Rail transit cable with oxygen isolating layer and manufacturing method thereof

A rail transit and oxygen barrier technology, applied in the direction of insulating cables, cables, circuits, etc., can solve problems such as insulation layer aging, personal and property safety accidents, power supply or signal interruption, etc., to improve the flame retardant level, protect the environment, The effect of fire avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, illustrate the concrete content of the present invention in detail:

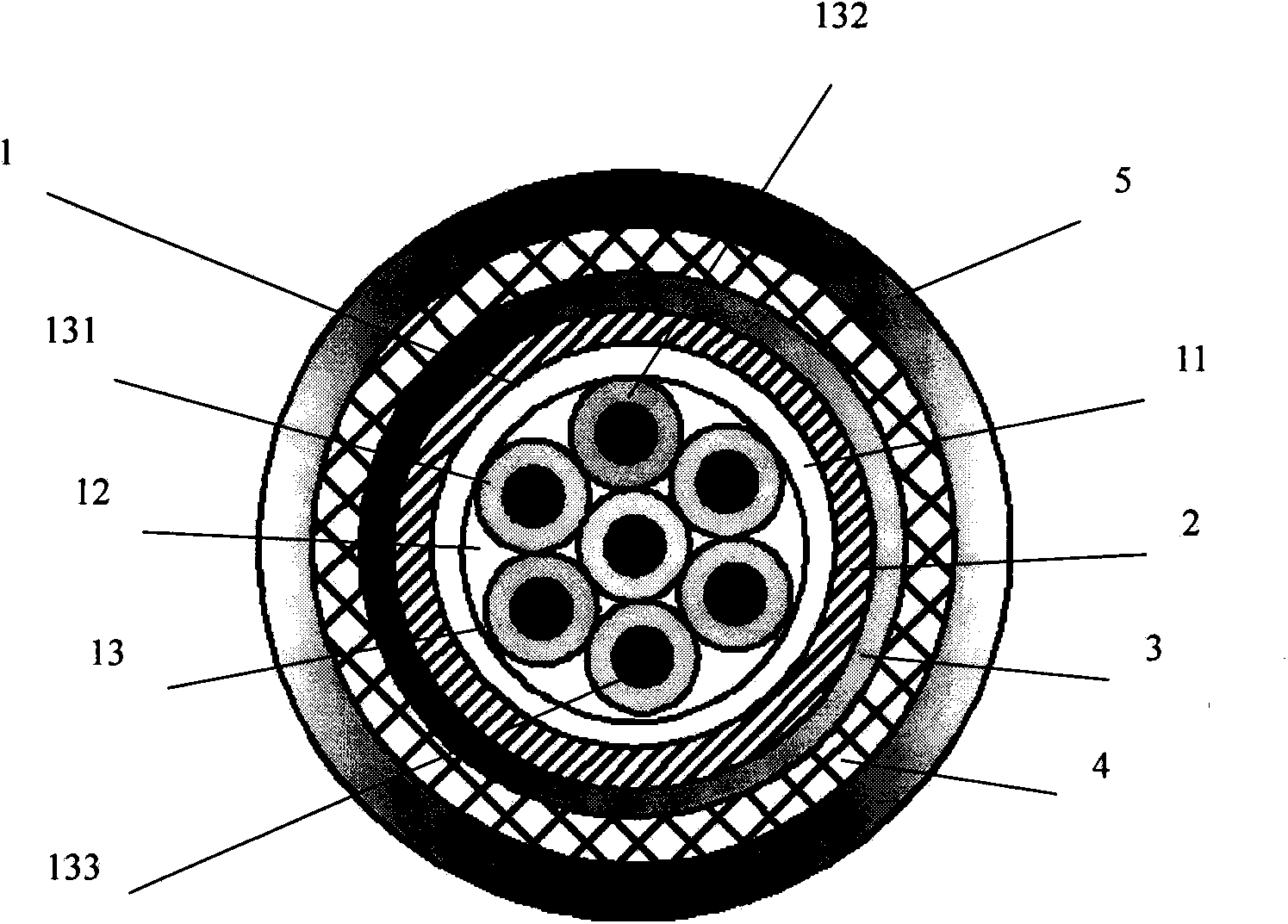

[0017] like figure 1 The rail transit cable shown is mainly a cable core unit 1 composed of 7 insulated wire cores 13 plus 11 layers of insulating tape, and a filler 12 is densely filled therein. Add an environmentally friendly flame-retardant oxygen barrier tape layer 2 and a thermoplastic oxygen barrier layer 3 outside the cable core unit, add an armor layer 4 outside the oxygen barrier layer, and extrude a sheath 5 outside the armor layer to closely adhere to the armor layer .

[0018] In order to ensure that the power supply or signal is not interrupted immediately after the cable catches fire, a layer of phlogopite mica tape 132 is coated on the conductor as a refractory layer.

[0019] In order to delay the burning speed, the gap in the cable core is densely filled with flame-retardant filling rope 12 to minimize the air area.

[0020] The insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com