Stirring device

A processing device and a rotating shaft technology, applied in the direction of local stirring dryers, lighting and heating equipment, dryers, etc., can solve the problems of heat transfer efficiency decline, etc., to suppress the generation of air locks, suppress the reduction of heat transfer efficiency, and improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

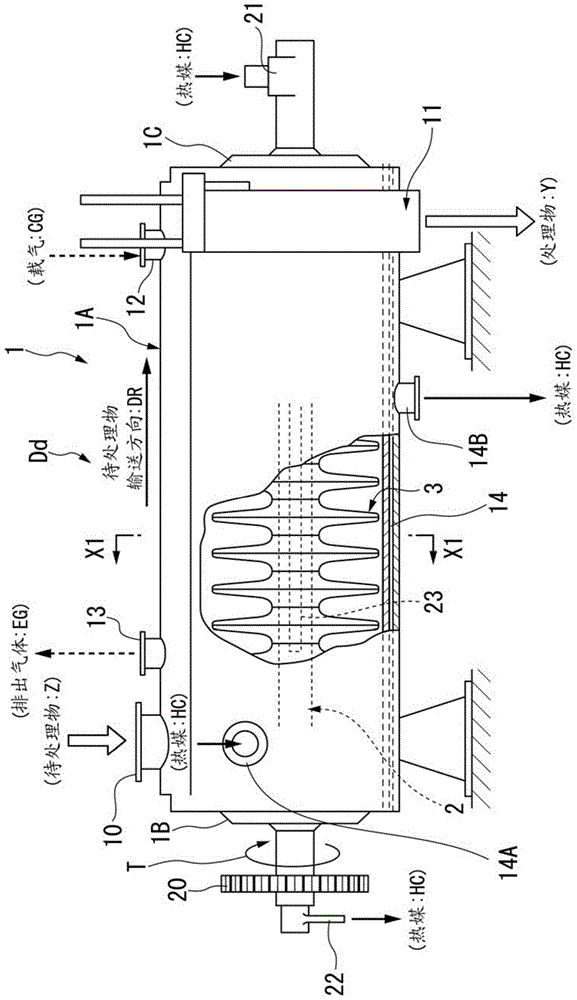

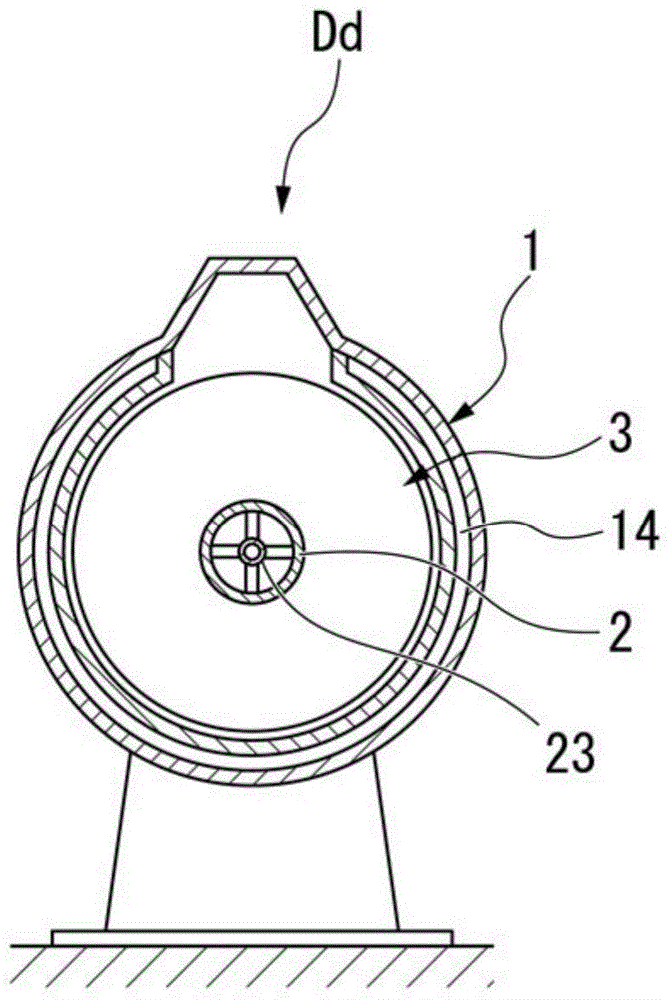

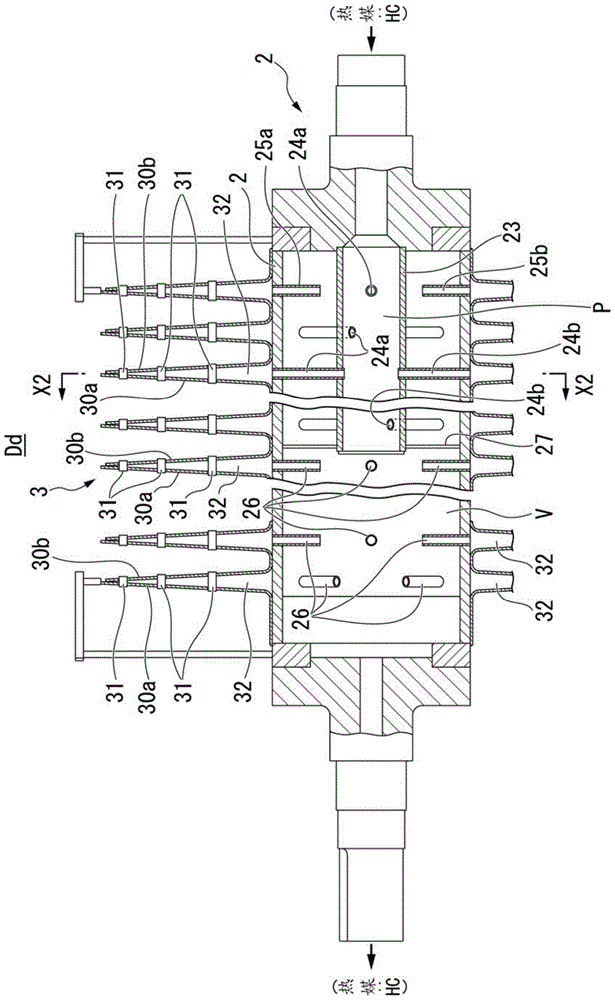

[0039] Below, refer to Figure 1 to Figure 4 , the first embodiment of the present invention will be described.

[0040] figure 1 It is a partial cross-sectional view of an example of a schematic structure of a disk-shaped processing device (stirring processing device) according to the first embodiment viewed from the front, and reference numeral Dd denotes a disk-shaped processing device, and reference numeral 3 denotes a disk.

[0041] Such as figure 1 As shown, the disc-type drying processing device Dd according to the first embodiment includes a cylinder 1, a hollow rotating shaft (rotating shaft) 2, and a disc 3 (heat transfer member, heat transfer disc).

[0042] The cylinder 1 includes a cylindrical body 1A formed in a cylindrical shape, fixed side wall portions (fixed members) 1B and fixed side wall portions (fixed members) 1C formed at both ends of the cylindrical body 1A, and is configured to have a predetermined Cylindrical type of the space of the capacity.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com