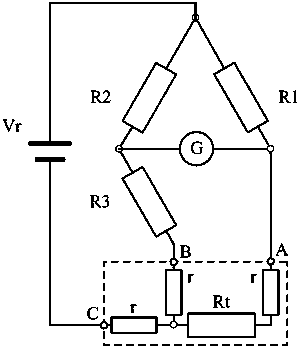

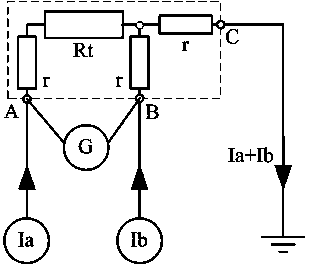

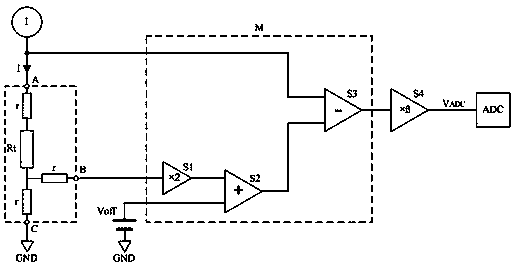

Three-wire-system thermal resistor measuring circuit

A technology for measuring circuits and thermal resistances, applied in measuring devices, measuring heat, thermometers using electrical/magnetic components directly sensitive to heat, etc. Improve temperature measurement accuracy, avoid measurement errors, and achieve the effect of simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Existing technology uses dual constant current source excitation for the measurement of thermal resistance, and there is a measurement error caused by the inconsistency of the dual constant current source; the prior art uses a multiplex switch (MUX) to switch the connection between the dual constant current source and the thermal resistance The method of measuring the thermal resistance twice before and after and calculating the average value can solve the problem of measurement error caused by the inconsistency of the double constant current source, and additionally increase the complexity of the control circuit, which is not conducive to the remote measurement of temperature.

[0024] In order to overcome the defects in the prior art, the present invention provides a three-wire thermal resistance measurement circuit with a single const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com