Novel power-plant raw water and boiler raw water heating system and method

A raw system and raw water technology, applied in chemical instruments and methods, separation methods, feed water heaters, etc., can solve problems such as non-compliant temperature matching, energy waste, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

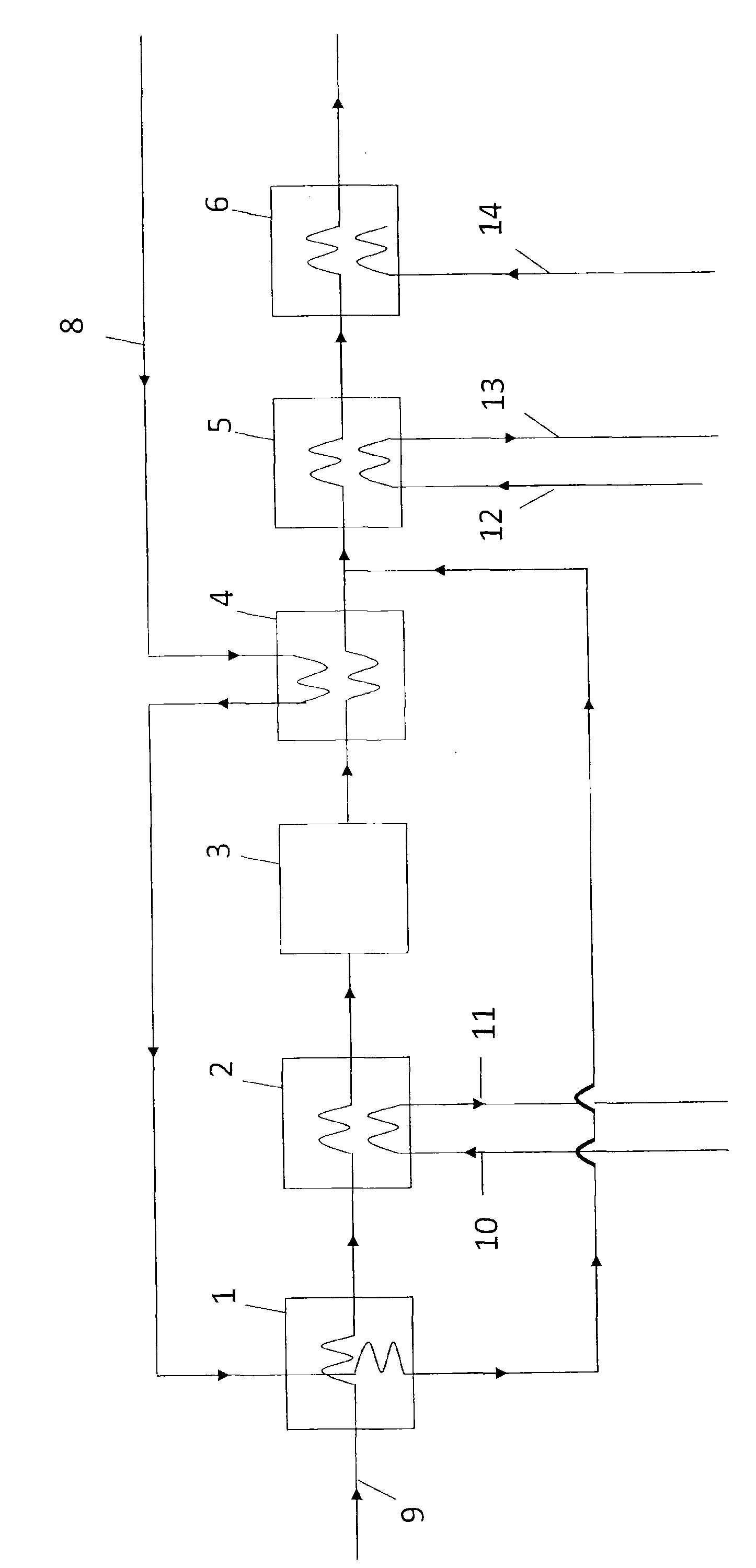

Embodiment 1

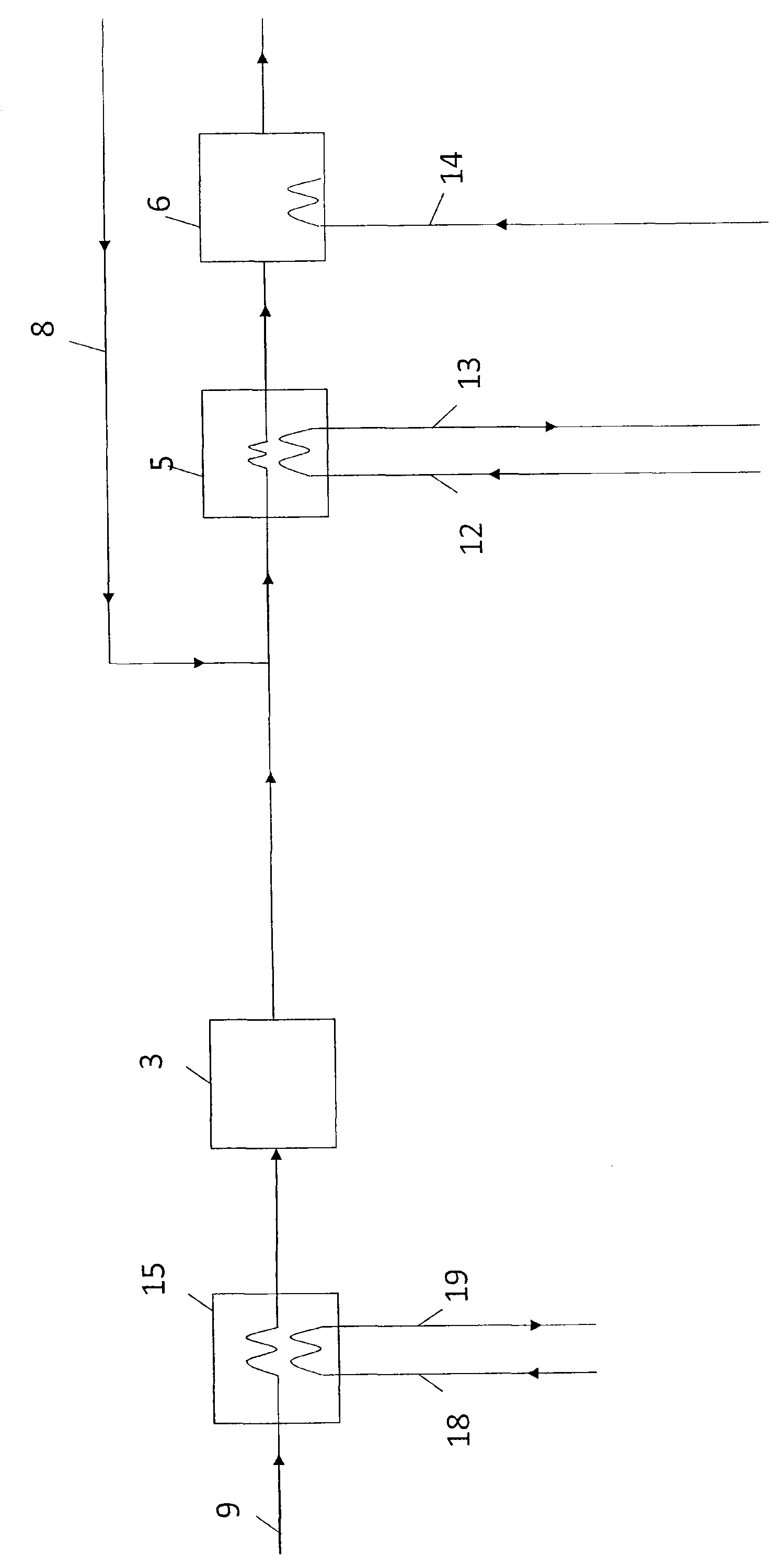

[0017] A new system for heating power plant and boiler raw water, such as figure 2 As shown, the condensed water recovery pipeline 8 of the original system is connected to the raw water pipeline 9 . The raw water pipeline 9 is sequentially connected to the low-temperature waste heat raw water heating device 15 , the original system raw water desalination device 3 , the original system condensed water recovery pipeline 8 , the original system high-temperature waste heat recovery heating device 5 , and the original system low-temperature deoxygenation device 6 . The low-temperature waste heat raw water heating device 15 is respectively connected with the low-temperature waste heat raw water heating device hot flow pipe 18 and the low-temperature waste heat raw water heating device cold flow pipe 19 . The original system high temperature waste heat recovery heating device 5 is respectively connected to the original system high temperature waste heat recovery heat flow pipe 12 an...

Embodiment 2

[0024] A new system for heating power plant and boiler raw water, such as image 3 As shown, its structure is basically the same as that of Embodiment 1, except that: a medium-temperature waste heat raw water heating device 24 is connected in series between the original system raw water desalination device 3 and the original system high-temperature waste heat recovery heating device 5 . The medium-temperature residual waste heat raw water heating device 24 is connected to the medium-temperature residual waste heat raw water heating device hot flow pipeline 25 and the medium-temperature residual waste heat raw water heating device cold flow pipeline 26 respectively.

[0025] work process:

[0026] The condensed water passes through the condensed water recovery pipeline 8 of the original system to the raw water pipeline 9 and is mixed with the raw water in the raw water pipeline 9. The mixed water is heated through the raw water pipeline 9 to the high-temperature waste heat rec...

