Manufacturing method of shallow trench isolation

A manufacturing method and shallow trench technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of uneven thickness of linear oxide layer, STI leakage, etc., and achieve better reliability and insulation. and good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The core idea of the present invention is to provide a manufacturing method of shallow trench isolation, the manufacturing method of shallow trench isolation performs a nitrogen doping process on the trench sidewall before forming the linear oxide layer, and suppresses the formation of the trench sidewall. The thickness of the linear oxide layer is grown so that the linear oxide layer of the STI can grow uniformly on the sidewall and bottom of the trench during the growth process. In this way, it can be prevented that the linear oxide layer on the sidewall of the trench is too thick to be etched in a subsequent step, resulting in the problem that the linear oxide layer at the bottom is too thin to cause electric leakage. And after the treatment of nitrogen doping process, the reliability and insulation of STI are greatly improved.

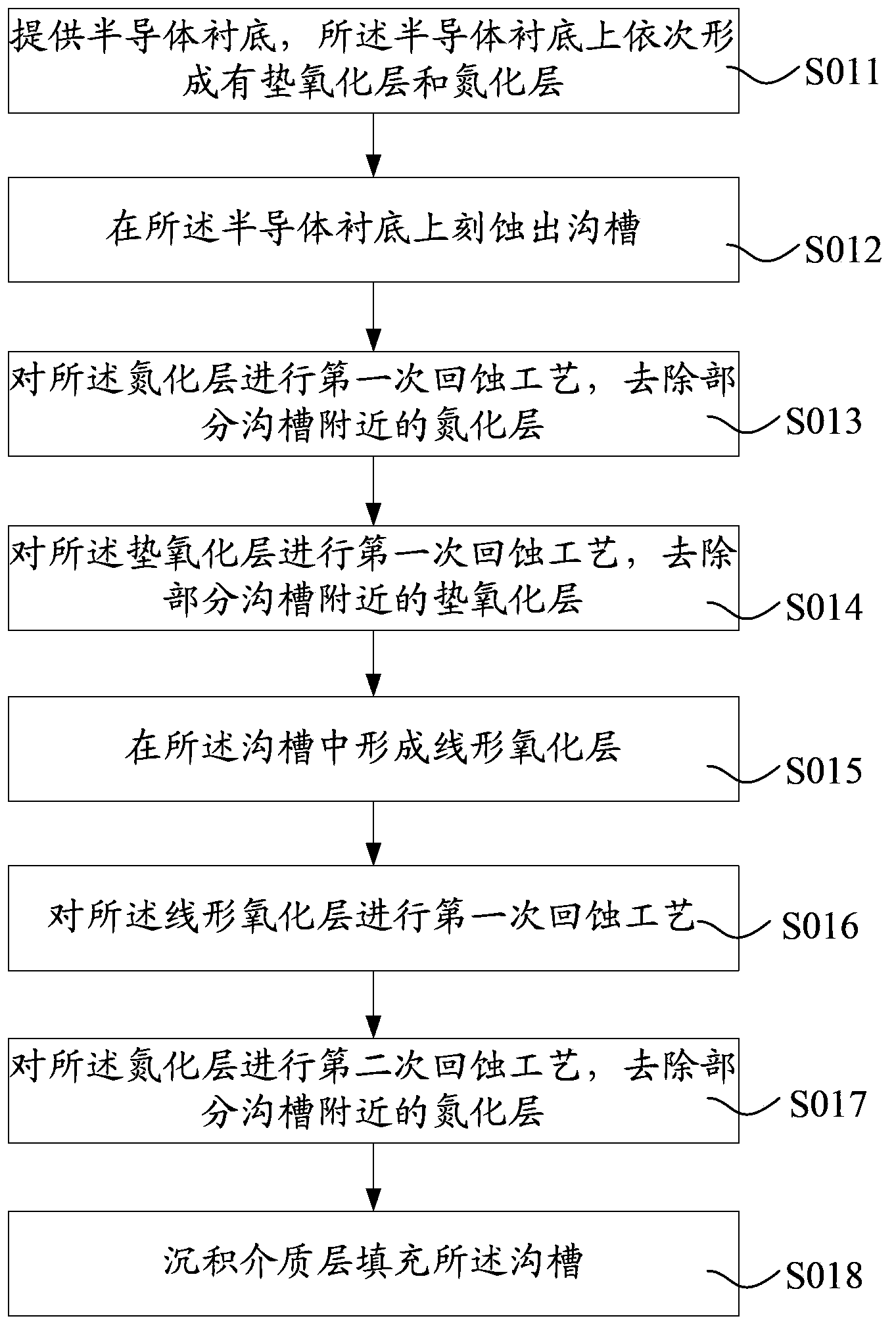

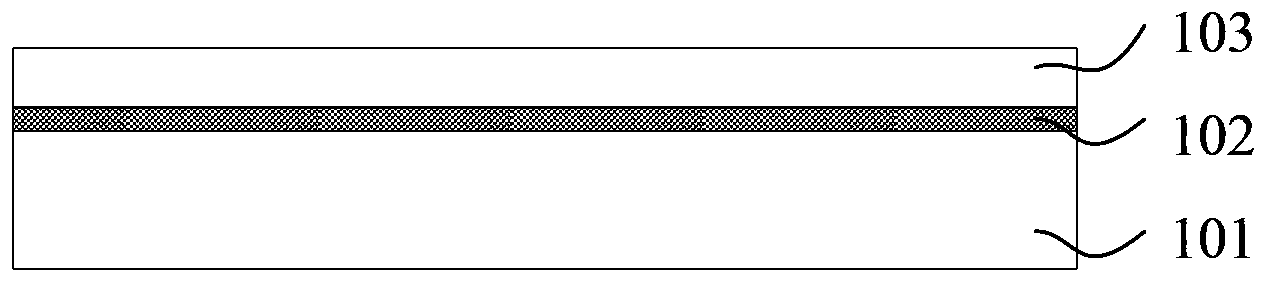

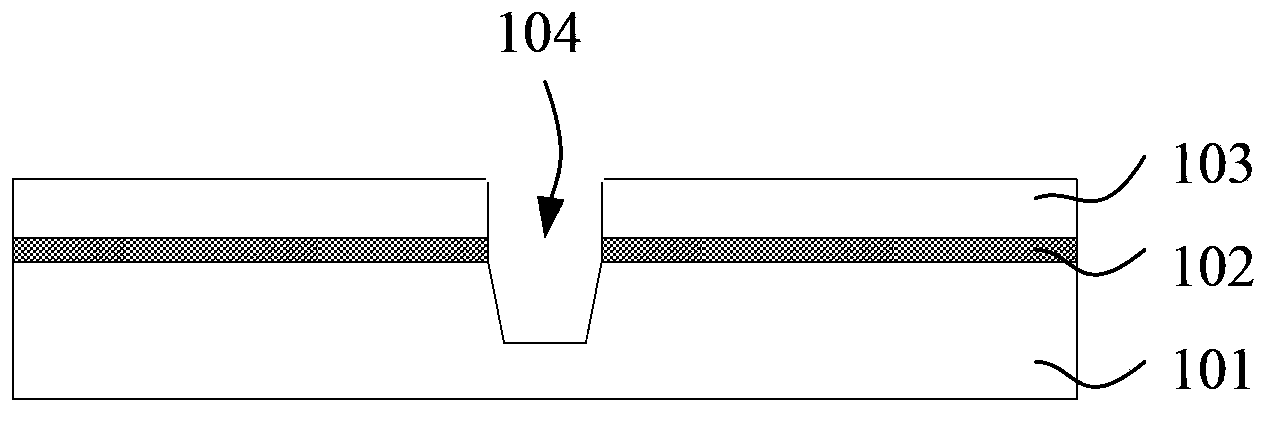

[0030] combine image 3 , is a flowchart of a method for manufacturing shallow trench isolation according to an embodiment of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com