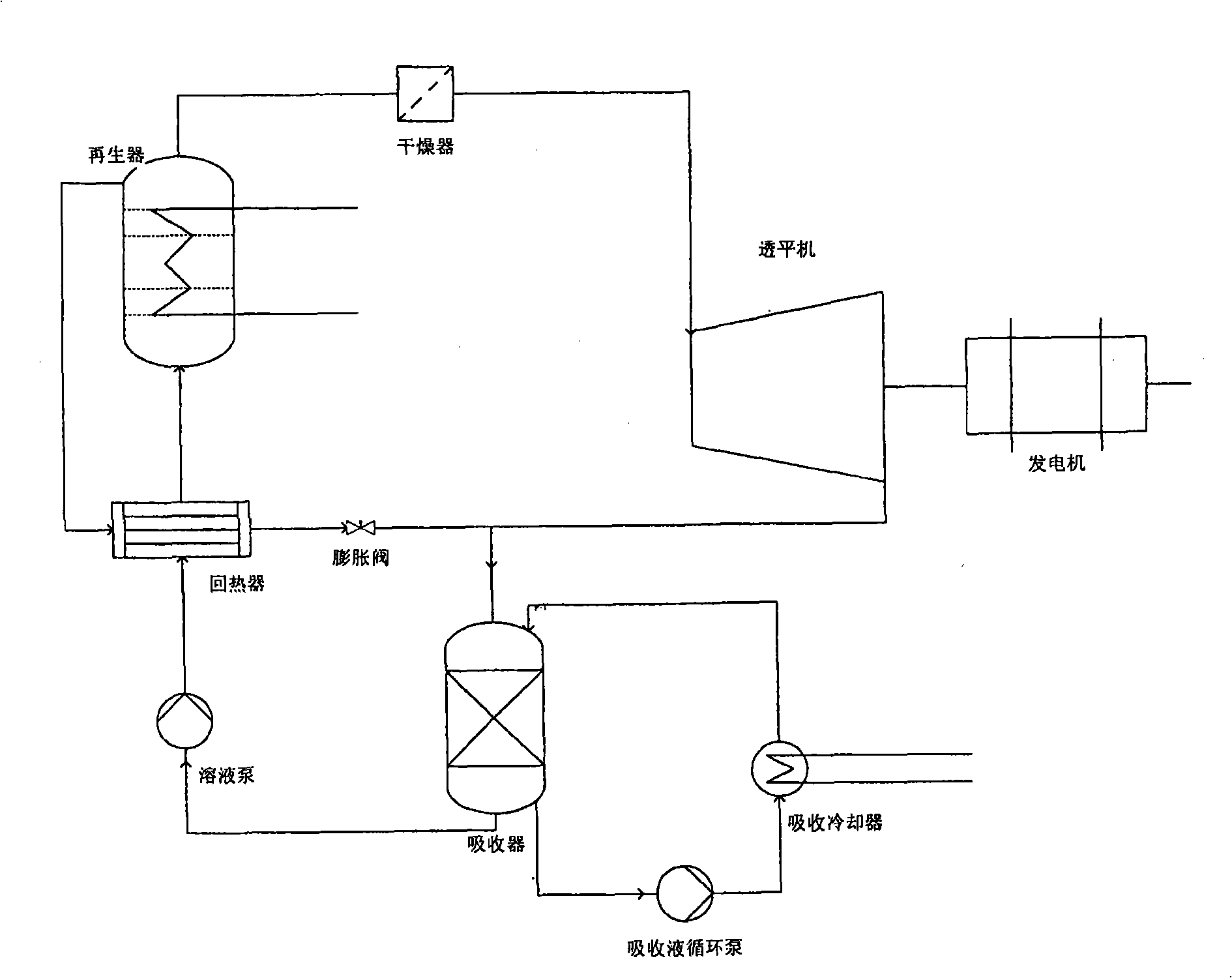

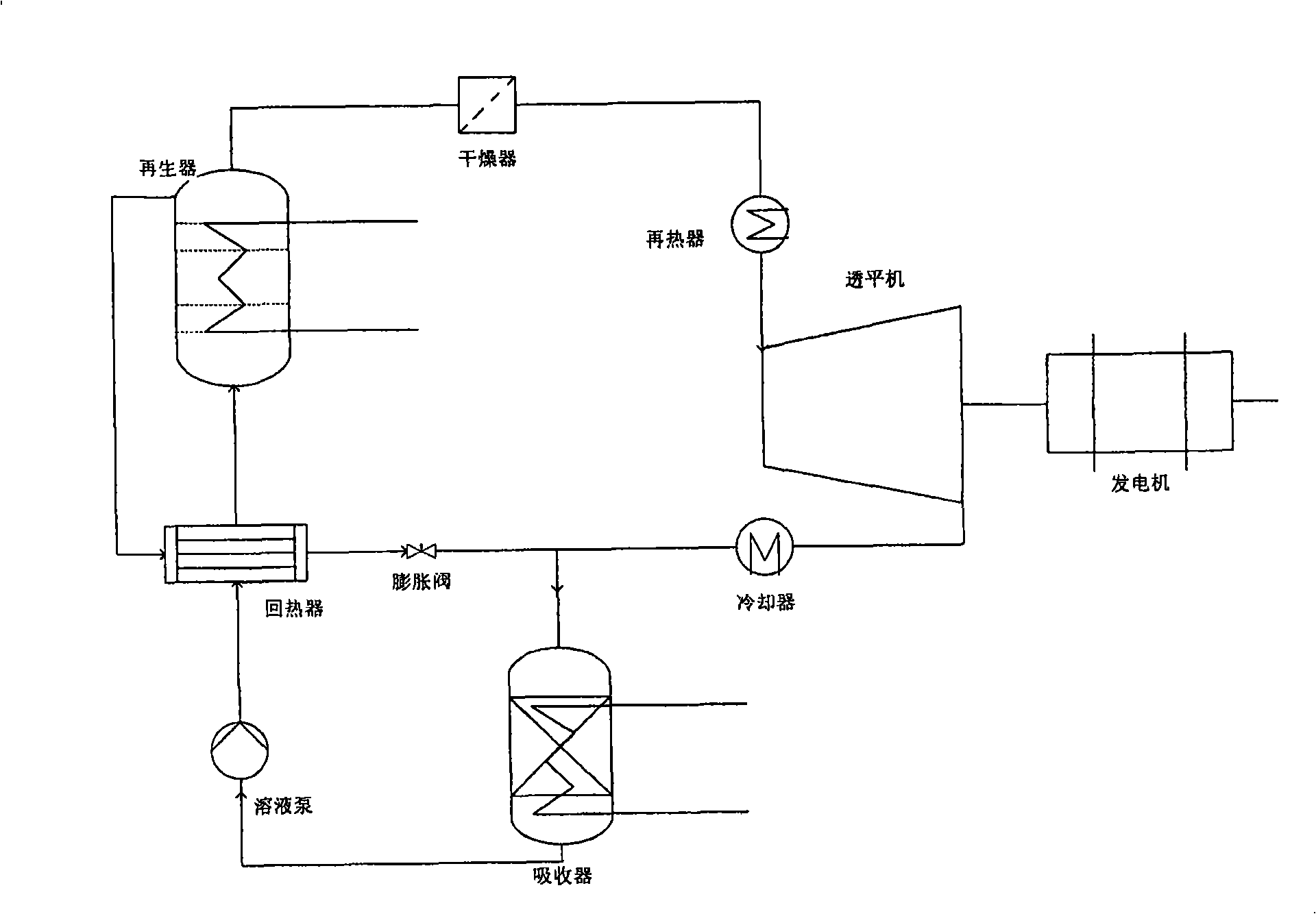

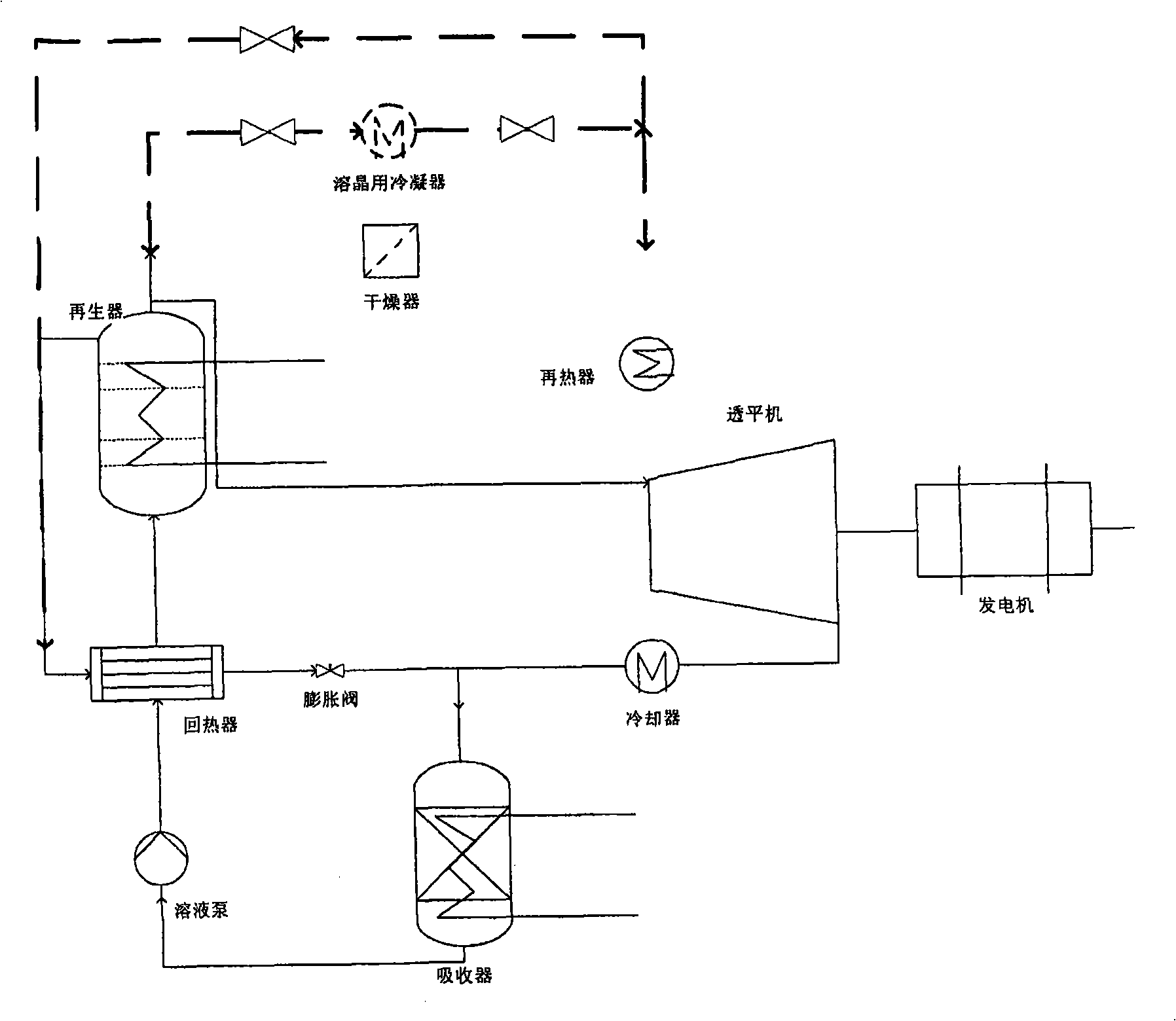

Residual heat reclaiming method, residual heat reclaiming system and used working fluid of absorption liquid

A technology of working fluid and absorbing liquid, which is applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve the problems of high equipment cost and energy consumption, and achieve the effect of saving equipment investment, high energy density and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] In this embodiment, low-temperature waste heat at 90° C. to 120° C. discharged from an oil refinery with an annual output of 5 million tons of oil products of Huabei Petrochemical Company is used as a heat source to introduce the waste heat recovery cycle system of the present invention. The equipment used in the system and its working conditions are as follows:

[0038] 1. As the heater of the regenerator: shell-and-tube heat exchanger, the absorption liquid is anhydrous ammonia-thiocyanate sodium salt solution and goes through the tube side.

[0039] Selection parameters:

[0040] 1) The inlet temperature of the heat source is 120°C-130°C, and the outlet temperature of the heat source is 90°C;

[0041] 2) NH 3 - The inlet and outlet temperatures of the sodium thiocyanate solution are 86°C and 110°C respectively;

[0042] 3) heat transfer ≥ 425.18kW;

[0043] 4) Fixed tube plate type, the design pressure is 2.5MPa, and the maximum working pressure is 1.8MPa;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com