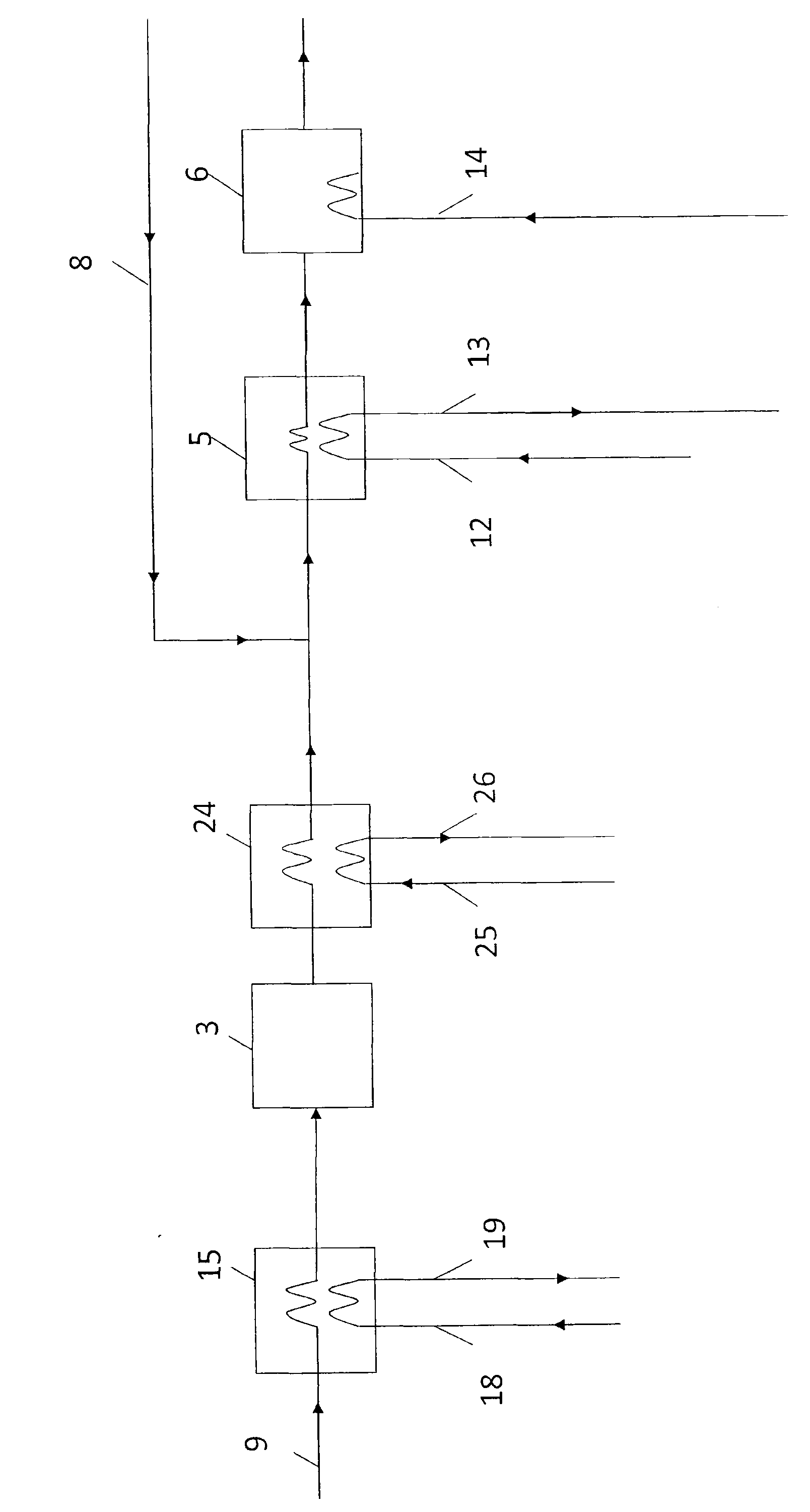

Embodiment 3

[0032] A new method of heating raw water for power plants and boilers, such as Figure 4 As shown, the original system condensate recovery pipeline 8 is connected to the original system condensate waste heat recovery heating device 2 4 , high-temperature waste heat heat pump heating device 17 , and raw water pipeline 9 in sequence. The raw water pipeline 9 is sequentially connected to the low-temperature waste heat raw water heating device 15, the original system raw water desalination device 3, the original system condensate recovery pipeline 8, the medium temperature waste heat raw water heating device 24, and the original system condensate waste heat recovery heating device 24 . High-temperature waste heat heat pump heating device 17. Original system high-temperature waste heat recovery heating device 5. Original system low-temperature oxygen removal device 6. The low-temperature waste heat raw water heating device 15 is respectively connected with the low-temperature waste...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap