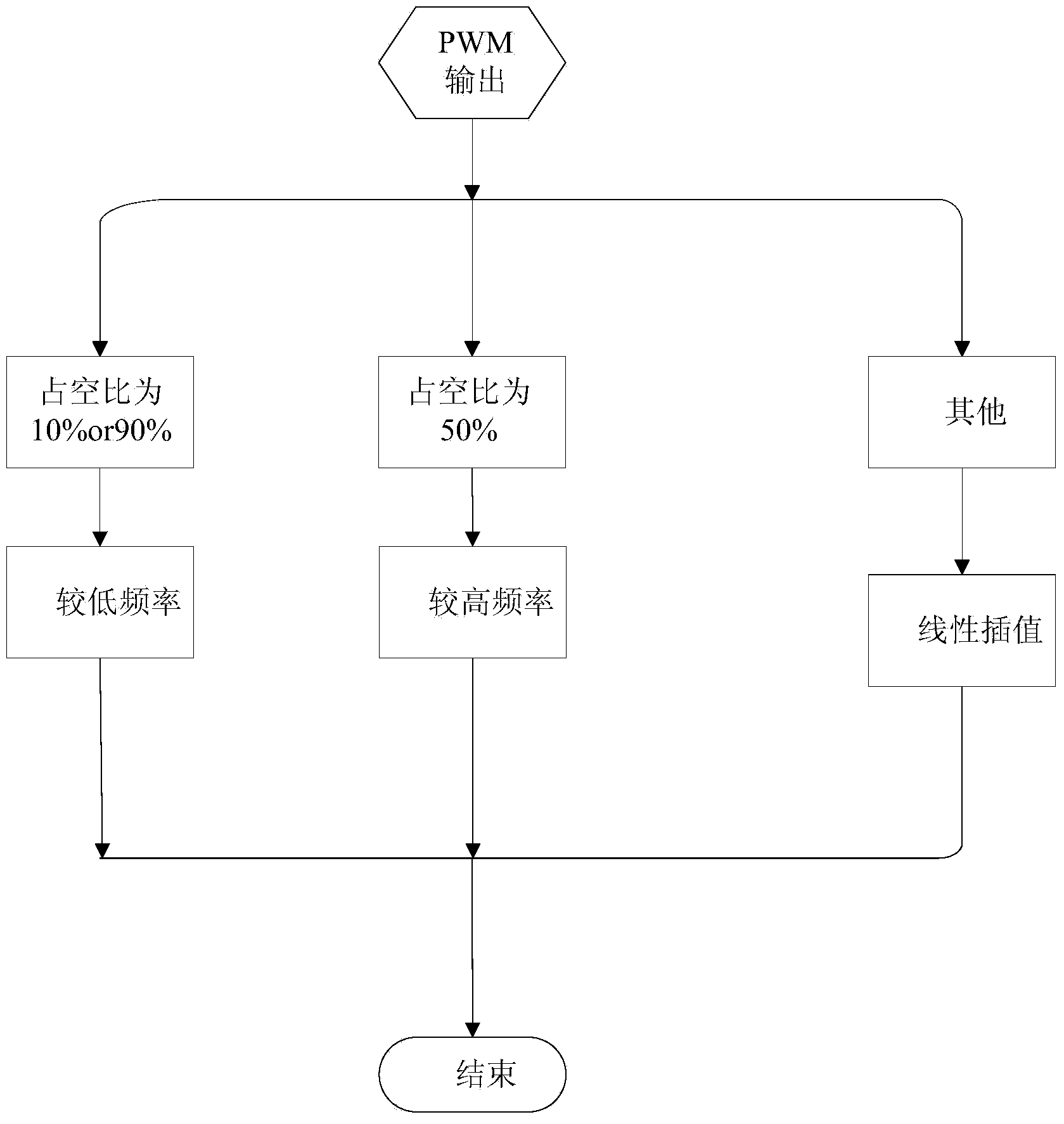

[0024] The theoretical basis of this application is: in view of the fact that the proportional electromagnet belongs to the excitation type electro-mechanical conversion device, the control current generated by the embedded controller generates magnetic flux in the proportional electromagnet coil to push the armature to displace, and the electromagnetic force received by the valve core has the same The current fluctuates at the same frequency. Comprehensive consideration of the electromechanical hydraulic system of the proportional solenoid valve shows that part of the transfer function of the mechanical system can be used as a low-pass second-order filter, while the transfer function of the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com