A Modeling Method of Tool Sweeping Volume

A modeling method and scanning volume technology, applied in the field of numerical control, can solve the problems of time-consuming calculation process and high time complexity of tool scanning volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0056] The present invention comprises the following steps (as Figure 5 shown):

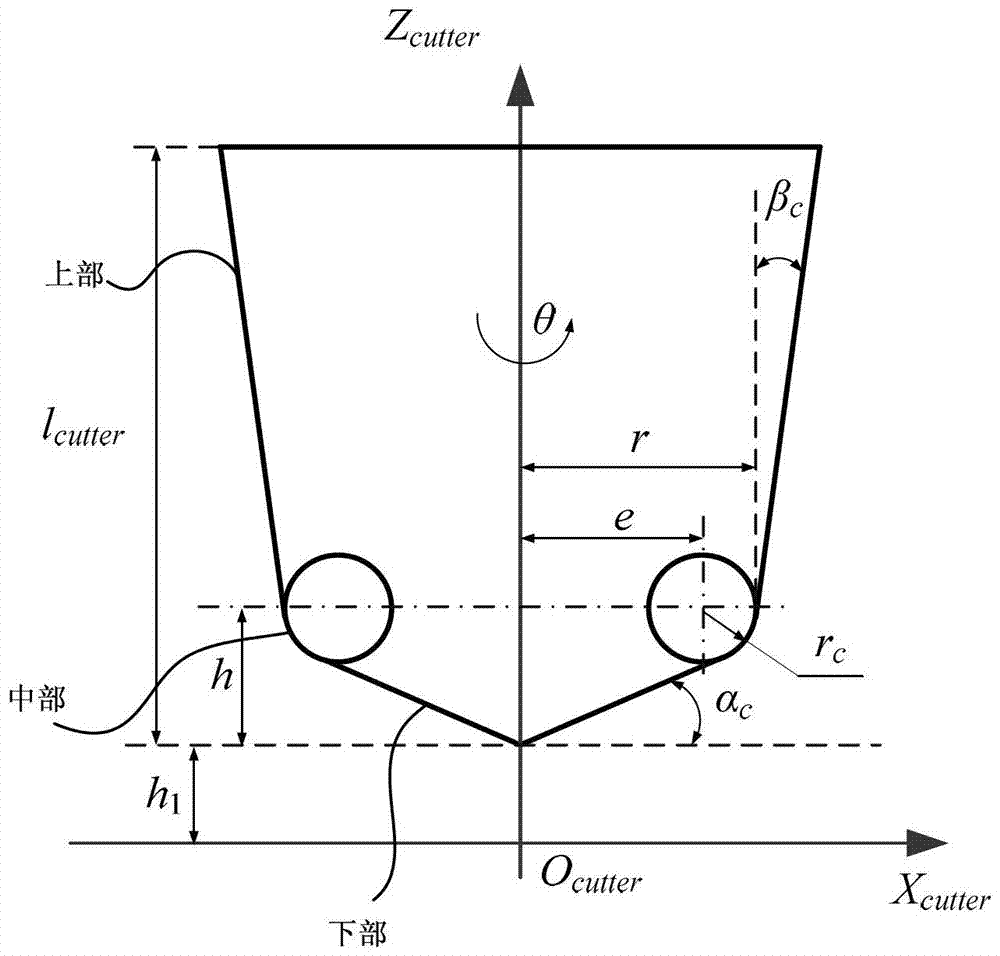

[0057] According to the general tool model (such as figure 1 shown) to calculate the implicit function expression T(x, y, z)=0 of the tool in the tool frame system;

[0058] The implicit function expression of the general tool model in the tool frame system is specifically:

