Loess engineering property modification method

A technology of engineering properties and loess, which is applied in the field of engineering properties modification of loess, can solve the problems of other materials that are less studied, and achieve the effects of reducing water sensitivity, reducing collapsibility, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Modification method of engineering properties of loess:

[0027] The construction method of cement kiln dust modified loess comprises the following steps:

[0028] (1), loess and cement kiln dust are carried out air-drying, cross 2mm sieve;

[0029] (2), the loess and cement kiln dust after step (1) air-dried and sieved are mixed evenly in the ratio of dry mass 91:9;

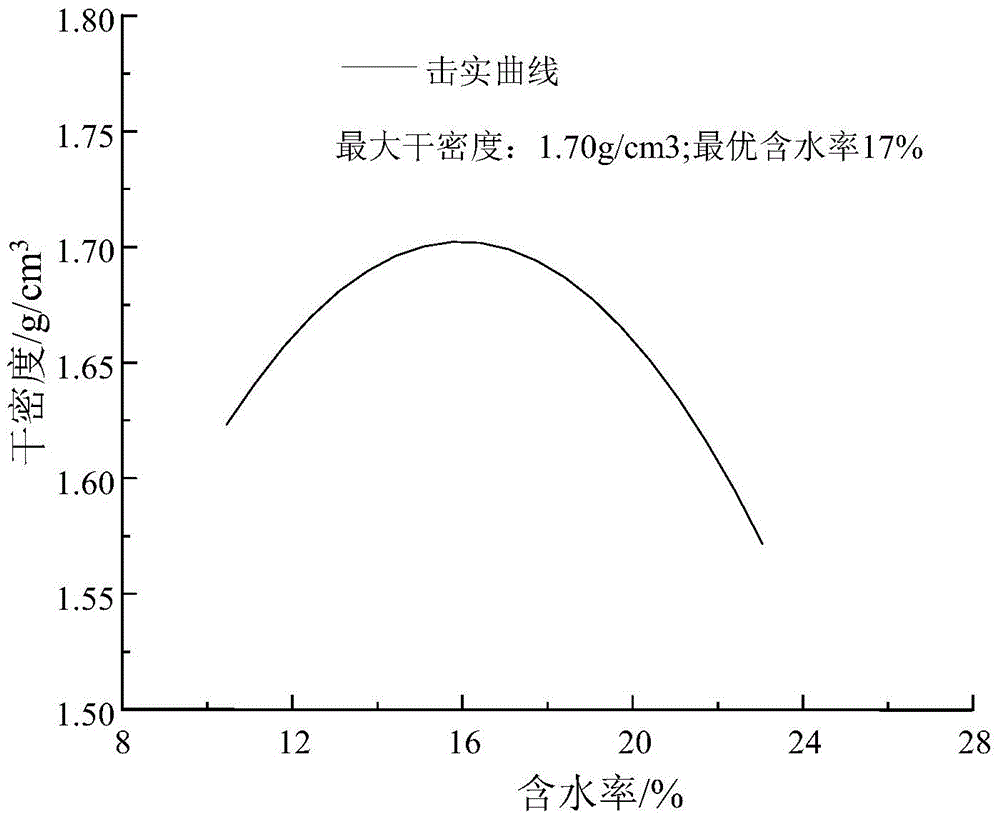

[0030] (3), carry out standard compaction test to mixture, obtain the optimum moisture content of mixture 17% and maximum dry density 1.70g / cm 3 ;

[0031] (4), mix the mixture of step (2) with water according to the optimal moisture content of 17%, and compact it into a dry density of 1.70g / cm after mixing evenly 3 The mixed soil samples were used for curing, and the curing period was 28 days to complete the loess modification treatment.

[0032] The hammer weight used in the standard compaction test in step (3) is 2.5kg, and the hammer bottom area is 19.64cm 2 , the drop distance is 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com