Charging and discharging method of battery pack

A battery pack, charging and discharging technology, applied in battery circuit devices, arrangement of multiple synchronous batteries, collectors, etc., can solve the problems of battery discharge energy waste, heavy burden on the power grid, and large charging and discharging current, and achieve low energy consumption , reduce the types of equipment, and stabilize the voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

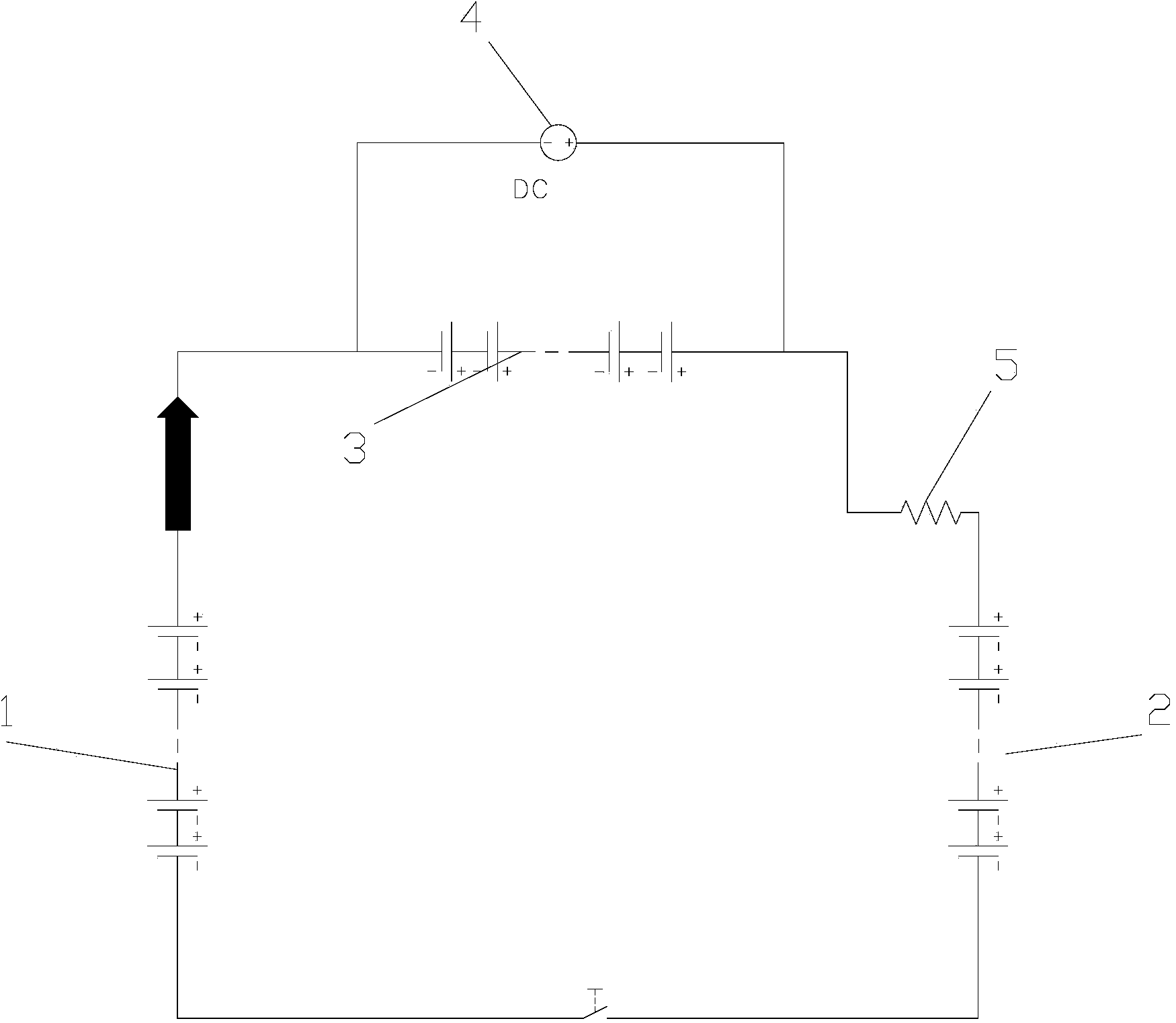

[0024] refer to figure 1 , the charging and discharging method of the battery pack, comprising a discharge battery pack 1 and a rechargeable battery pack 2, there is a voltage difference between the discharge battery pack 1 and the rechargeable battery pack 2, and a step-up energy storage battery is connected in series on the discharge battery pack 1 After group 3, it is connected in parallel with rechargeable battery pack 2 to form a charge-discharge circuit. , the rechargeable battery pack 2 is charged together with the boost energy storage battery pack 3 . The present invention utilizes the pressure difference to realize energy recovery, realizes the charging of the rechargeable battery pack 2 while the discharge battery pack 1 is discharging, makes good use of energy, consumes less energy, and has high efficiency, and boosts the energy storage battery pack 3 through charging The circuit 4 is always maintained in a steady voltage state, which can control the direction of t...