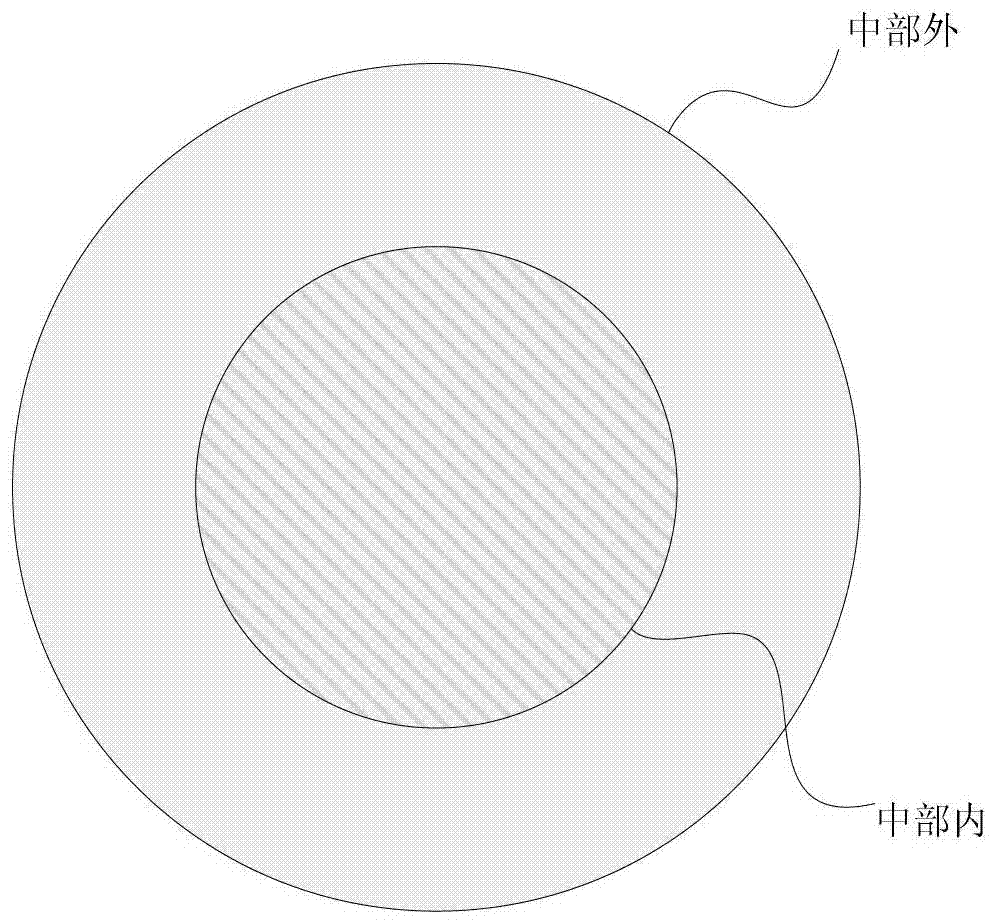

[0059] The implicit function expression of the general tool model is divided into three parts, namely the upper part, the middle part and the lower part (such as figure 1 shown). Among them, the central part is divided into the outer part and the inner part (such as figure 2 shown).

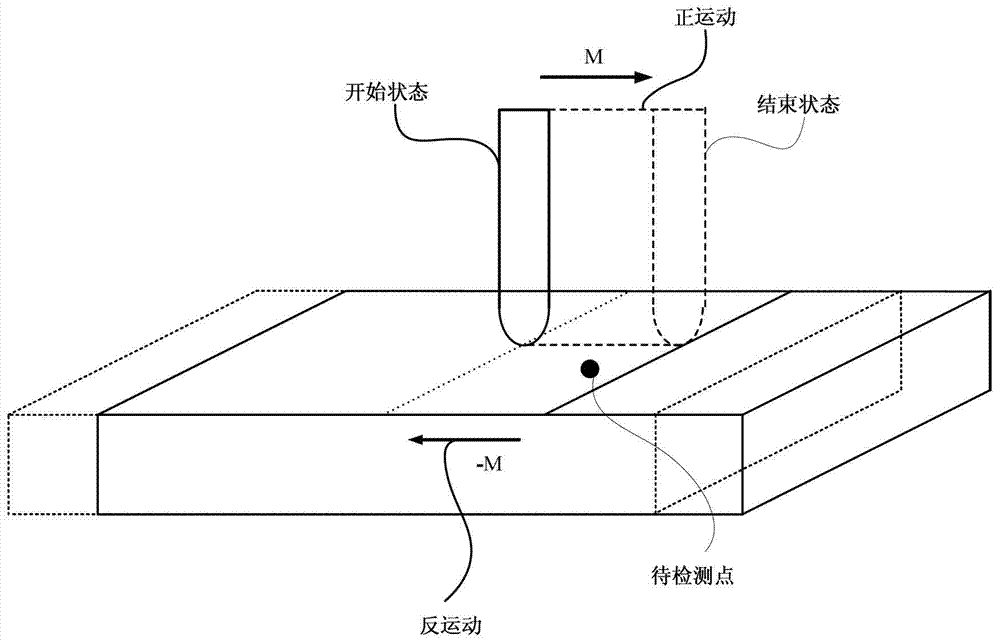

[0060] According to the frame theory of rigid body motion and the inverse kinematic relationship between the tool and the workpiece. Calculate the conversion relationship between the tool frame system and the workpiece frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com