Embodiment 2

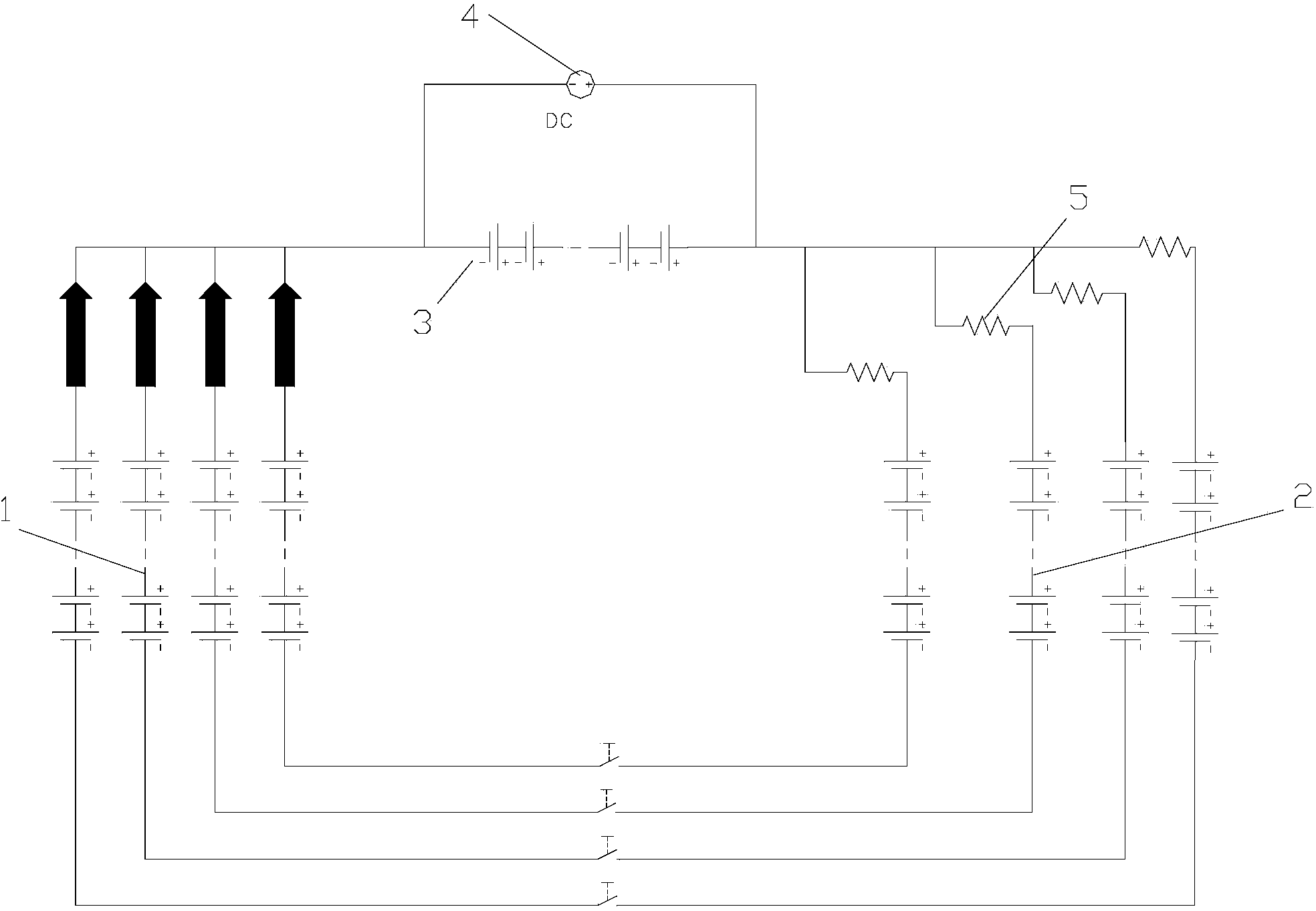

[0031] refer to figure 2 , the difference between this embodiment and Embodiment 1 is that the discharge battery pack 1 is a plurality of discharge battery packs, and the rechargeable battery pack 2 is also a plurality of rechargeable battery packs, each discharge battery pack 1 and one or more After a boosted energy storage battery pack 3 is connected in series, it can form an independent charge-discharge circuit with a corresponding rechargeable battery pack 2 . In this embodiment, multiple charging and discharging circuits can be formed, so that the charging and discharging efficiency is high. The rest of the structures and functions are the same as those in Embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap